Connection substrate, multi-layer wiring board using the connection substrate, substrate for semiconductor package, and methods for manufacturing them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

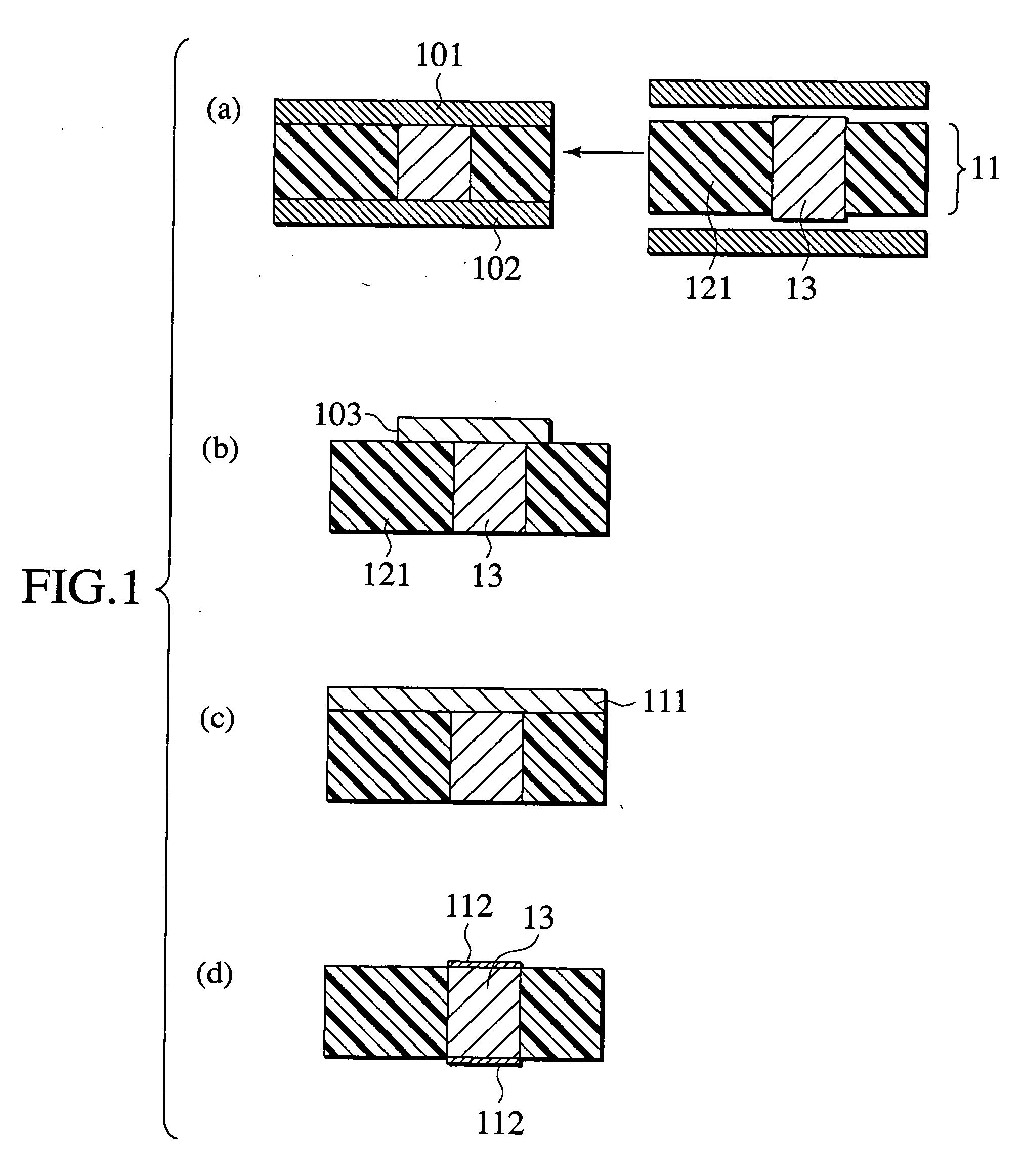

[0089] As shown in FIG. 4(a), a composite metallic layer 4 formed of 70 μm of first metallic layer 41 made of copper, 0.2 μm of third metallic layer 43 made of nickel and 35 μm of second metallic layer 42 made of copper was prepared. As shown in FIG. 4(b), a resist NCP225 or NIT225 (trade name manufactured by Nichigo-Morton Co., Ltd.) serving as an etching resist 44 was laminated on a surface of the first metallic layer 41 under conditions such as 110° C. of roll temperature and 0.6 m / min. of roll speed, formed under exposure conditions such as 80 mJ / cm2 of accumulated exposure amount, developed with sodium carbonate solution and subjected to post-exposure in order to ensure close contact of the resist. A rear surface is completely protected by laminating the etching resist 44 and exposing it on the same conditions as the above.

[0090] Then, an alkaline etching A process solution (trade name manufactured by Meltex Inc.) serving as an etchant which did not erode nickel was sprayed on...

example 2

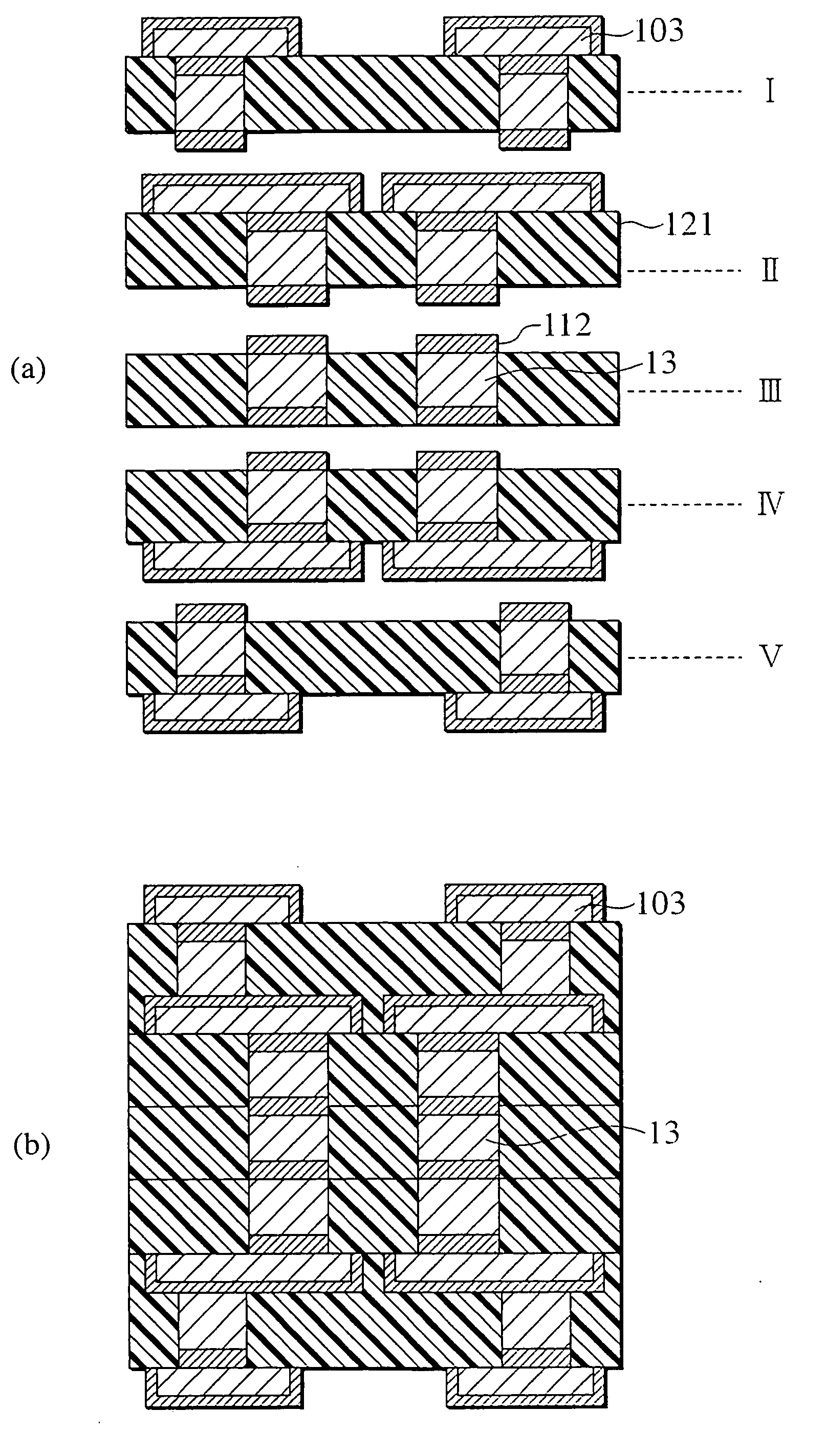

[0095] Electroless nickel plating, electroless palladium plating and electroless gold plating were successively performed upon surfaces of various connection boards obtained in Example 1. Then, the connection boards subjected to plating treatment were aligned as shown in FIG. 5(a) by guide pins and laminated at a time by pressing again at 333° C. In this way, a multi-layer wiring board shown in FIG. 5(b) was produced and its conductive connection by alloy of gold and gold was confirmed. At that time, an insulating resin composition between the connection boards was melted again and adhered with each other. When either of substitution type electroless tin plating and reduction type electroless tin plating was utilized for plating of connection boards, a multi-layer wiring board could be produced. Electroless nickel plating, electroless palladium plating and electroless gold plating were performed upon a connection board at an outermost layer and electroless tin plating was performed ...

example 3

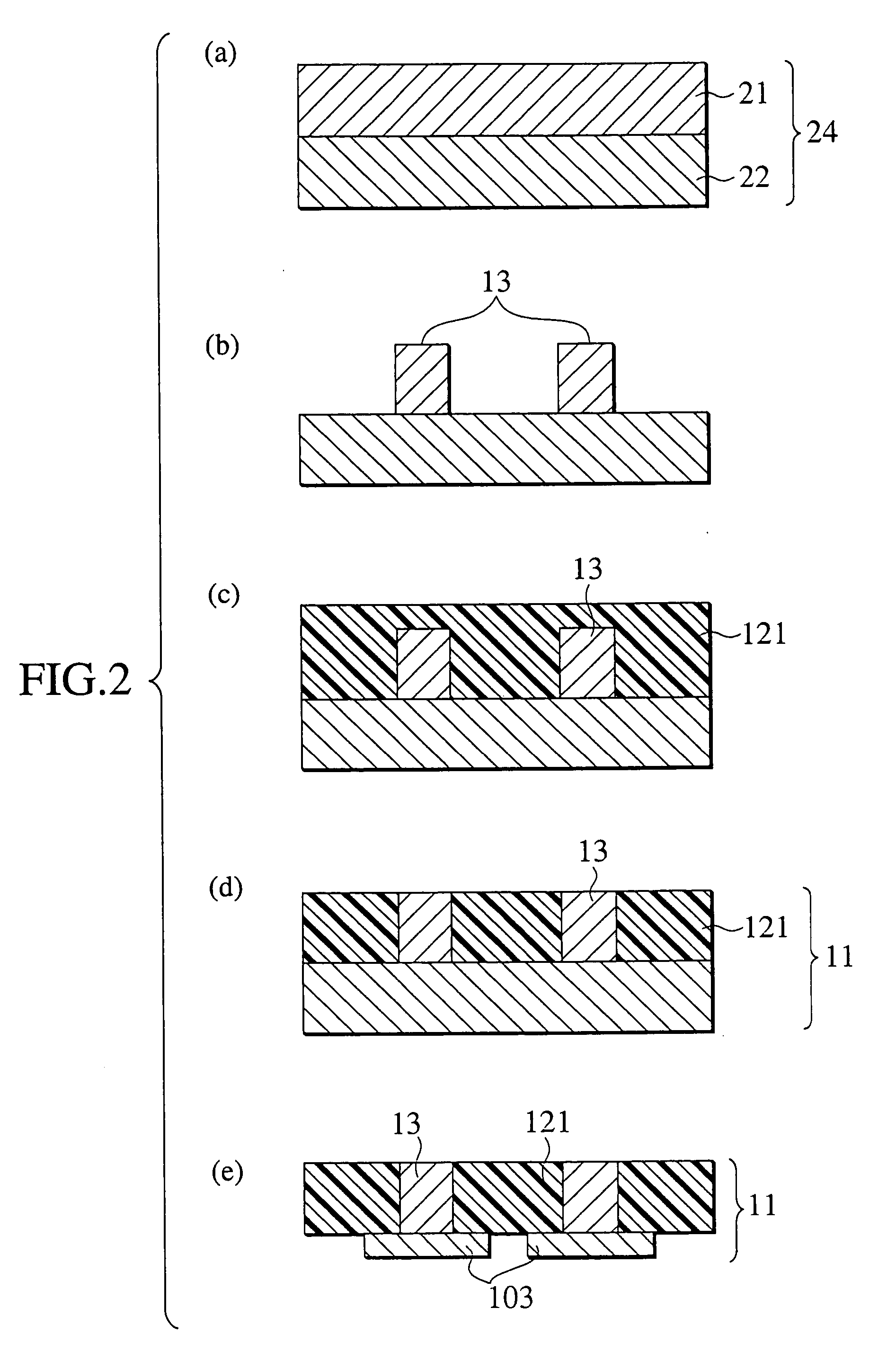

[0096] A substrate for semiconductor package and a semiconductor package were produced by using the connection board of FIG. 4(f) obtained in Example 1. Firstly, in order to form a fine circuit on a metallic layer 111 by etching, half etching for reducing a thickness of the metallic layer 111 to 18 μm was performed by spraying an etchant, prepared in such a manner that 100 g / L of aqueous hydrogen peroxide solution, sulfic acid and copper sulfate were mixed with each other and a resultant solution was adjusted so as to obtain 30 g / L of density of copper, on both sides of FIG. 6(a) at 35° C. of temperature of solution (FIG. 6(b)) At this time, since the thickness of ends of connection conductor is reduced, soldering balls are easily placed on such thinned end portions.

[0097] Then, as shown in FIG. 6(c), the conductor circuit 103 was formed by selectively removing the metallic layer 111 by etching. As shown in FIG. 6(d), electroless nickel plating, electroless palladium plating and el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com