Process including silo-chloro passivation for etching tungsten silicide overlying polysilicon

a technology of tungsten silicide and etching process, which is applied in the field ofplasma etching, can solve the problems of increasing difficulties, severe etching process requirements, and shrinkage, and achieve the effects of reducing the depth microloading, reducing the residence time of etching, and increasing the selectivity of silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

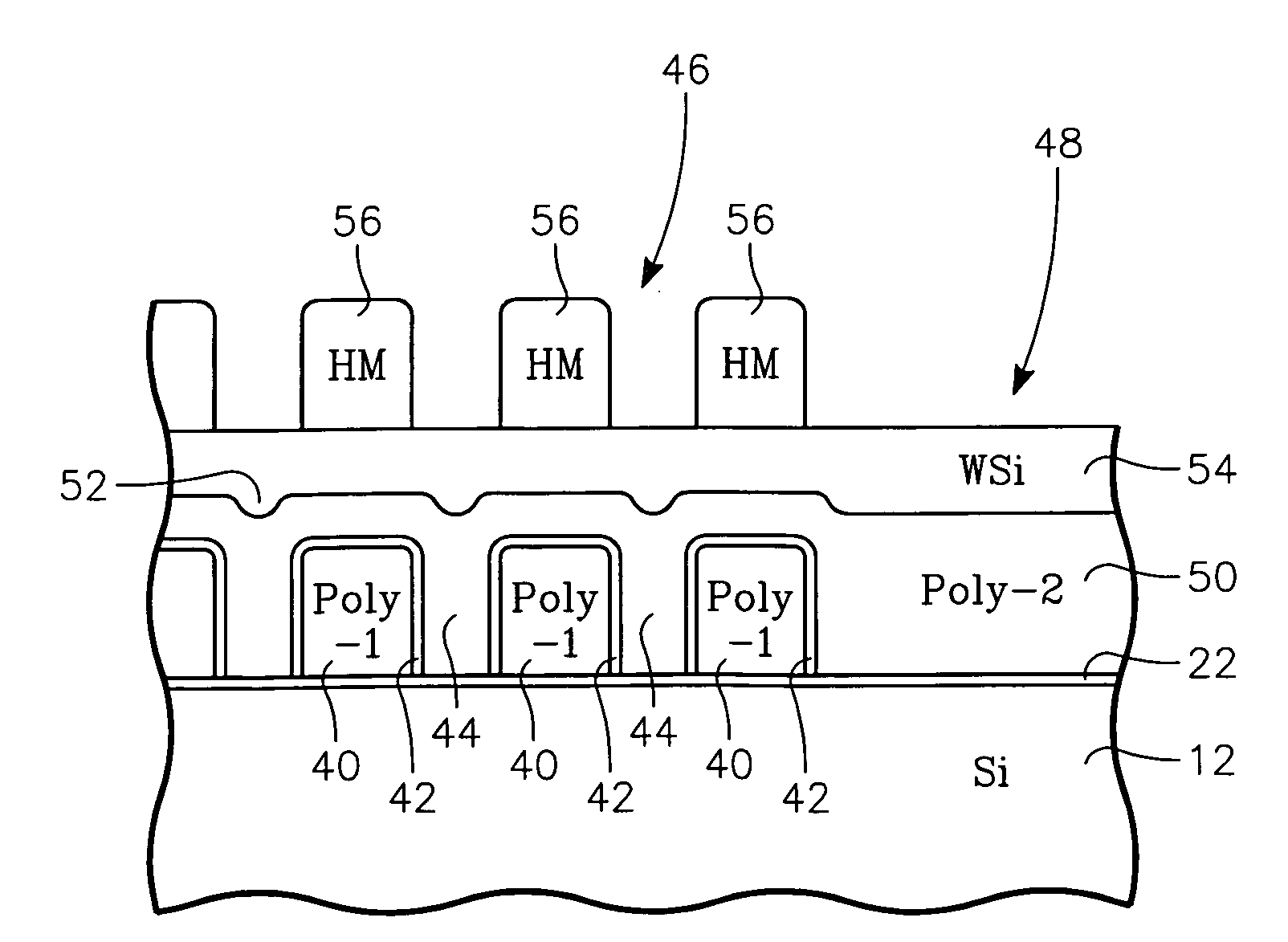

[0024]With reference to FIG. 3, we have observed several difficulties in etching the WSi layer 54 through the hard mask 56. In advanced designs, the thicknesses of all the layers need to minimized to reduce the overall size of the memory cell so there is little margin for errors and non-uniformity in etching depths. The depths of the troughs 52 have been observed to be up to 70% of the thickness of the WSi layer 54 in more planar areas. Accordingly, once a main etch (ME) has etched through the WSi layer 54 in the planar areas, a long over etch (OE) is required to clear out the WSi residue from the troughs 52. The over etch may extend for 75 to 100% of the time of the main etch. The long over etch requires good selectivity of the WSi etch to silicon in the second polysilicon layer 50. The etching profiles need to be maintained as vertical as possible, both in the WSi layer 54 and in the portion of the polysilicon consumed in the overetch. The distinction between the dense and iso are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com