Method for synthesizing propionyl levo-carnitine hydrochlorate

A technology for synthesizing propionyl-L-carnitine and propionyl-L-carnitine, which is applied in the field of synthesis of aminocarboxylic acid compounds, can solve the problems of unsafe hazard, low boiling point of diethyl ether, waste of solvent, etc., so as to improve production efficiency and reduce solvent waste and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

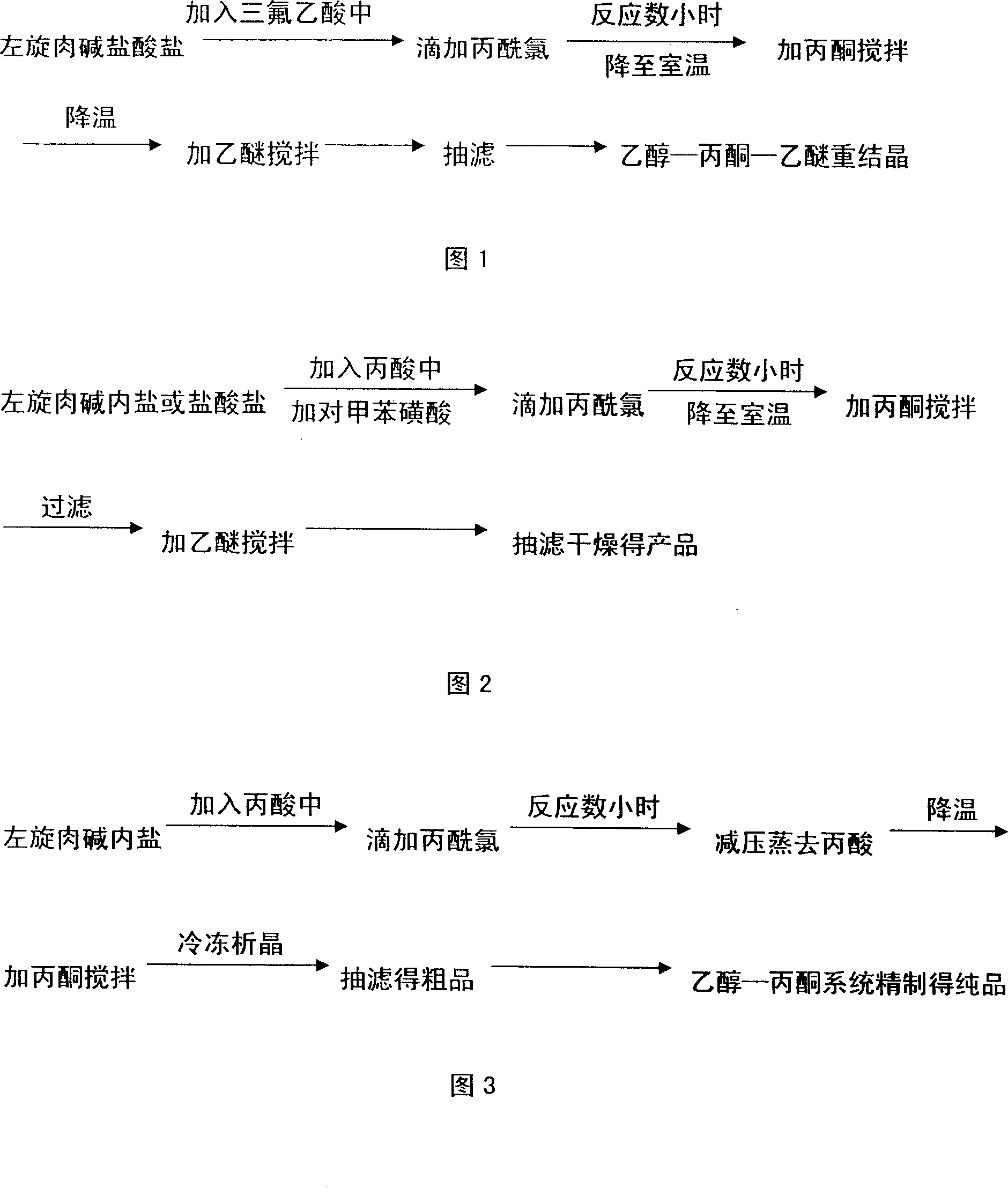

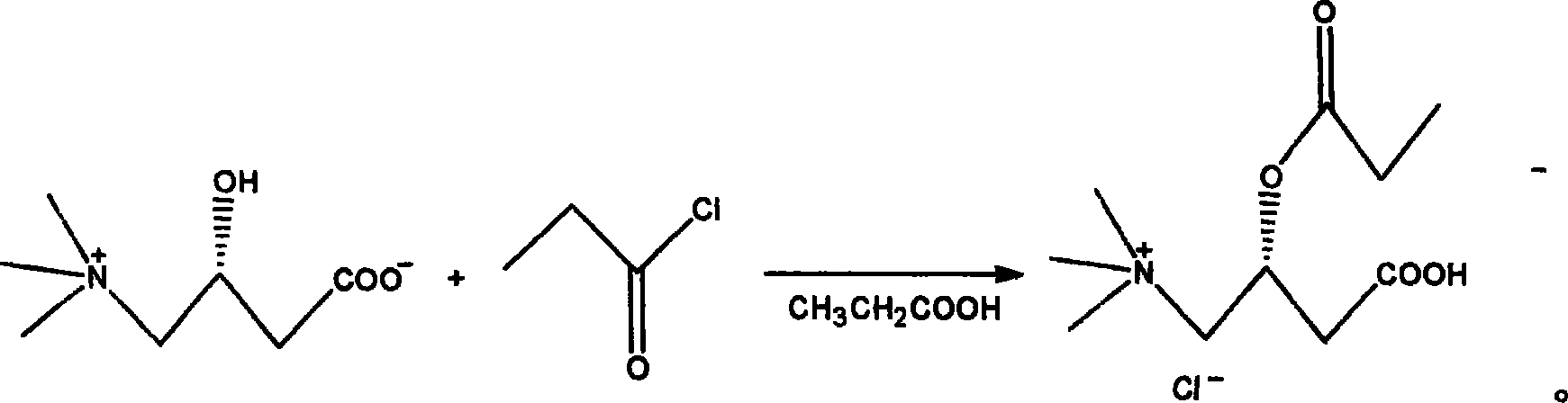

Method used

Image

Examples

Embodiment 1

[0031] Add 600g of propionic acid weighed into the reaction tank (1L), add 300g of L-carnitine inner salt under stirring to dissolve, after completely dissolving, add 207g of propionyl chloride dropwise; then raise the temperature to 70°C and keep the temperature for 2 hours; distill and concentrate under reduced pressure To crystallization, cool down and add 400g of acetone, fully stir and disperse for 0.5 hours, cool down and crystallize, and keep warm at 0-5°C for 2 hours; filter, wash the material with acetone, and suction filter to obtain the crude propionyl-L-carnitine hydrochloride. Vacuum -0.09Mpa and dry at 80°C. 427.8 g of the crude product was obtained with a yield of 96.3%.

[0032] Take 300 g of the dried crude product propionyl-L-carnitine hydrochloride, add it into a reactor containing 600 g of absolute ethanol and stir to dissolve; heat up to 50°C, and keep the temperature constant for 0.5 hours to ensure sufficient dissolution; Concentrate by pressure distill...

Embodiment 2

[0040] Add 600g of propionic acid that has been weighed into the reaction tank, add 300g of L-carnitine inner salt under stirring to dissolve, and after it is completely dissolved, add 207g of propionyl chloride dropwise; then raise the temperature to 70°C and keep the temperature for 6 hours; distill under reduced pressure and concentrate until crystallization , add 500g of acetone at lower temperature, fully stir and disperse for 0.5 hours, lower the temperature and crystallize, and keep warm at 0-5°C for 2 hours; filter and suction filter to obtain crude propionyl-L-carnitine hydrochloride, and dry at 80°C with vacuum -0.09Mpa 449.1 g of crude product was obtained with a yield of 95.2%.

[0041] Take 300 g of the dried crude product propionyl-L-carnitine hydrochloride, add it into a reactor containing 600 g of absolute ethanol and stir to dissolve; heat up to 50°C, and keep the temperature constant for 0.5 hours to ensure sufficient dissolution; Concentrate by pressure dist...

Embodiment 3

[0043] Add 15 kg of propionic acid that has been weighed into the reaction tank, add 10 kg of L-carnitine inner salt under stirring to dissolve, and after it is completely dissolved, add 7.2 kg of propionyl chloride dropwise; then raise the temperature to 70°C and keep the temperature for 6 hours; crystallization, add 24kg of acetone at lower temperature, fully stir and disperse for 1 hour, lower the temperature to crystallize, and keep warm for 2 hours at 0-5°C; 0.09Mpa was dried at 80°C to obtain 451.5g, with a yield of 95.7%.

[0044]Take 30kg of dried crude product propionyl-L-carnitine hydrochloride, add it into a reactor containing 60kg of absolute ethanol and stir to dissolve; heat up to 50°C, and keep the temperature constant for 1 hour to ensure sufficient dissolution; Concentrate by pressure distillation, evaporate about 40kg of ethanol, then lower to 40°C, add 50kg of acetone to stir and disperse, cool to 0-10°C for crystallization for 1 hour; then filter, spin dry,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com