Catalytic adsorbents for mercury removal from flue gas and methods of manufacture therefor

a technology of catalytic adsorbent and flue gas, which is applied in the direction of separation process, dispersed particle separation, chemistry apparatus and processes, etc., can solve the problems of mercury toxicity to humans and the environment, neurological damage in humans, wide spread neurological damage among the local population, etc., to promote the formation of mercury halide, increase the adsorbent capacity, and accelerate the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

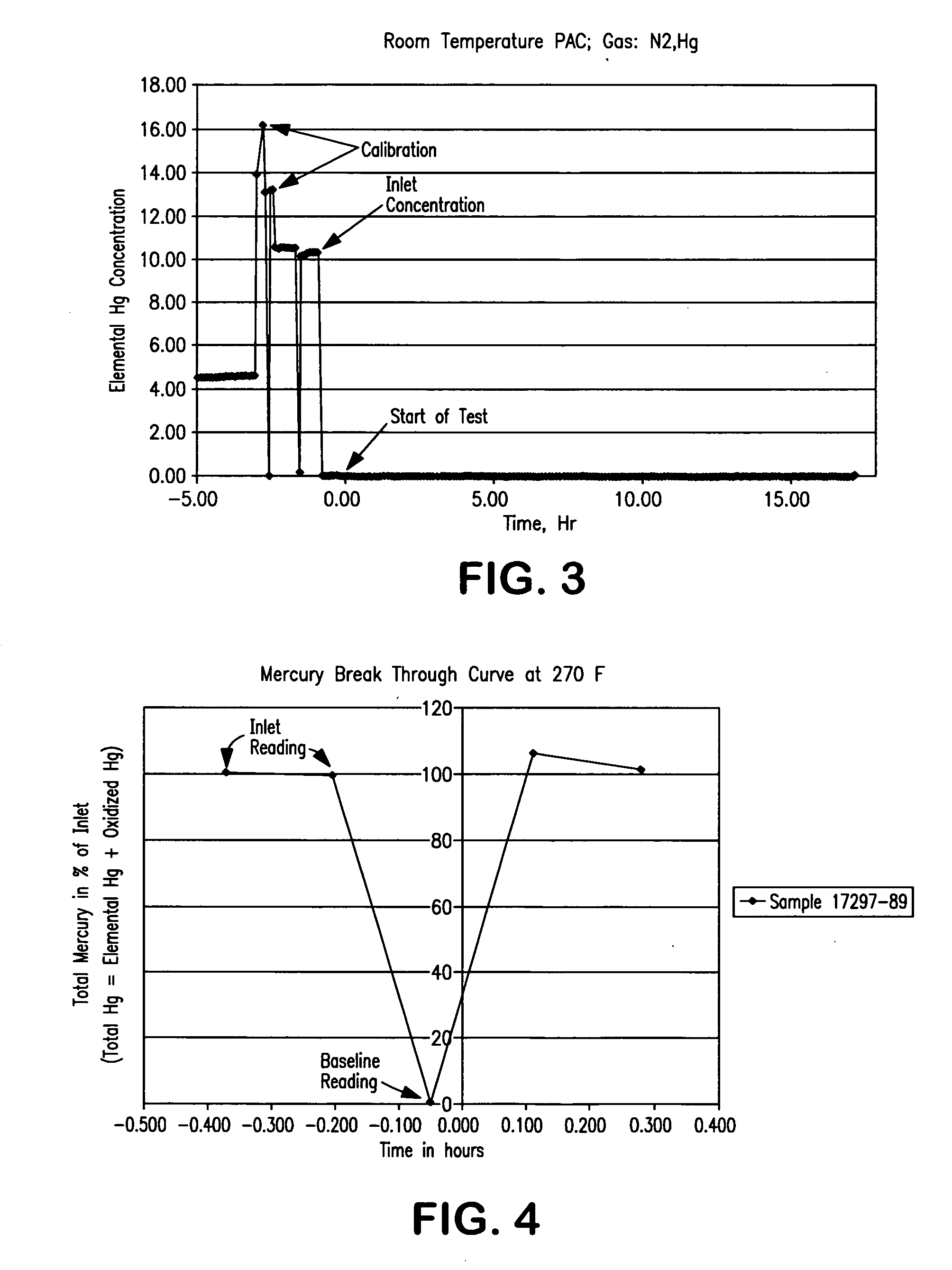

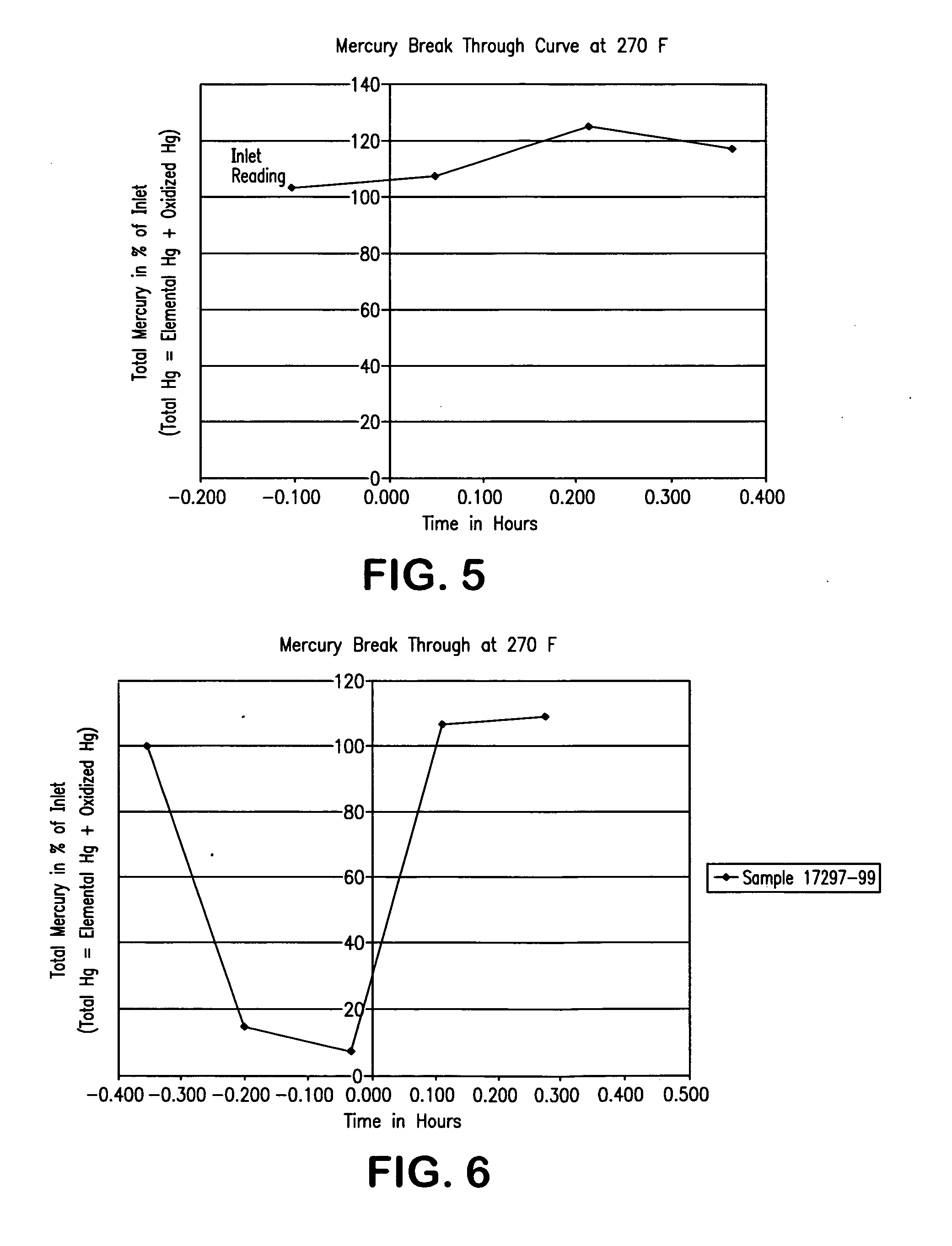

[0066] This example demonstrates that at room temperature, undoped PAC is a good adsorbent for elemental mercury and a promoter would appear to provide no additional benefit. At 270° F., however, physical adsorption is overwhelmed by kinetic energy and adsorption by undoped PAC and without a promoter was inadequate.

[0067] Fixed bed tests were conducted on four samples in a stream which contained nitrogen and about 13 μg / m3 of elemental mercury. The tests conditions and results are summarized in Table 1 and FIGS. 3-6. The undoped FGD carbon sample was tested at room temperature and achieved 100% mercury removal for more than 15 hours with no sign of mercury breakthrough. For samples tested at 270° F., all three types of activated carbon reached almost 100% breakthrough immediately (0% removal).

TABLE 1Test gasesSampleSampleTestcomposition andComments on TestSample #NametreatmentTempsequenceResultsFGDAs received 72 F.N2 + Hg100% Hg removal forcarbon15 hrs; no any signof breakthrough...

example 2

[0069] This example demonstrates how halide salts as a dopant alter the flue gas, mercury and carbon interaction so as to promote mercury adsorption from the flue gas stream. In this Example, thin fixed beds of PAC samples were exposed to different gas mixtures in sequence. All experiments started with nitrogen and mercury (about 13μ gm / cubic meter). Other components of the flue were added into the stream sequentially or in sequential combination toward a composition of synthetic flue gas, which is typified as: 6% O2, 12% CO2, 8% H2O, 1600 ppm SO2, 400 ppm NO, 20 ppm NO2, 50 ppm HCl, 12-14 μg / m3 Hg, with the balance being N2.

[0070] Two type of PAC (ashless and FGD) and three dopants (KBr, NaBr, and NaCl) were used in the experiments. Detail of the experiments are summarized in Table 2. The breakthrough curves are given in FIGS. 7-12.

TABLE 2Test gasesSampleSamplecomposition andComments onSample #NameDescriptionsequenceTest Results17297-99Ashless6 N HCl extraction1. N2 + Hg;Removed...

example 3

[0071] This example demonstrates that a physical adsorbent such as silica gel, doped with KBr, did not remove mercury from the flue gas.

[0072] The same thin fixed bed method as in Examples 1 and 2 was used in this Example. The details of sample preparation, test conditions and results are given in Table 3 and FIG. 13.

TABLE 3Test gasesCommentsSampleSamplecomposition andon TestSample #NameDescriptionsequenceResults17297-69KBrThe weight1. O2 6% + CO2The con-dopedratio of12% + H2O 8% + SO2centration ofsilicaKBr:Silica1600 ppm + NOHg reductiongelgel =400 ppm + HClwas less15:10050 ppm + NO2than 10%.20 ppm + Hg14 micro gram +N2 (fullsynthetic flue)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com