Multi component controlled release system for oral care, food products, nutraceutical, and beverages

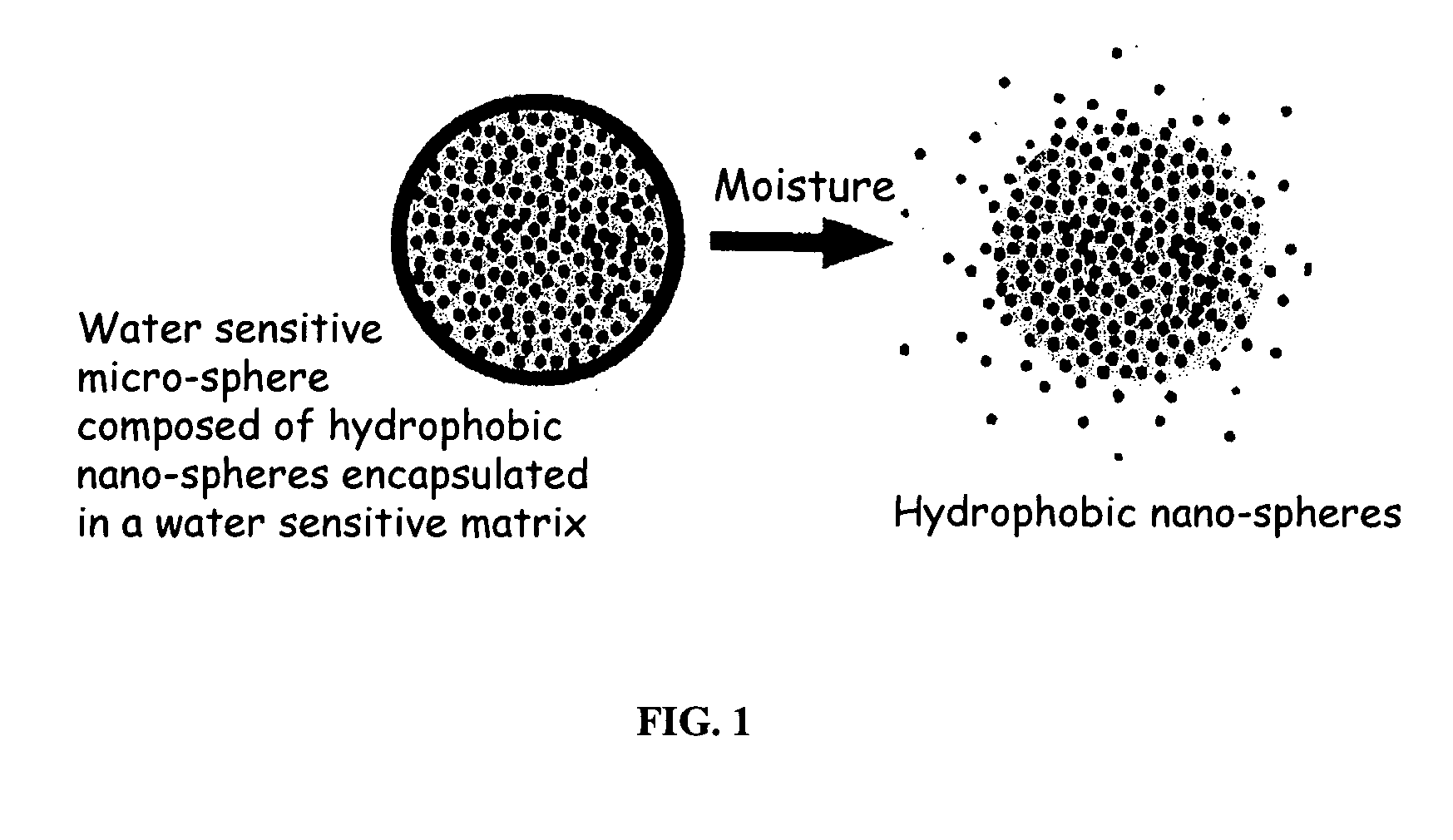

a multi-component, controlled release technology, applied in the direction of chewing gum, prosthesis, metabolic disorder, etc., can solve the problems of significant active agents volatilizing or oxidizing, limited to lipophilic flavoring agents, and drastically limited the application of coacervation for flavor encapsulation in the food industry. , to achieve the effect of prolonging the residence time of active agents in the oral cavity, prolonging the sensation in the mouth, and enhancing the stability and bioavail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0141] The following procedure is used for the preparation of a controlled release system that provides flavor transition as well as delivers vitamin E for extended period of time. A peppermint flavor and vitamin E are encapsulated in the hydrophobic nanospheres and a fruity flavor is encapsulated in the water sensitive microsphere. The nanospheres hydrophobic matrix is candelilla wax, commercially available from Strahl & Pitsch Inc. of West Babylon, N.Y. The microsphere water sensitive matrix is Hi-Cap™ 100 (commercially available from the National Starch and Chemical Company of Bridgewater, N.J.).

[0142] 100 grams of candelilla wax is placed in an oven at 80° C. and allowed to melt. 1500 grams of deionized water are placed into 1 gallon vessel, fitted with an all-purpose silicon rubber heater (Cole-Palmer Instrument Company). 500 grams of Hi-Cap™ 100 (commercially available from the National Starch and Chemical Company of Bridgewater, N.J.) was added to the water and the aqueous s...

example 2

[0143] The following procedure is used for the preparation of a controlled release system that provides flavor transition as well as releases a cooling agent for extended period of time. A cooling agent (WS-3 commercially available from Millennium Specialty Chemicals, of Jacksonville, Fla.) is encapsulated in the hydrophobic nanospheres and a fruity flavor (commercially available from Noville Inc. of South-Hackensack, N.J.) is encapsulated in the water sensitive microsphere. The nanospheres hydrophobic matrix is candelilla wax, commercially available from Strahl & Pitsch Inc. of West Babylon, N.Y. The microsphere water sensitive matrix is Hi-Cap™ 100 (commercially available from the National Starch and Chemical Company of Bridgewater, N.J.).

[0144] 150 grams of candelilla wax is placed in an oven at 80° C. and allowed to melt. 1500 grams of deionized water are placed into 1 gallon vessel, fitted with an all-purpose silicon rubber heater (Cole-Palmer Instrument Company). 450 grams of...

example 3

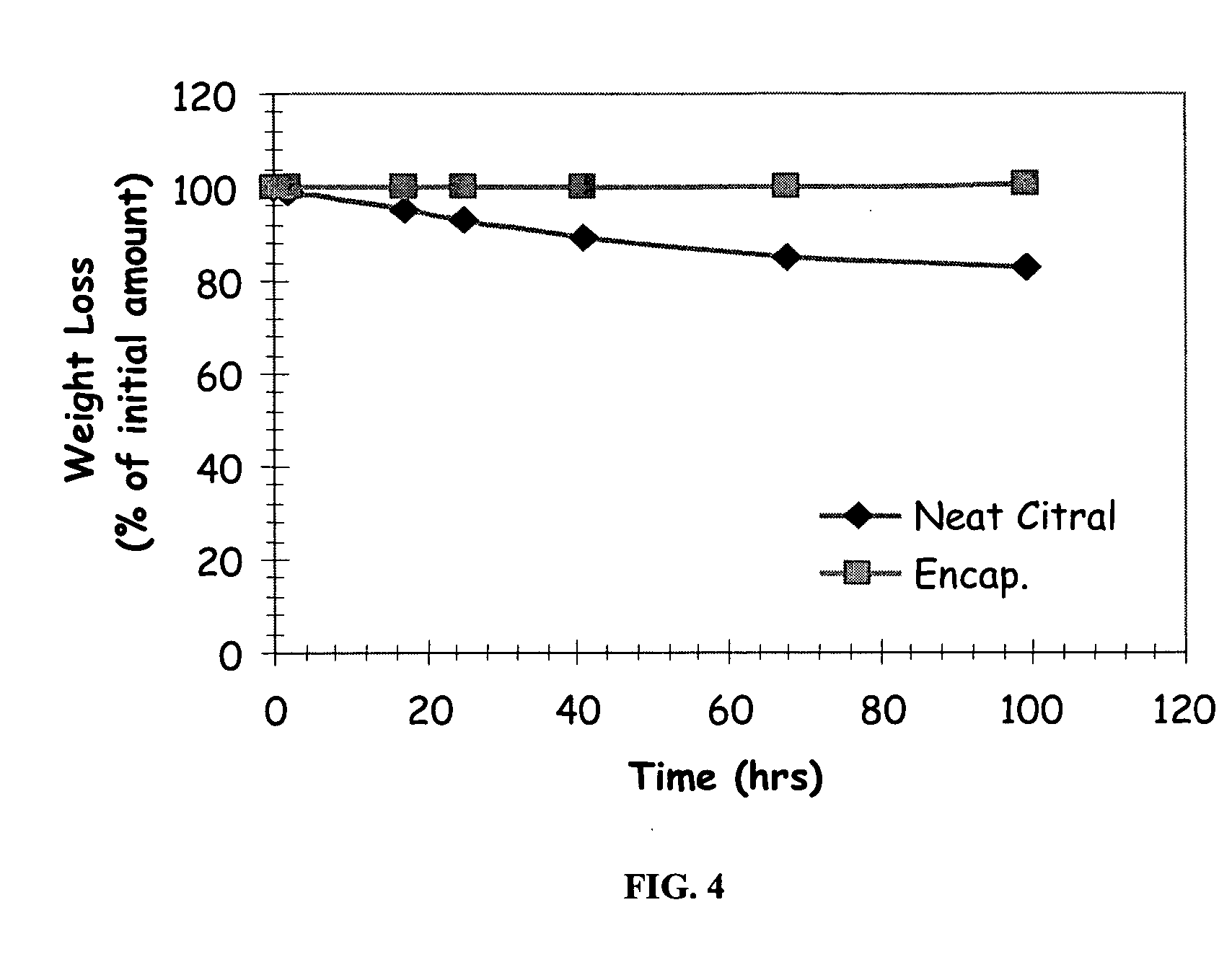

[0145] The following procedure is used for the preparation of a controlled release system that protect citral against oxidation and provides long lasting citrus mouth feel for extended period of time, by encapsulating citral in the hydrophobic nanospheres. The nanospheres hydrophobic matrix is camauba wax, commercially available from Strahl & Pitsch Inc. of West Babylon, N.Y. The microsphere water sensitive matrix is Hi-Cap™ 100 (commercially available from the National Starch and Chemical Company of Bridgewater, N.J.).

[0146] 250 grams of camauba wax (commercially available from Strahl & Pitsch Inc. of West Babylon, N.Y.) and 50 grams of polysorbate 80 (commercially available under the trade name T-MAZ® 80K from BASF of Mt. Olive, N.J.) are placed in an oven at 90° C. and allowed to melt. 1800 grams of deionized water are placed into 1 gallon vessel, fitted with an all-purpose silicon rubber heater (Cole-Palmer Instrument Company). 500 grams of Hi-Cap™ 100 (commercially available f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com