Semiconductor device

a technology semiconductors, which is applied in the direction of semiconductor devices, basic electric elements, electrical equipment, etc., can solve the problems the modification of p-i-n junction diodes has a long reverse recovery time at shutoff, and the drawbacks of not meeting the requirements (1) and (5) have not been solved so far, so as to achieve the effect of improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

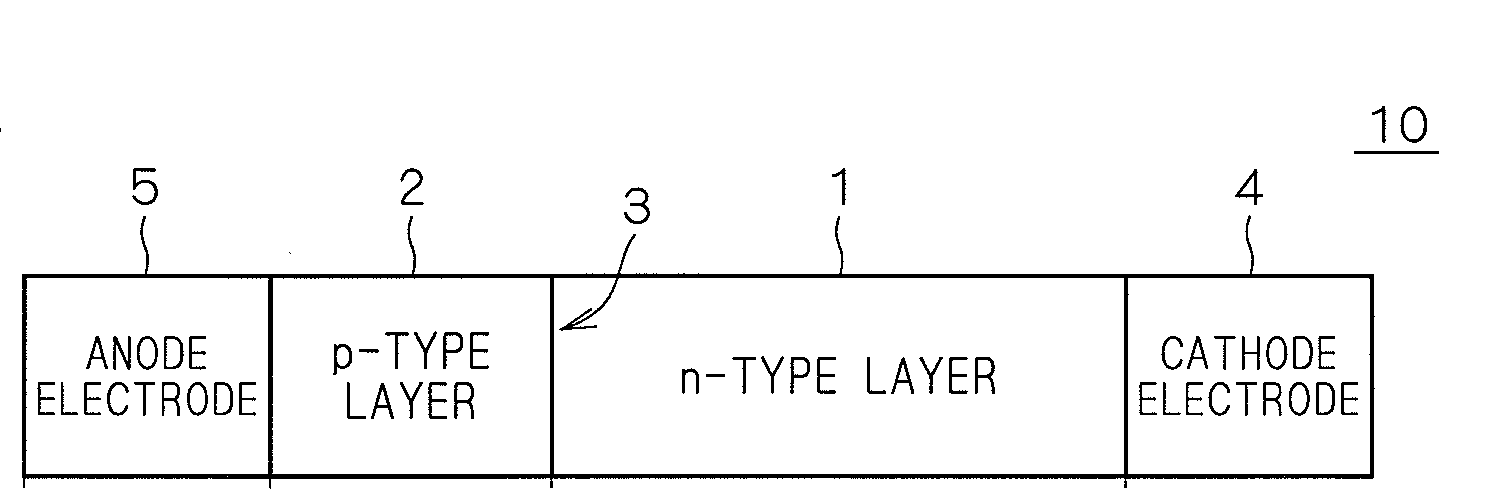

[0028]FIGS. 1A and 1B are diagrams for explaining the structure of a semiconductor device 10 according to a first preferred embodiment of the present invention. FIG. 1A schematically shows a sectional structure of the semiconductor device 10, and FIG. 1B shows the energy level of each layer constituting the semiconductor device 10. Each part in the respective drawings including FIGS. 1A and 1B is not always drawn at practical ratio. The structure of the semiconductor device 10 shown in FIG. 1A corresponds to the fundamental structure (conceptual structure) of various semiconductor devices by which the effects of the present invention can be achieved.

[0029]In the semiconductor device 10, an n-type layer 1 which is an n-type semiconductor layer and a p-type layer 2 which is a p-type semiconductor layer are joined at a junction 3, and a cathode electrode (cathode) 4 and an anode electrode (anode) 5 are provided next to the n-type layer 1 and p-type layer 2, respectively. In other words...

second preferred embodiment

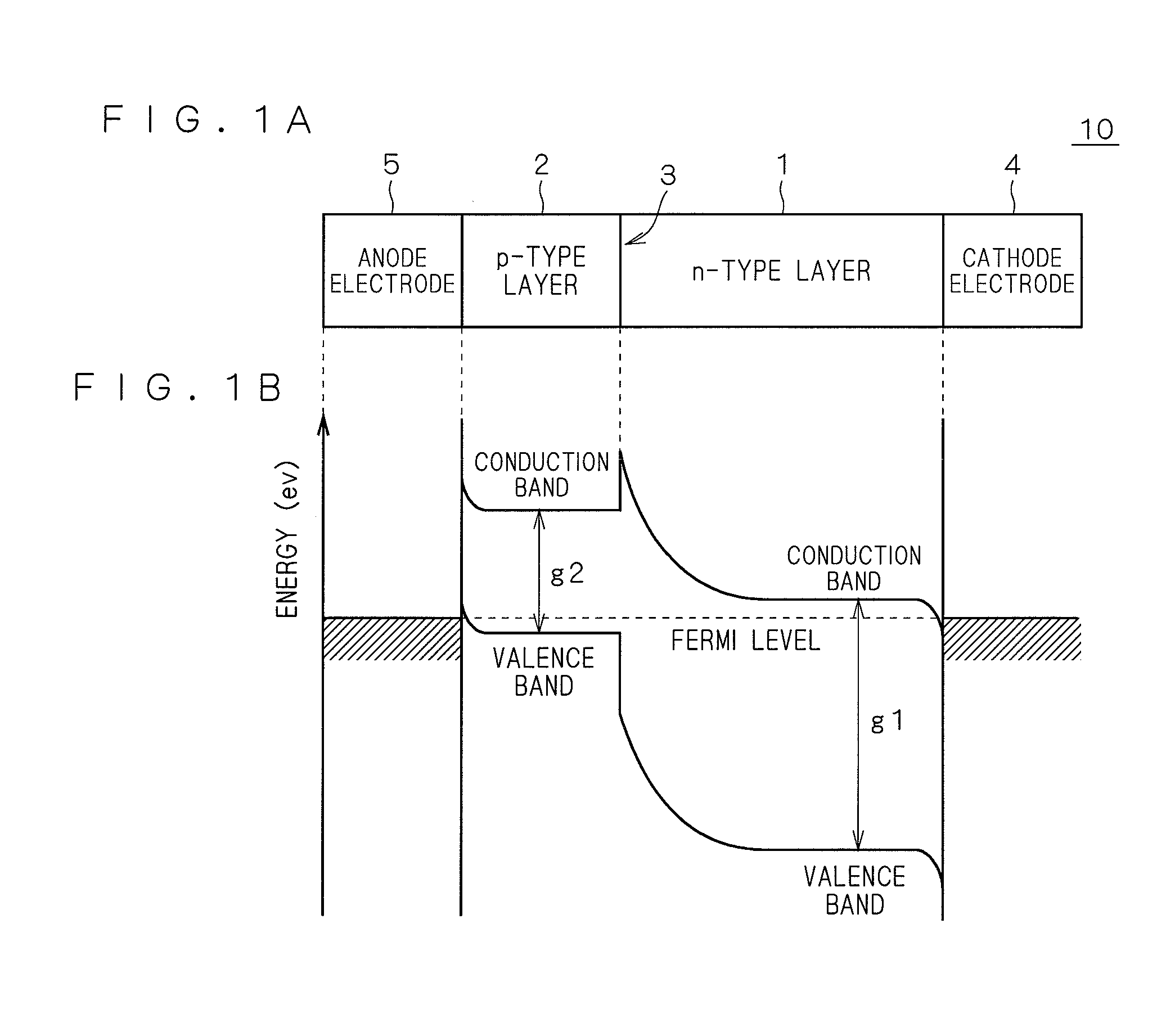

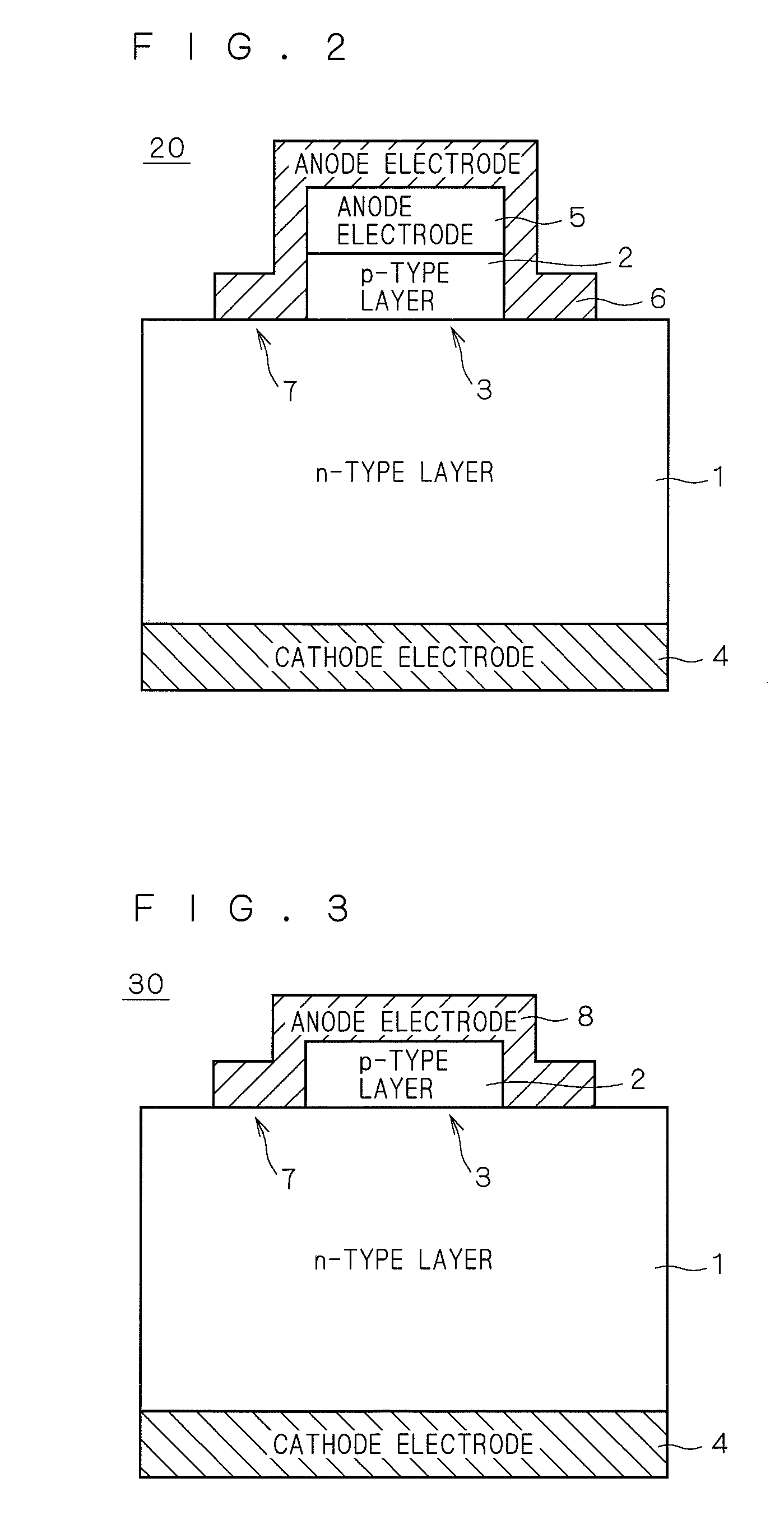

[0043]A more specific embodiment of a semiconductor device based on the conceptual structure described in the first preferred embodiment will now be described as a second preferred embodiment. FIG. 2 is a sectional view schematically showing the structure of a semiconductor device 20 according to the present embodiment. Among components of the semiconductor device 20 shown in FIG. 2, those achieving similar effects as those of the semiconductor device 10 are indicated by the same reference characters as in FIG. 1 and repeated explanation will be omitted.

[0044]The semiconductor device 20 shown in FIG. 2 features including a third electrode 6 not provided for the semiconductor device 10. The third electrode 6 is an electrode provided over the surfaces of the anode electrode 5 and n-type layer 1, and creates a Schottky junction with the n-type layer 1 at a junction 7 adjacent to the junction 3. In other words, the third electrode 6 covers the p-type layer 2 and anode electrode 5 deposi...

first example

[0049]In this example, a P—N junction vertical diode 110 which is one of specific embodiments of the semiconductor device 10 was prepared, and its properties were evaluated. FIG. 4A is a top view of the vertical diode 110, and FIG. 4B is a sectional view.

[0050]First, an n-type GaN substrate 1a having a thickness of 300 μm and an electron density of 1×1018 / cm3 was prepared. A GaN film 1b having an electron density of 1×1016 / cm3 was deposited thereon in a thickness of 5 μm by MOCVD to obtain the n-type layer 1.

[0051]Next, by ion implantation of Mg into part of the surface of the GaN film 1b and subsequent heat treatment for activating Mg, a field limiting ring 9 made of p-type GaN having a hole density of 1×1018 / cm3 was formed.

[0052]Subsequently, a Si layer doped with boron as an acceptor element of about 2×1020 / cm3 so as to have a hole density of 1×1019 / cm3 or higher was formed as the p-type layer 2 on the n-type layer 1 (specifically, on the GaN film 1b) in the form of a disc having...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com