Composition of water-soluble metalworking fluid using distillation residue generated in production of biodiesel

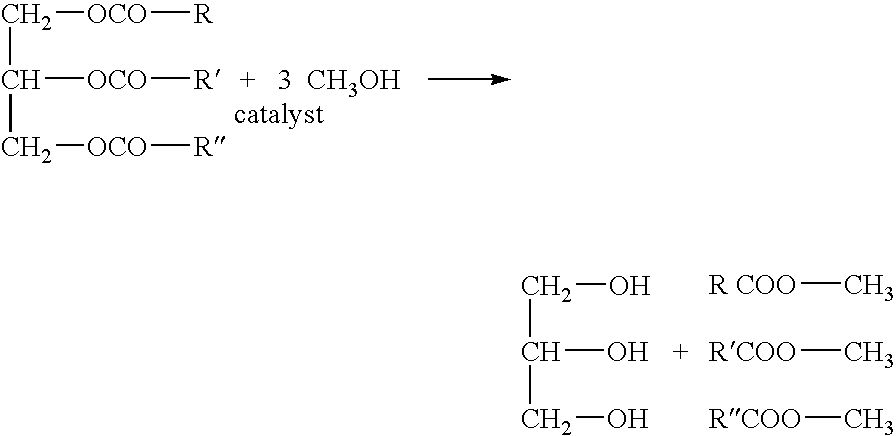

a technology of biodiesel and distillation residues, applied in the direction of additives, lubricant compositions, base materials, etc., can solve the problems of biodiesel having several problems in substituting, less wettability and lubrication, and engine breakage, and achieve the effect of less harmful to the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 1

[0032]Water-soluble metalworking fluids were manufactured from a distillation residue generated in production of biodiesel, ion exchange water, a lubricating additive 1 (soybean oil, canola oil, palm oil, trimethylolpropane trioleate, pentaerythritol tetraoleate, or ricinoleic acid condensate), a surfactant, a metal corrosion inhibitor, a rust inhibitor, a pH booster, a defoamer and a preservative.

[0033]Contents of the water and the biodiesel distillation residue depend on application ranges of the product. As the product has a higher content of water, the diluted solution is clearer, while as the product has a higher content of the distillation residue, the diluted solution is milky white and has better lubrication performance.

TABLE 1Composition of Water-soluble Metalworking FluidNameS-1S-2S-3S-4S-5Biodiesel distillation residue51.367.837.361.091.0Ion exchange water17.55.028.09.00Lubricating additive 14.51.56.03.50.7Surfactant15.015.617.016.36.3pH booster8.06.58.05.51.5Metal corros...

exemplary embodiment 2

[0034]Water-soluble metalworking fluids were produced from a distillation residue generated in production of biodiesel, a lubricating additive 2 (petroleum-based hydrocarbon, methyl ester of soybean oil or canola oil, soybean oil, canola oil, or palm oil), a surfactant, a metal corrosion inhibitor, a rust inhibitor, a pH booster, a defoamer and a preservative.

TABLE 2Composition of Water-soluble Metalworking FluidNameS-6S-7S-8S-9S-10Biodiesel distillation residue43.044.825.340.852.0Ion exchange water13.610.028.516.50Lubricating additive 218.019.518.312.016.0Surfactant15.815.615.715.520.3pH booster6.56.58.011.59.0Metal corrosion inhibitor0.30.20.50.50.1Rust inhibitor2.22.22.02.02.0Preservative0.51.01.51.00.5Defoamer0.10.20.20.20.1

exemplary embodiment 3

[0035]Water-soluble metalworking fluids were produced from a distillation residue generated in production of biodiesel, a lubricating additive 3 (petroleum-based hydrocarbon, methyl ester of soybean oil, canola oil or palm oil, trimethylolpropane trioleate, pentaerythritol tetraoleate or ricinoleic acid condensate), a surfactant, a metal corrosion inhibitor, a rust inhibitor, a pH booster, a defoamer and a preservative.

TABLE 3Composition of Water-soluble Metalworking FluidNameS-11S-12S-13S-14S-15Biodiesel distillation residue23.056.825.339.850.0Ion exchange water18.610.032.017.55.0Lubricating additive 330.87.014.115.016.0Surfactant16.915.213.913.516.3pH booster6.57.010.510.59.0Metal corrosion inhibitor0.30.30.50.50.5Rust inhibitor2.22.52.02.02.0Preservative1.51.01.51.01.0Defoamer0.20.20.20.20.2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com