Semiconductor laser device

A technology of lasers and semiconductors, applied in semiconductor laser devices, semiconductor lasers, laser devices, etc., can solve problems such as inability to fully satisfy temperature characteristics, high polarization ratio, etc., and achieve improved photoelectric conversion efficiency, high polarization ratio, and improved heat release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

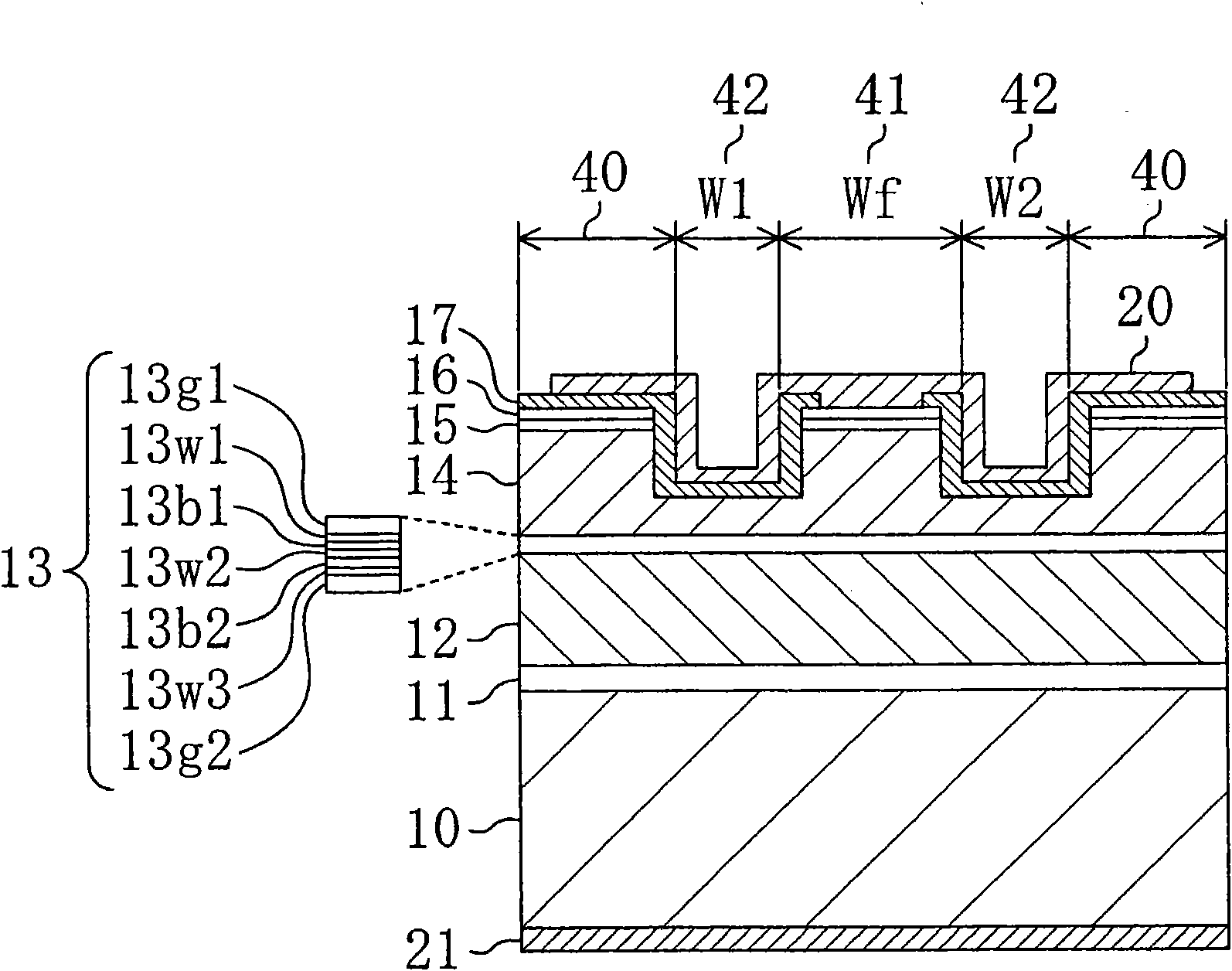

[0124] figure 1 The cross-sectional structure of the semiconductor laser device according to the first embodiment of the present invention is shown.

[0125] In this configuration, a red laser and an infrared laser are integrated on an n-type GaAs substrate 10 whose main surface is a surface inclined at 10° from the (100) plane to the [011] direction. First, explain figure 1 Construction of the red laser shown.

[0126] The red laser is formed with n-type GaAs buffer layer 11 (0.5 μm), n-type (Al 0.7 Ga 0.3 ) 0.51 In 0.49 P cladding layer 12 (2.0μm), distorted quantum well active layer 13, p-type (Al 0.7 Ga 0.3 ) 0.51 In 0.49 P cladding layer 14, p-type Ga 0.51 In 0.49 P protective layer 15 p-type GaAs contact layer (0.4 μm) 16 . Distorted quantum well active layer 13 is as shown in the figure (Al 0.5 Ga 0.5 ) 0.51 In 0.49 A stacked structure of P first guide layer 13g1, GaInP well layer 13w1-w3, AlGaInP barrier layers 13b1, 13b2, and AlGaInP second guide l...

no. 2 Embodiment approach

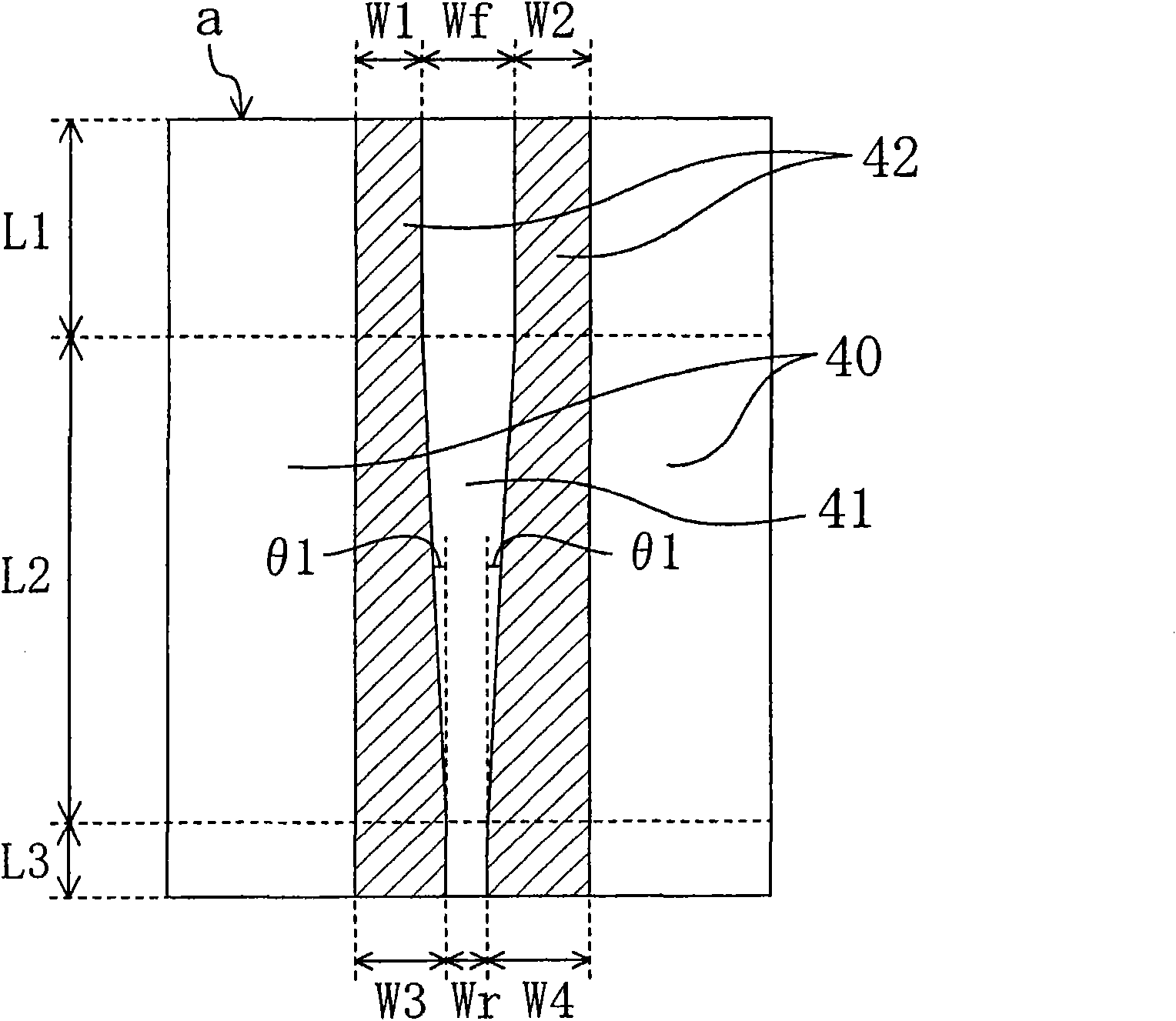

[0153] Figure 9 The ridge shape and the wing region shape of the semiconductor laser device according to the second embodiment of the present invention are shown. In addition, the shape of the ridge 41 is the same as the structure of the ridge 41 described in the first embodiment of the present invention (refer to figure 2 ).

[0154] Figure 9 The wing region 40 shown increases the width of the groove 42 within the region of the tapered shape where the ridge width decreases with respect to the resonator direction, so that the distance between the central portion of the ridge 41 and the wing region 40 increases. When the shape of the ridge 41 is tapered, the propagating light of the waveguide leaks from the sidewall of the ridge 41 , and the scattered light diffuses into the wing region 40 . When the scattered light reaches the wing region 40, there is a difference in effective refractive index between the wing region 40 and the groove 42, so it is reflected at the interf...

Deformed example 1-

[0161] Figure 11 The ridge shape and the shape of the wing region in Modification 1 of the semiconductor laser device according to the second embodiment of the present invention are shown. In addition, the shape of the ridge 41 is the same as the structure of the ridge 41 described in the first embodiment of the present invention (refer to figure 2 ).

[0162] Figure 11 The wing region 40 is shown increasing in width from the front end to the rear end face of the groove 42 so that the distance between the central portion of the ridge 41 and the wing region 40 increases.

[0163] Such a structure can also prevent a decrease in kink light output. In Modification 1, the widths W1 and W2 are set to 6 μm, and the widths W3 and W4 are set to 11 μm in order to improve the kink light output and realize FFP without disturbance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com