Thick-film dielectric and conductive compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

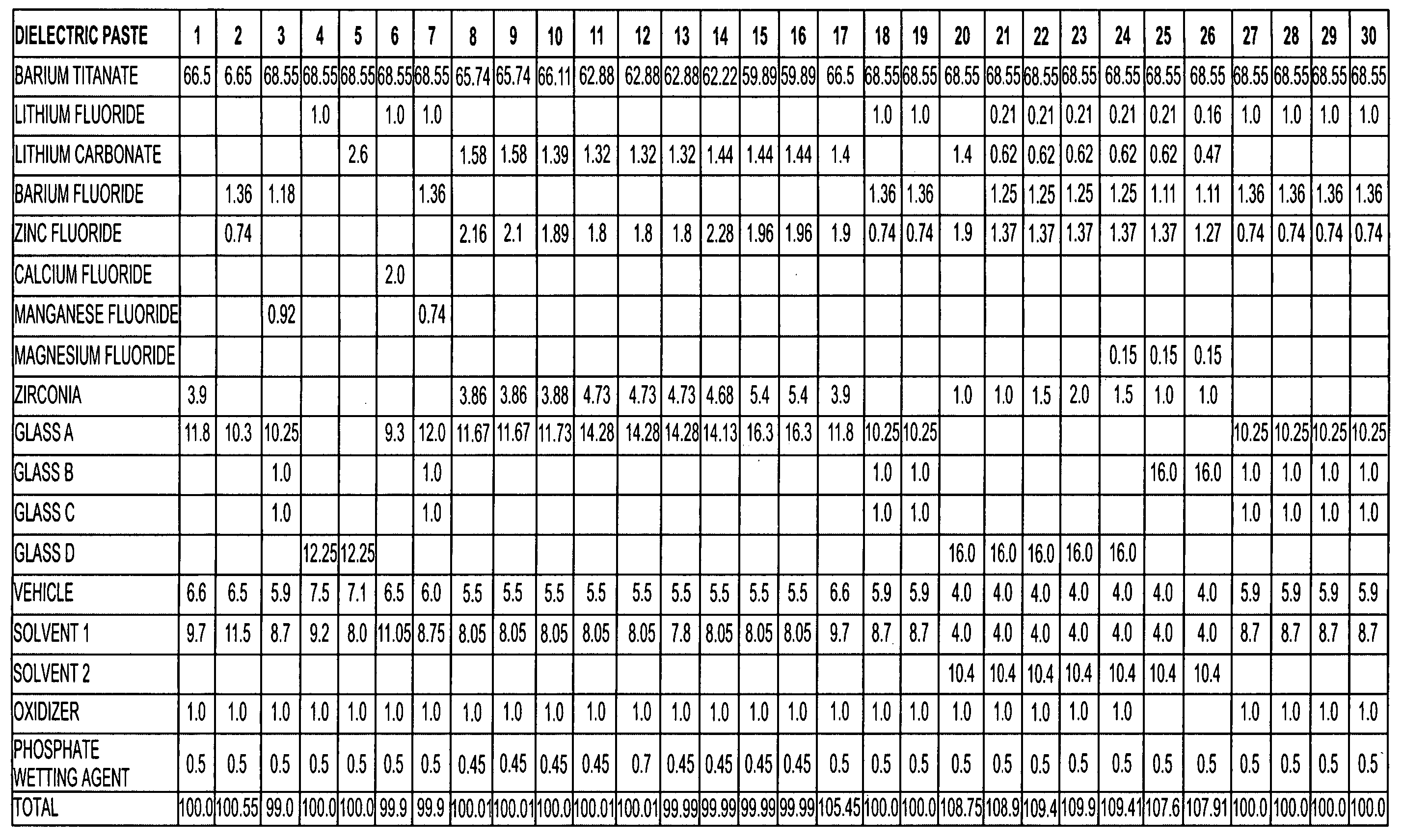

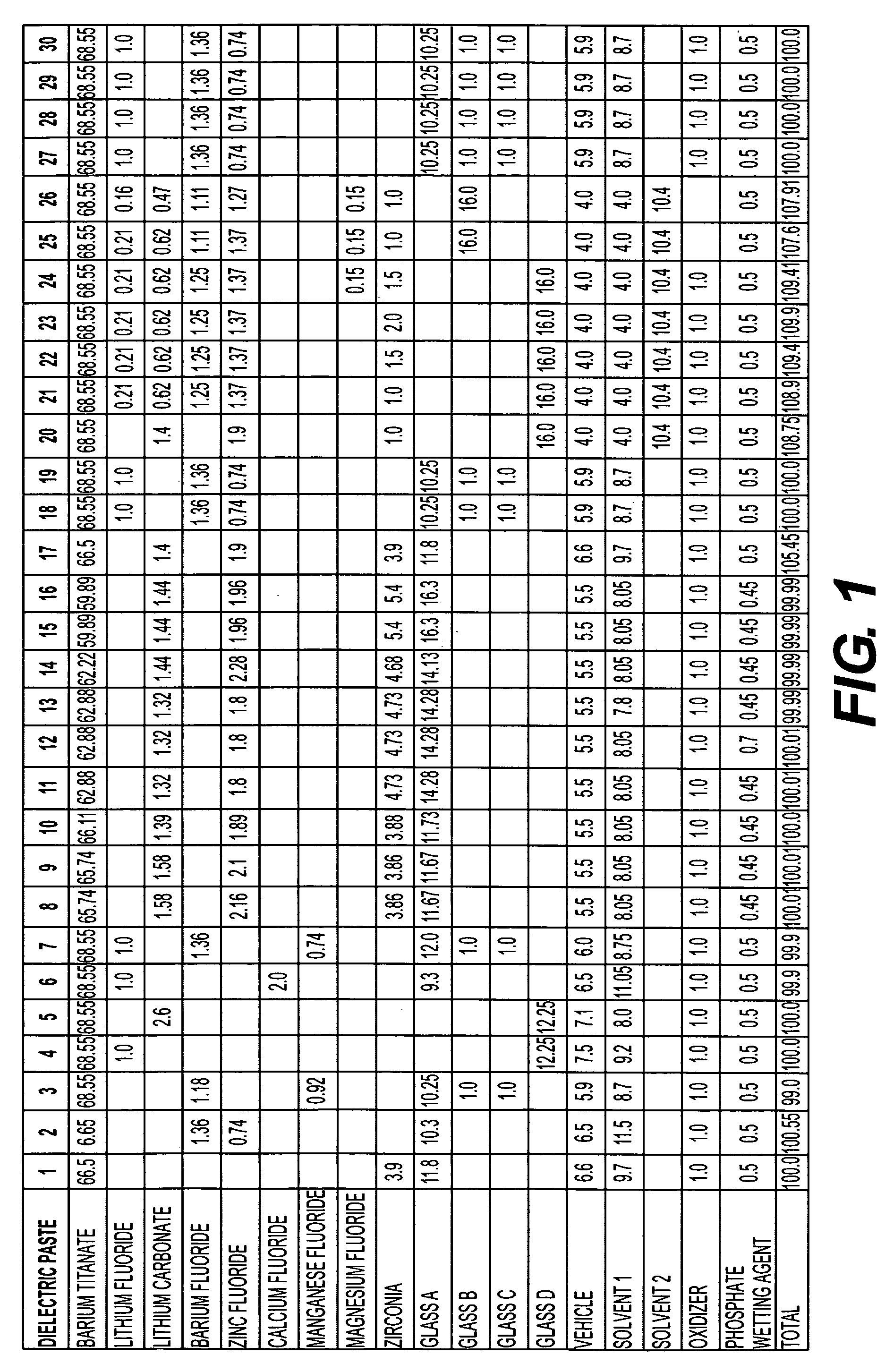

[0017] The invention concerns: (1) high dielectric constant thick-film barium titanate-based dielectric powder and paste compositions; (2) conductive powder and paste compositions; and (3) capacitors and other components formed using dielectric paste and conductive paste embodiments. Thus, in this detailed description, high dielectric constant thick-film barium titanate-based dielectric powder and paste compositions are disclosed; copper thick-film electrode powder and paste compositions are also disclosed; and fired-on-foil circuit components are disclosed. The high dielectric constant thick-film barium titanate-based dielectric paste compositions and the copper thick-film electrode paste compositions discussed in this specification may be used, for example, to form fired-on-foil passive circuit components. The thick-film barium titanate-based dielectric powder and paste compositions are used to form dielectrics having high dielectric constants (K) after firing.

[0018] The dielectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com