Method and apparatus for nitride spacer etch process implementing in situ interferometry endpoint detection and non-interferometry endpoint monitoring

a technology of in situ interferometry and etching process, which is applied in the direction of electrical apparatus, basic electric elements, electric discharge tubes, etc., can solve the problems of inability to reliably and efficiently etch endpoint detection, disfavored gate oxide change, and inability to detect gate oxide changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

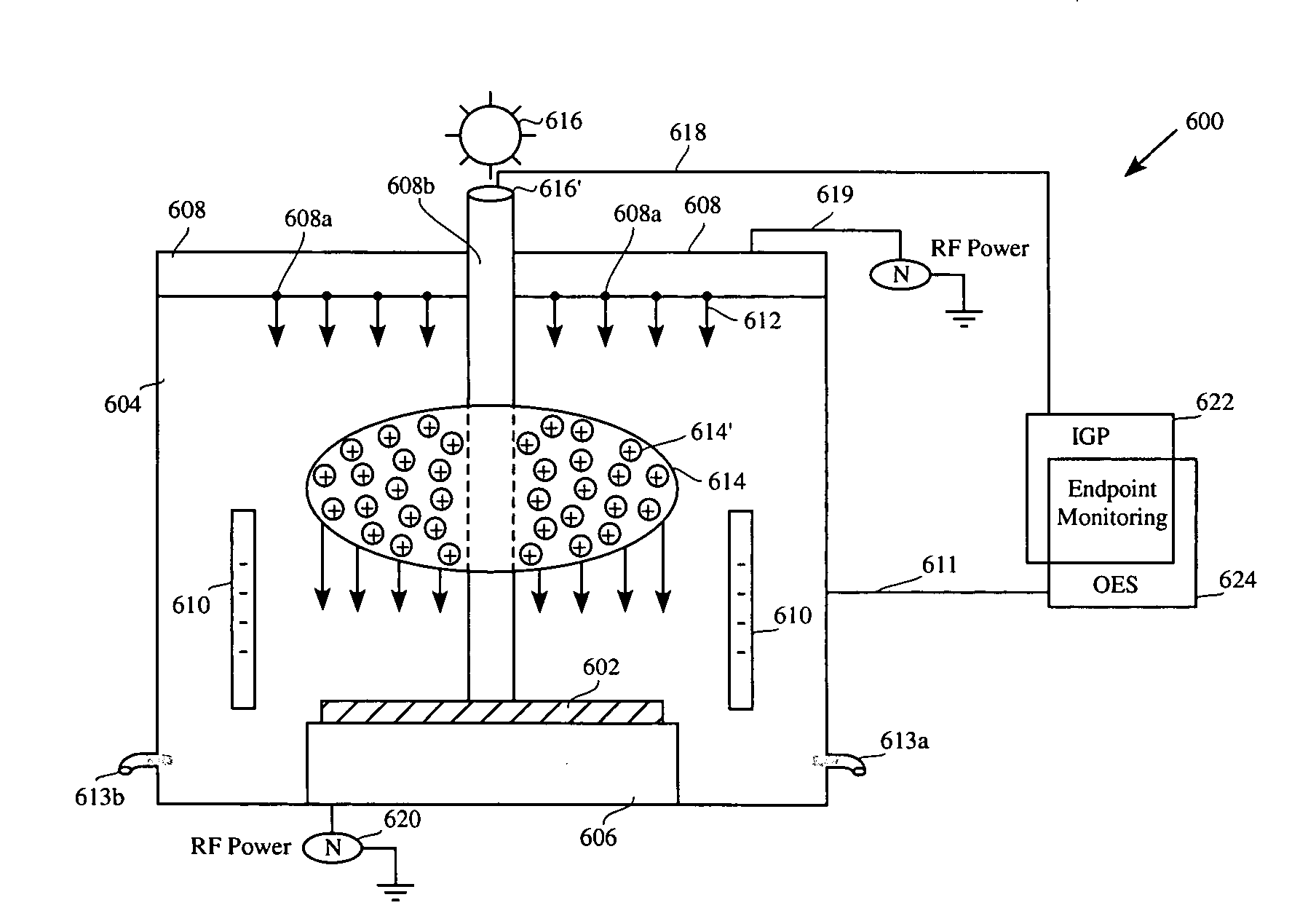

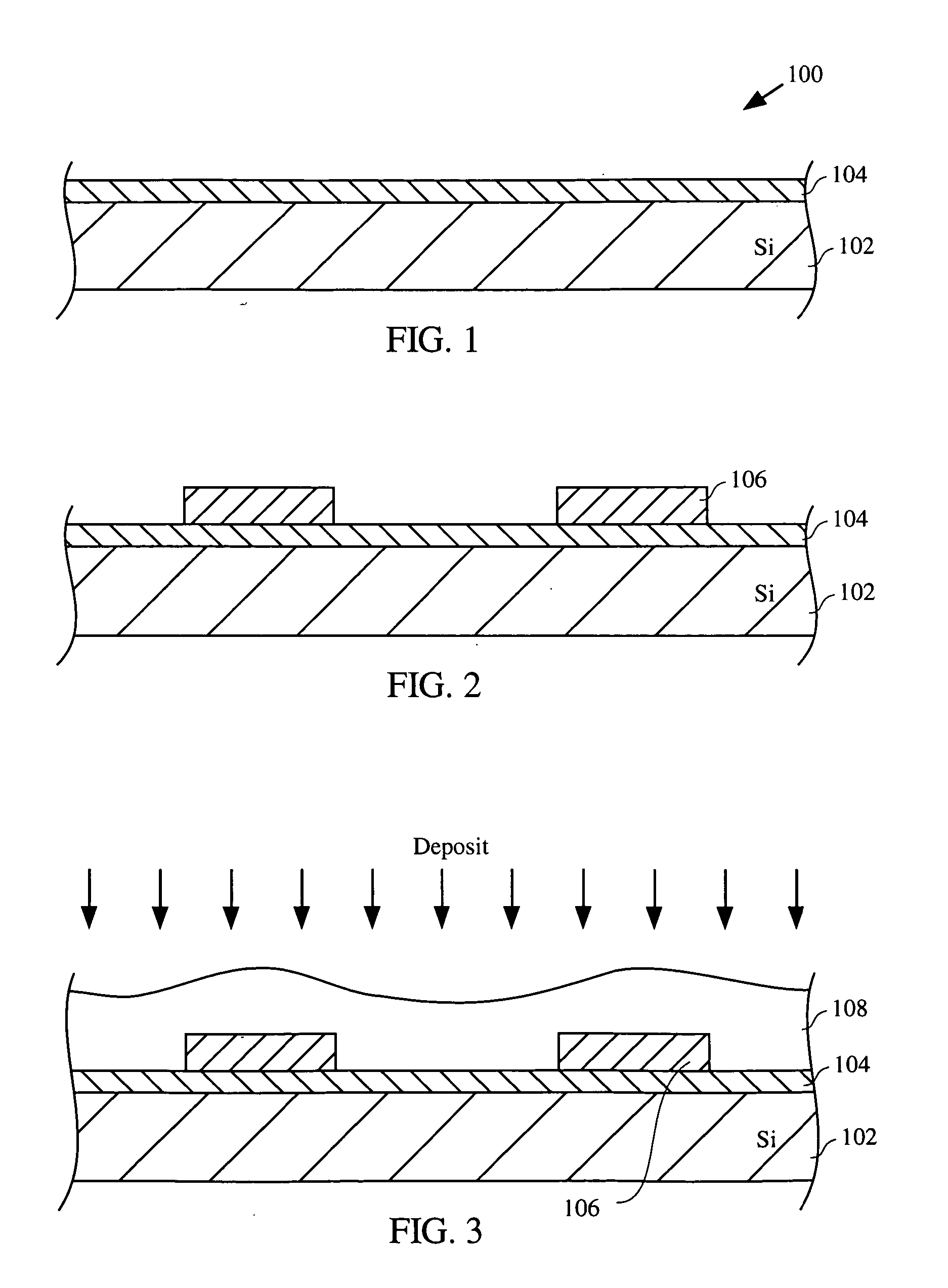

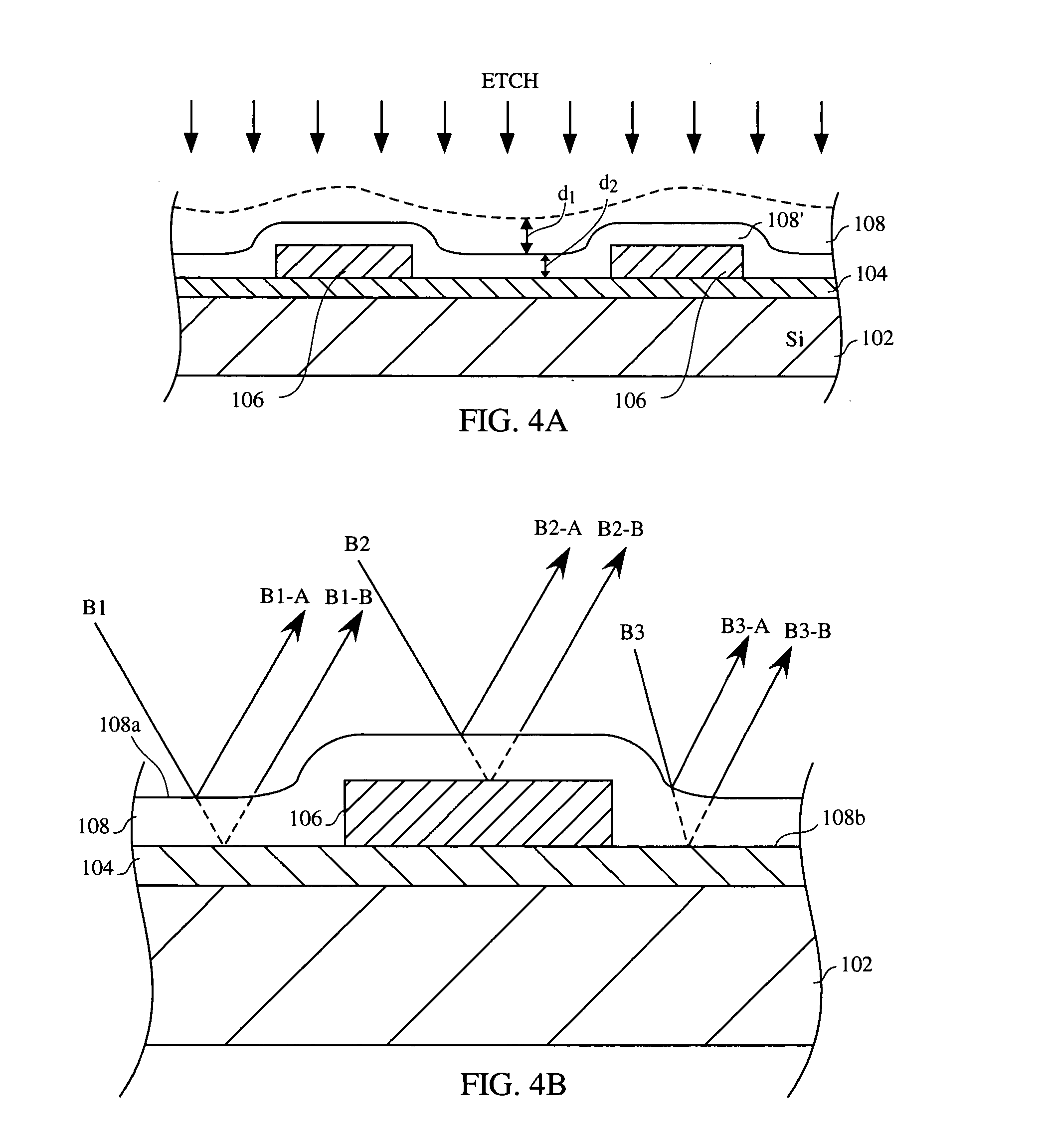

[0033] An invention for increasing wafer throughput through implementing an in-situ two-step etch process, is disclosed. Preferably, the in-situ two-step etch processes is used to etch a nitride (i.e., silicon nitride) spacer layer formed over a semiconductor substrate having a plurality of gate structures. During the first stage, an interferometry endpoint (IEP) system is implemented to detect the etch endpoint during a main etch process. Subsequently, an overetch process is performed. Preferably, the main etch process removes an etch depth of the nitride spacer layer leaving a thin layer of nitride. Thereafter, the remaining thin layer of nitride is removed in an overetch process. In one example, the etch depth is measured by implementing a distance between adjacent maximum or minimum fringes of a particular endpoint detection wavelength. In one embodiment, the thin layer of nitride is removed in the overetch process implementing the timed-etch method. In another example, is the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com