Photoelectric device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

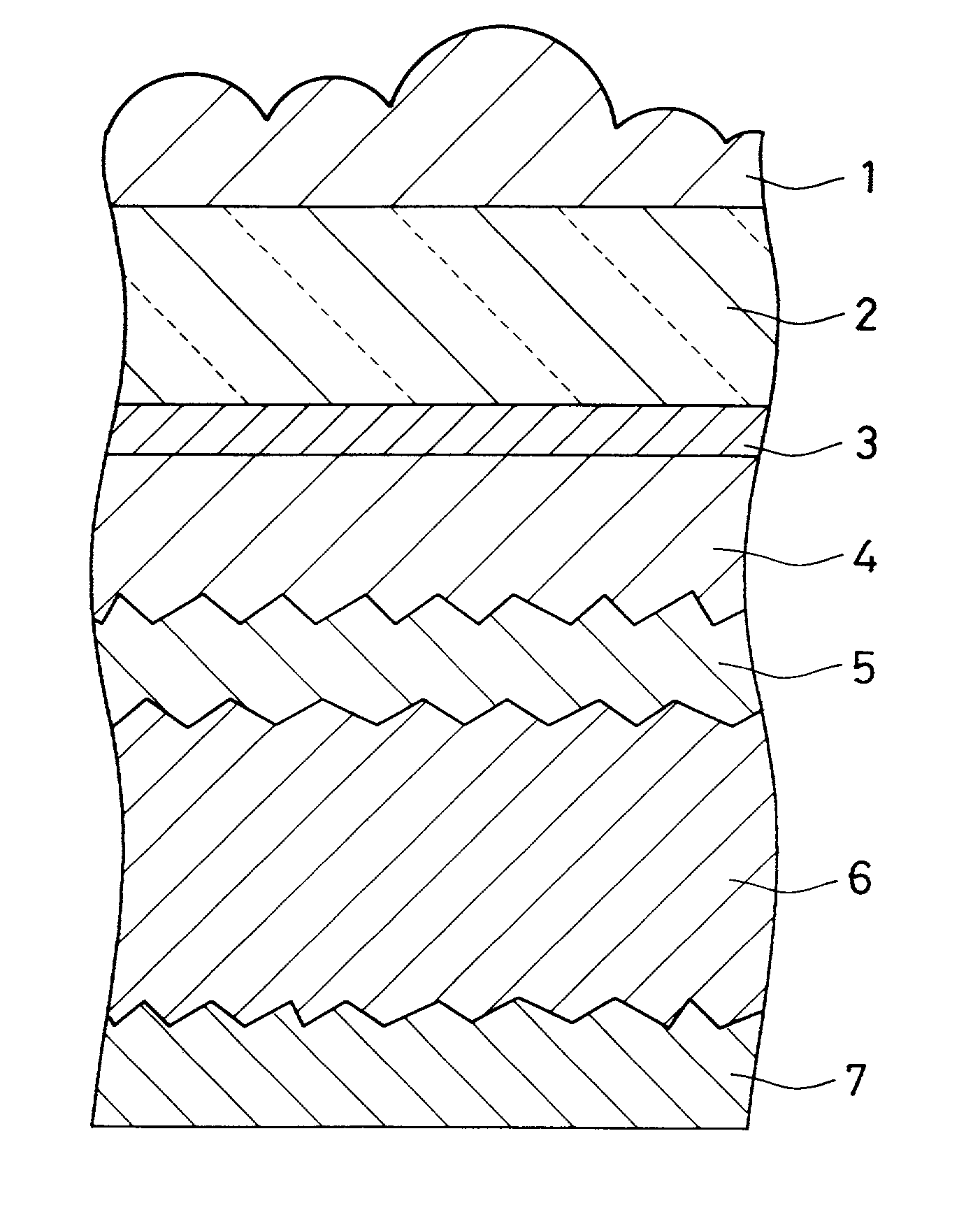

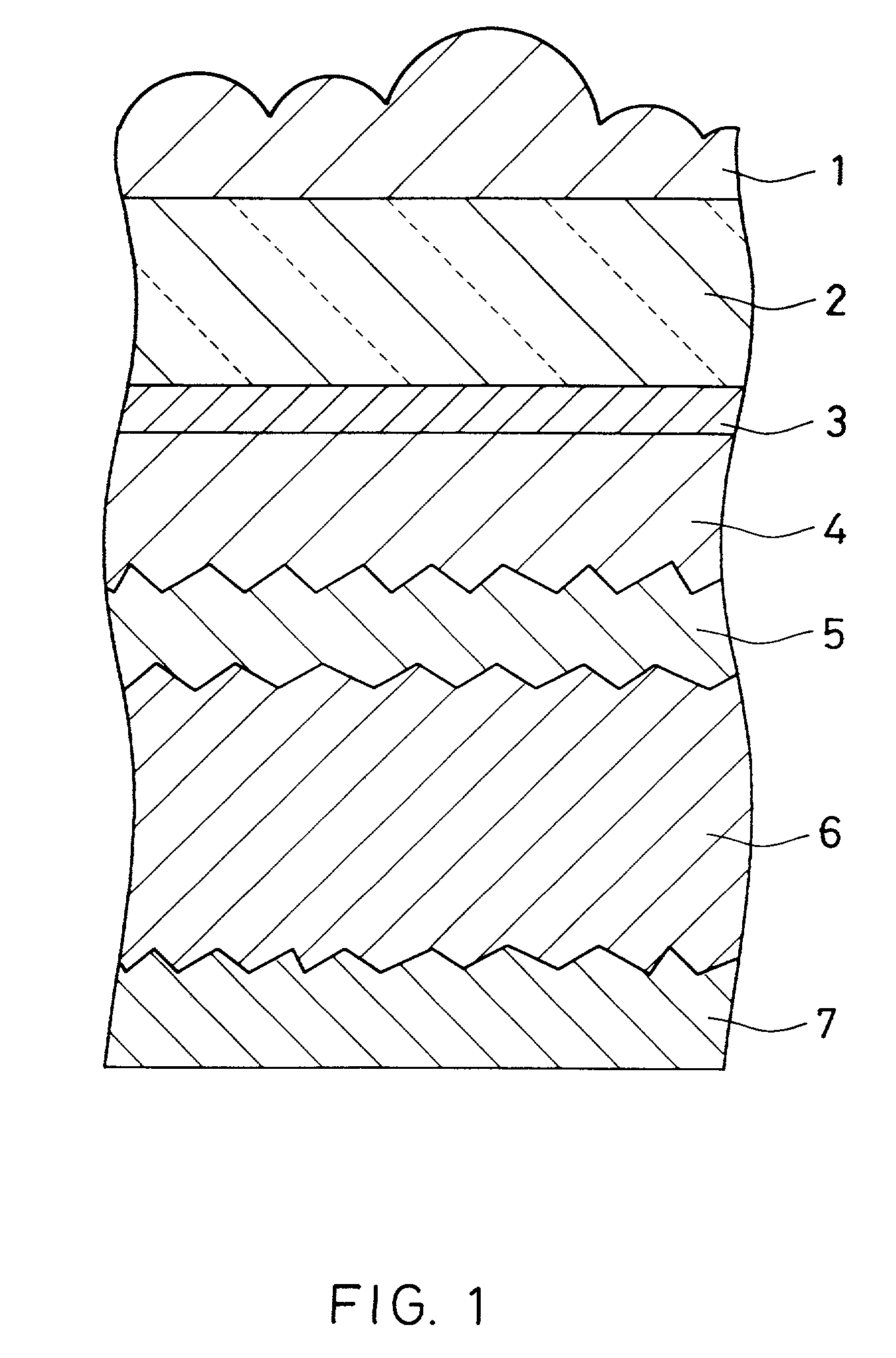

Image

Examples

Embodiment Construction

[0061] Hereinafter, the present invention will be described more specifically by way of example, but is not limited thereto.

[0062] Manufacture of Glass Sheet with Transparent Conductive Film

[0063] Sample 1

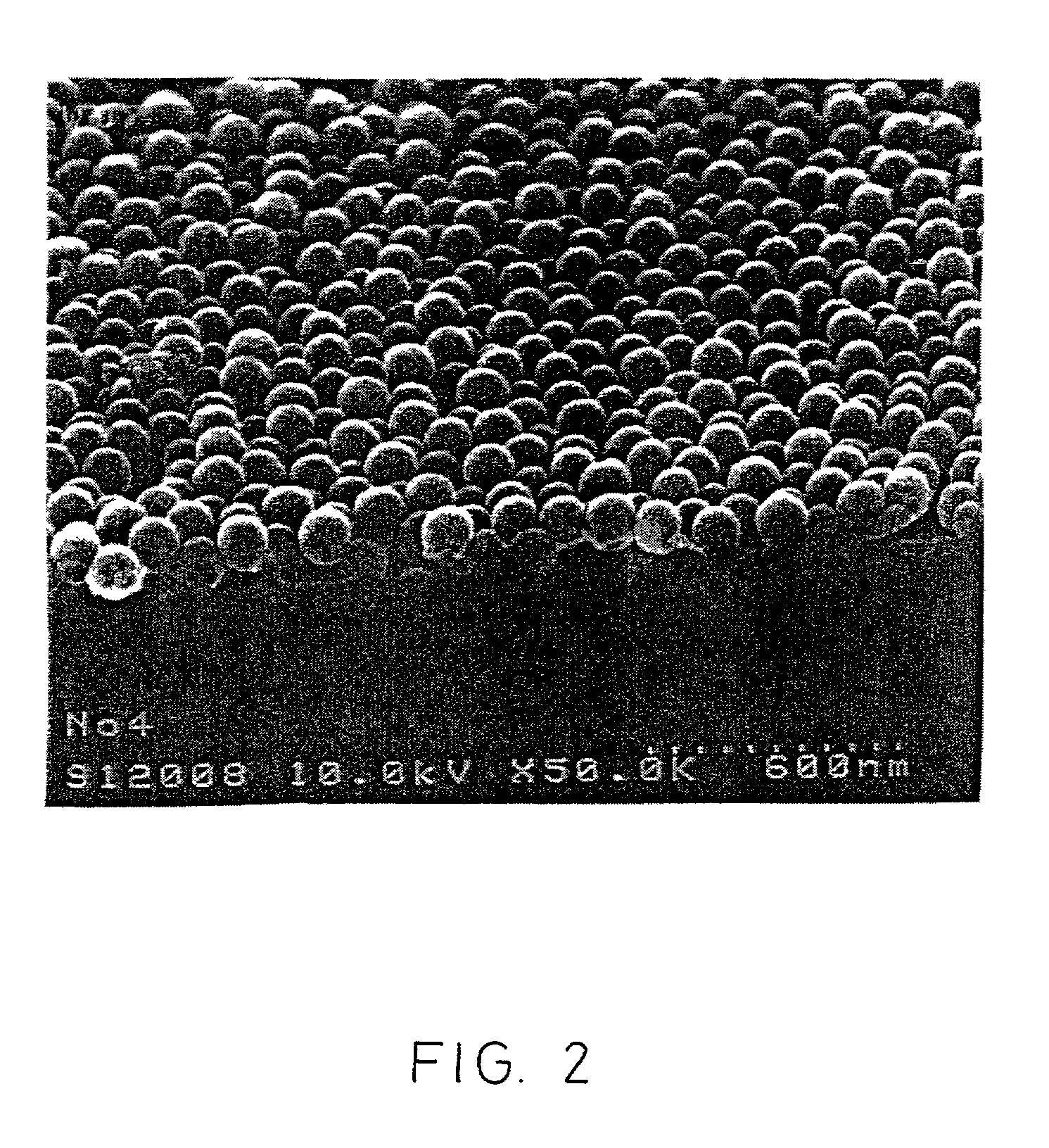

[0064] In a production line for float glass, a tin oxide film (SnO.sub.2 film), a silicon oxide film (SiO.sub.2 film), and a fluorine-containing tin oxide film (SnO.sub.2:F film) were formed in this order on a glass ribbon using a plurality of coaters arranged in a float bath. The glass ribbon is formed to have a thickness of 4 mm and the total amount of iron oxide of 0.01 wt % in terms of Fe.sub.2O.sub.3.

[0065] Specifically, the glass ribbon had a temperature of about 650.degree. C. immediately before reaching a coater located at the furthest upstream position, and a mixed gas of dimethyltin dichloride (vapor), oxygen and nitrogen was supplied from the coater, so that a SnO.sub.2 film having a thickness of 25 nm was formed on the glass ribbon. Then, a mixed gas of monosilane, ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com