Methods of preparing gaseous precursor-filled microspheres

a precursor and gaseous technology, applied in the field of gaseous precursor-filled liposome preparation methods and apparatus, can solve the problems of inability to carry out portable examination, inability to perform mri, and unknown dangers of x-rays, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

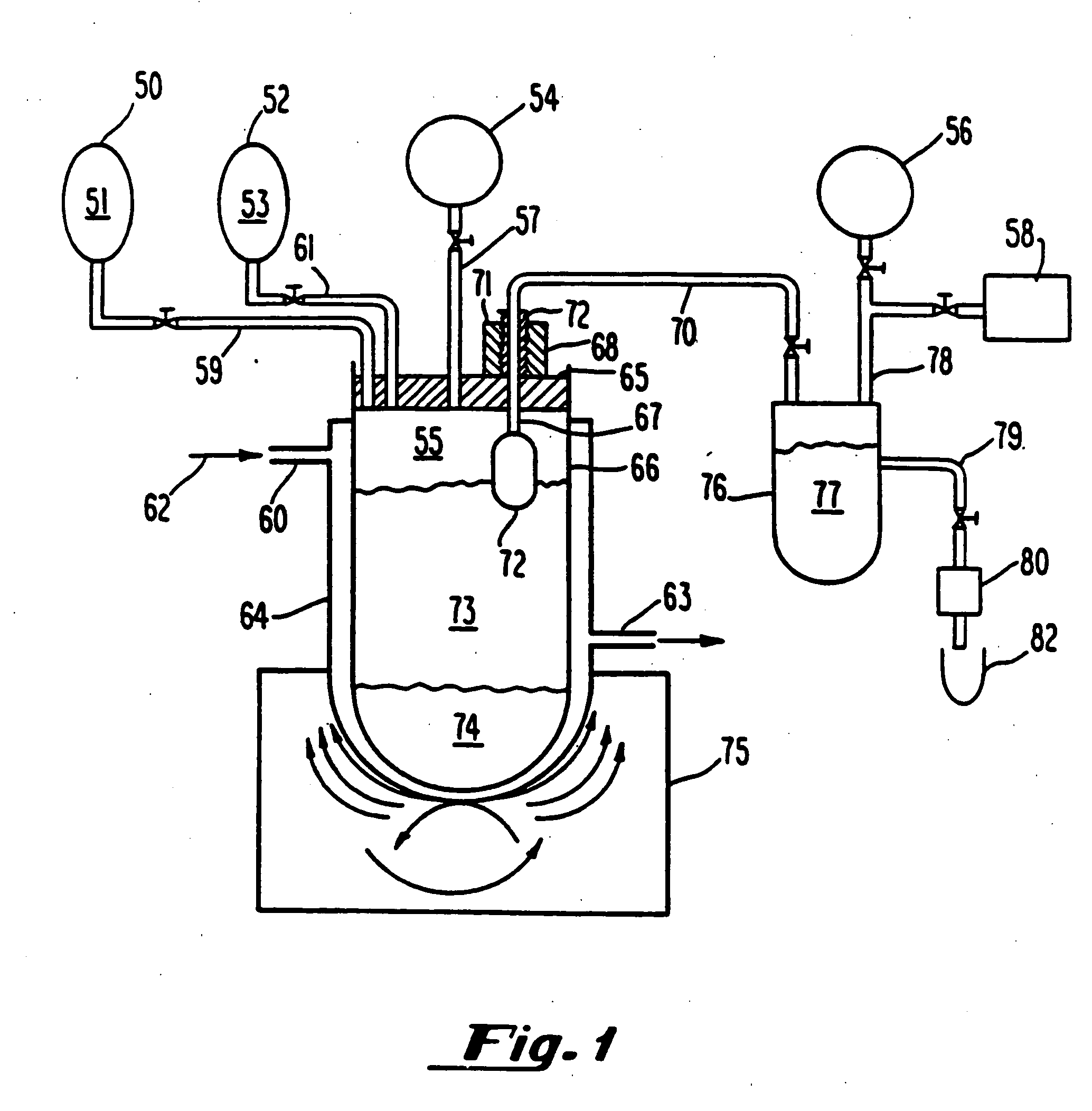

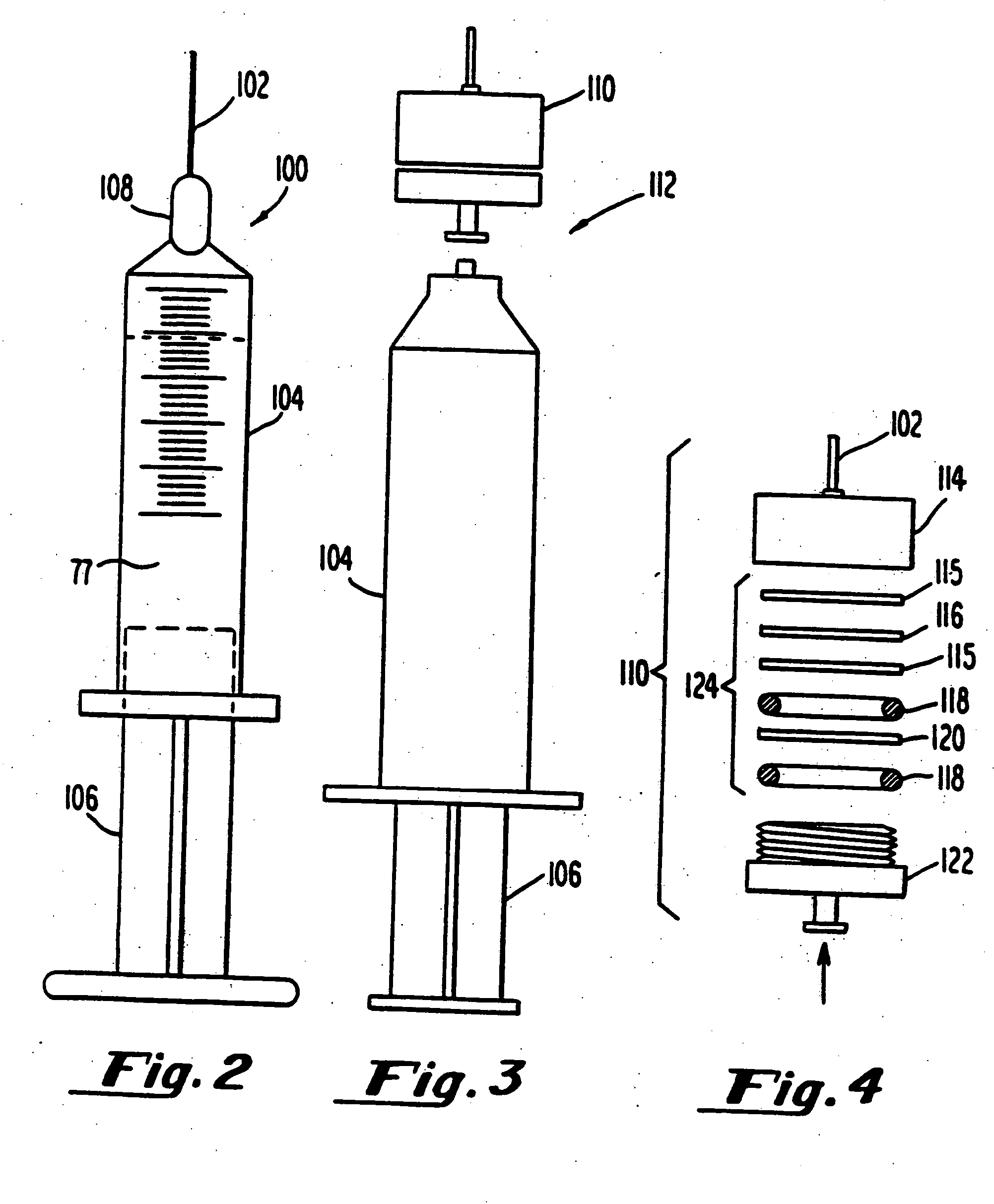

Method used

Image

Examples

example 1

Preparation of Gas-Filled Lipid Spheres from Perfluorobutane

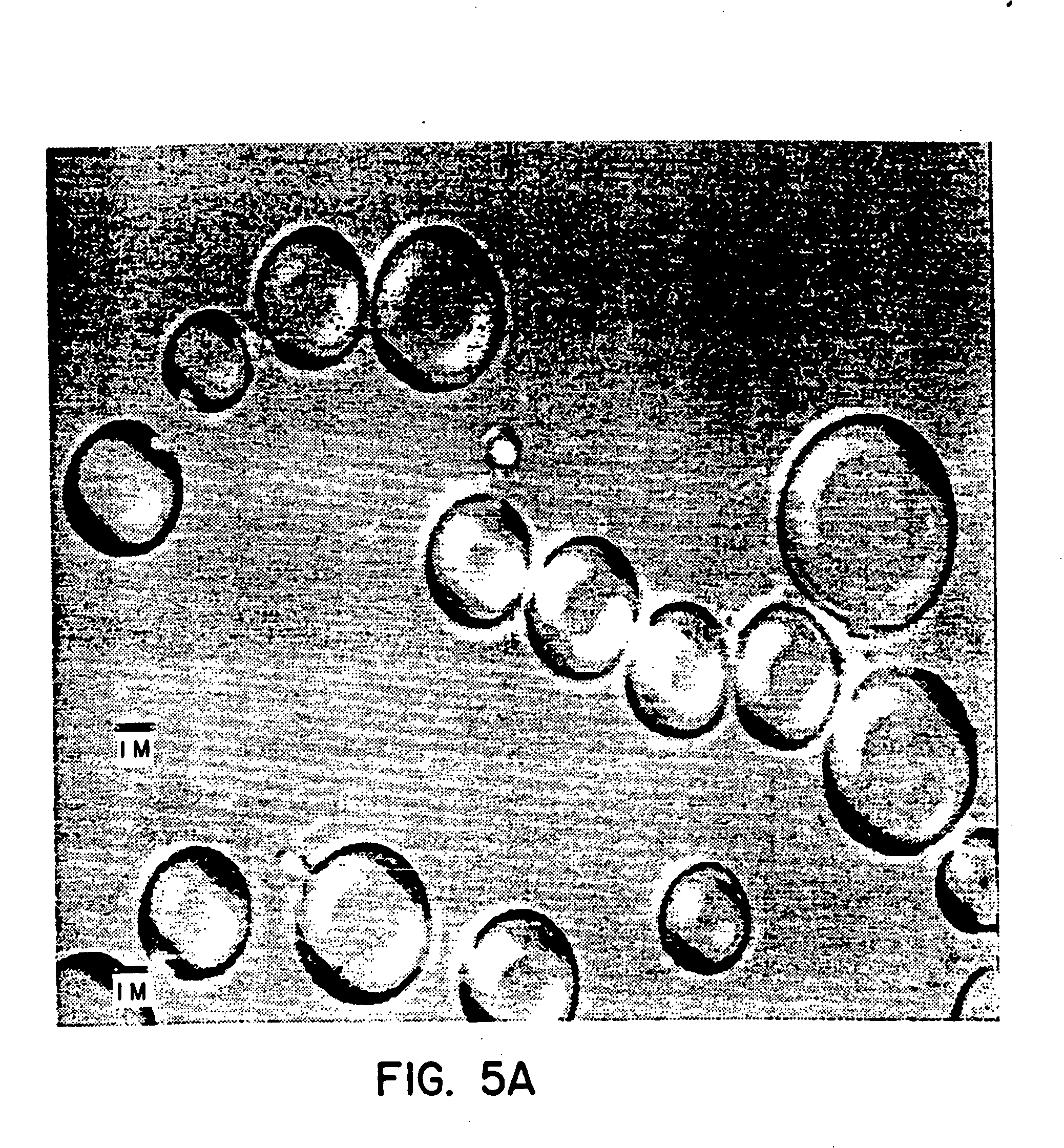

[0219] Gaseous precursor-containing liposomes were prepared using perfluorobutane (Pfaltz and Bauer, Waterbury, Conn.) as follows: A 5 mL solution of lipid, 5 mg per ml, lipid=87 mole percent DPPC, 8 mole percent DPPE-PEG 5,000, 5 mole percent dipalmitoylphosphatidic acid (all lipids from Avanti Polar Lipids, Alabaster, Ala.), in 8:1:1 normal saline:glycerol:propylene glycol, was placed in a glass bottle with a rubber stopper (volume of bottle=15.8 ml). Air was evacuated from the bottle using a vacuum pump, Model Welch 2-Stage DirecTorr Pump (VWR Scientific, Cerritos, Calif.) by connecting the hose to the bottle through a 18 gauge needle which perforated the rubber stopper. After removing the gas via vacuum, perfluorobutane was placed in the stoppered bottle via another 18 gauge needle connected to tubing attached to the canister of perfluorobutane. This process was repeated 5 time such that any traces of air were removed ...

example 2

Preparation of Gaseous Precursors Via Microfluidization

[0223] Gaseous precursor-filled lipid bilayers were prepared as in Example 1 except, after addition of the gaseous precursor, the contents were microfluidized through six passes on a Microfluidics microfluidizer (Microfluidics Inc., Newton, Mass.). The stroke pressure ranged between 10,000 and 20,000 psi. Continuing with the preparation as per Example 1, produced gas-filled lipid bilayers with gaseous precursor encapsulated.

example 3

Formulation of Gas-Filled Lipid Bilayers using Phosphatidic Acid and Dipalmitoyphosphatidylcholine

[0224] Gas-filled lipid bilayers were prepared as set forth in Example 6 except for the fact that DPPC was used in combination with 5 mole % phosphatidic acid (Avanti Polar Lipids, Alabaster, Ala.). Formulation of gas-filled lipid bilayers resulted in an increase in solubility as exemplified by a decrease in the amount of lipid particulate in the lower aqueous vehicle layer. Resultant sizing appeared to decrease the overall mean size vs. DPPC alone to less than 40 μm.

EXAMPLE 4

Formulation of Gas-Filled Lipid Bilayers using Phosphatidic Acid, Dipalmitoylphosphatidylethanolamine-PEG 5,000 and Dipalmitoylphosphatidylcholine

[0225] Perfluorobutane encapsulated lipid bilayers were formed as discussed in Example 3 except that the lipid formulation contained 82% dipalmitoylphosphatidylcholine, 10 mole % dipalmitoylphosphatidic acid, and 8 mole % dipalmitoylphosphatidylethanolamine-PEG 5,000 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com