Blast resistant and blast directing container and assemblies

a technology of container and assembly, which is applied in the direction of mechanical equipment, transportation and packaging, and discharging methods of containers, etc., can solve the problems of dangerous projectiles, failure of containers, and door openings providing a significant weak point of containers, etc., and achieves the effect of reducing production costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

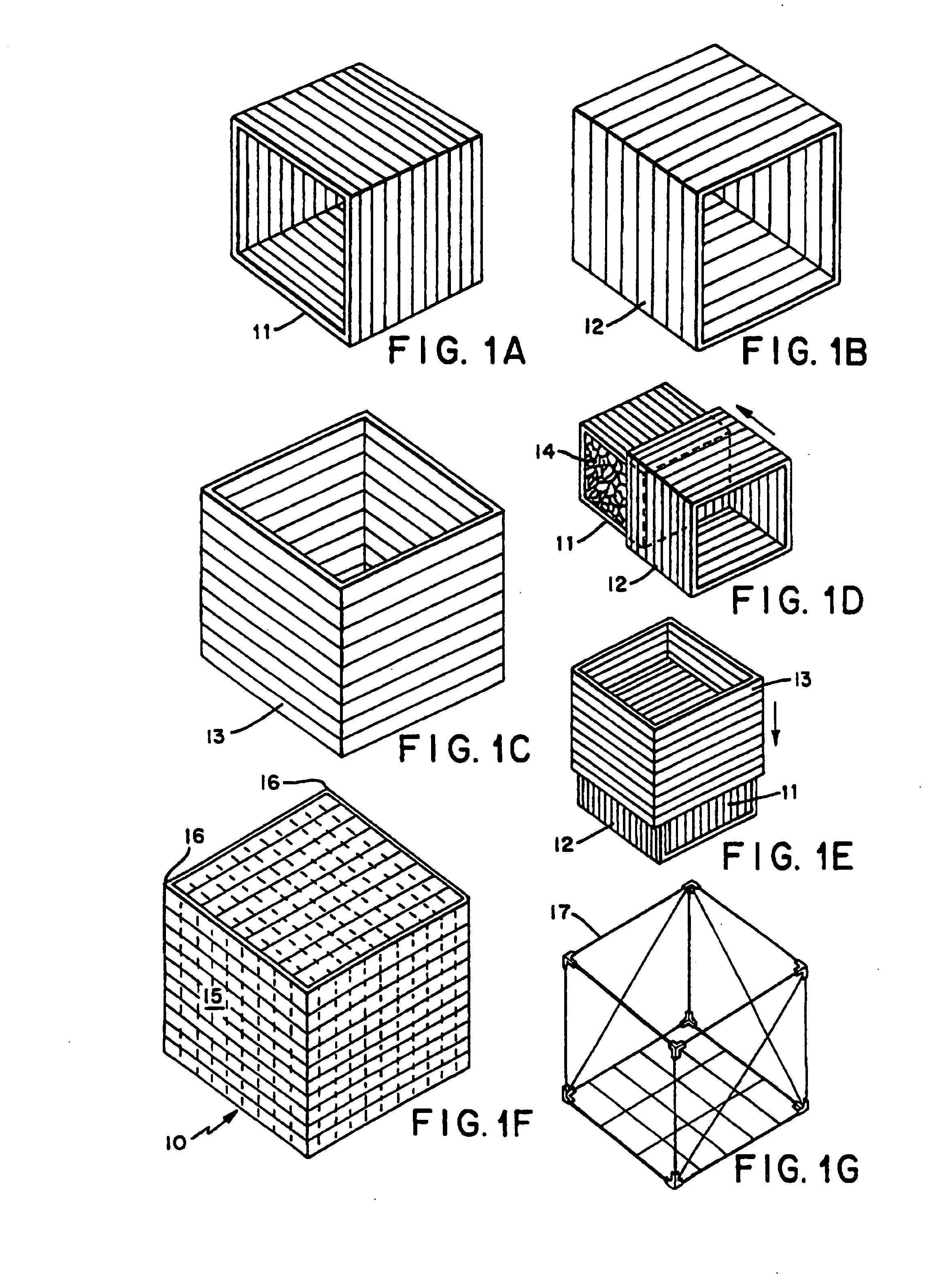

[0158]A SPECTRA SHIELD® PCR composite roll, commercially available from AlliedSignal, Inc., was cut into four 15 inch wide strips, each approximately 330 inches in length. The SPECTRA SHIELD® PCR composite contained 80 weight percent SPECTRA® 1000 extended chain polyethylene fiber (nominal tenacity of about 35 g / d, tensile modulus of about 1150 g / d, and elongation-to-break of about 3.4%, also available from AlliedSignal, Inc.) in a 20 weight percent resin matrix of polystyrene-polyisoprene-polystyrene block copolymer, available from Shell Co. under the trade name KRATON® D1107. The SPECTRA fibers were arranged in the composite in a 0° / 90° configuration. Each strip was wrapped in successive layers around a square cross-sectional mandrel having a side length of 15 inches to form a band having 22 wraps of SPECTRA SHIELD. The wrapping of each successive strip was started at the point where the prior strip ended, with the identical fiber configuration and under sufficient tension (about ...

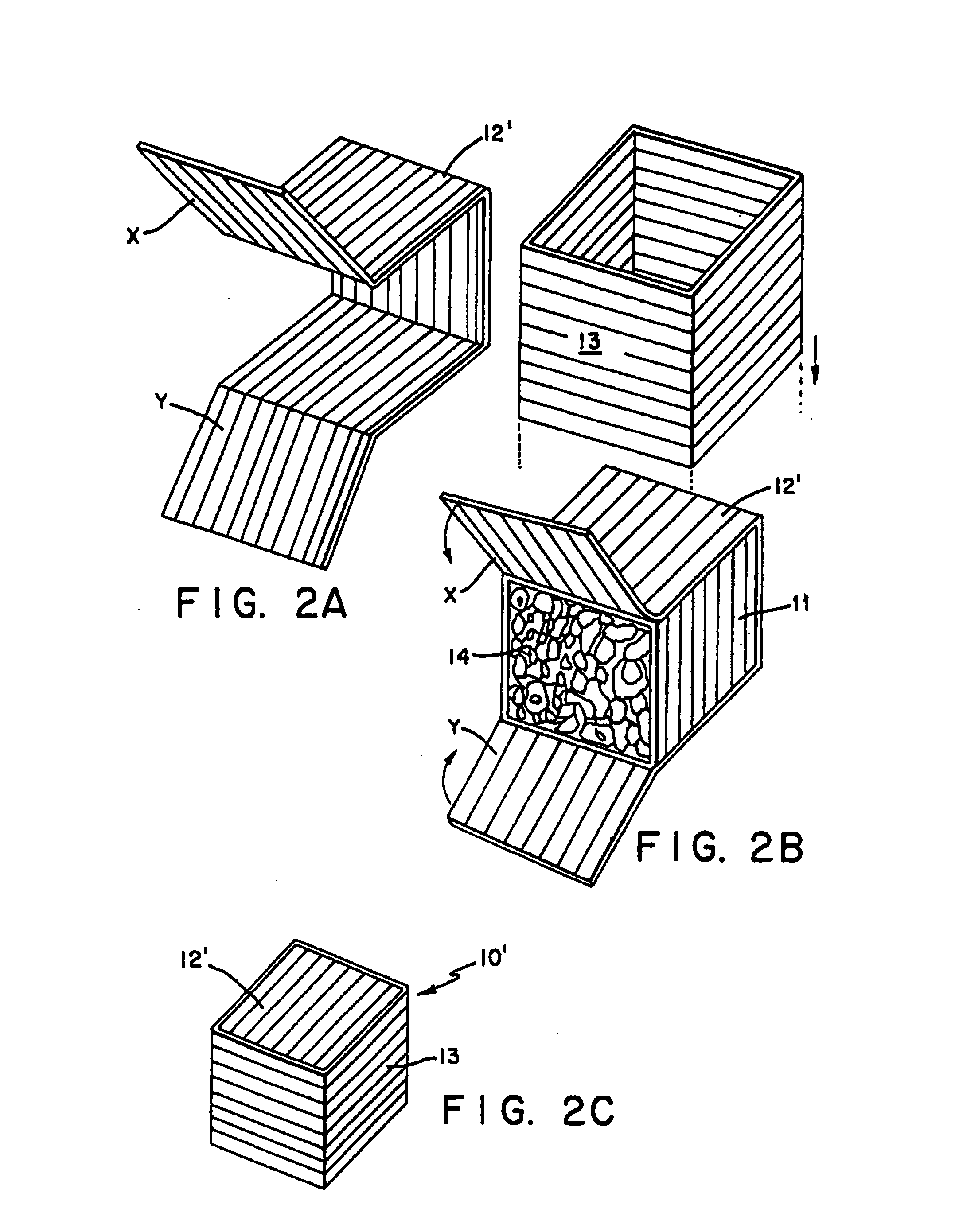

example 3

[0167]A box was constructed in the same manner as Box 2 of Example 2 above, with the following changes. The mandrel was modified so that the edges were round, having a radius of ⅝ inch. The areal density of the bands was one-half that of Box 2. The flap width on Band 1, the inner band, was increased to 6 inches. Band was reinforced to control deformation and the rate of escape of gases from the explosion. This reinforcement consisted of first wrapping the mandrel in two complete wraps of 15 inch wide S-2 glass cloth (Style 6781, areal density 0.309 kg / m2, manufactured by Clark Schwebel). This glass cloth was impregnated with EPON 828 epoxy resin, commercially available from the Shell Co., by using 8 pph Millamine, a cycloaliphatic diamine, available from Milliken Chemical Co., as a room temperature curing agent. The glass / resin ratio was 48 / 52 by weight. The SPECTRA SHIELD composite strips for Band 1 were then wound on top of the glass fabric, which became an integral part of Band 1...

example 4

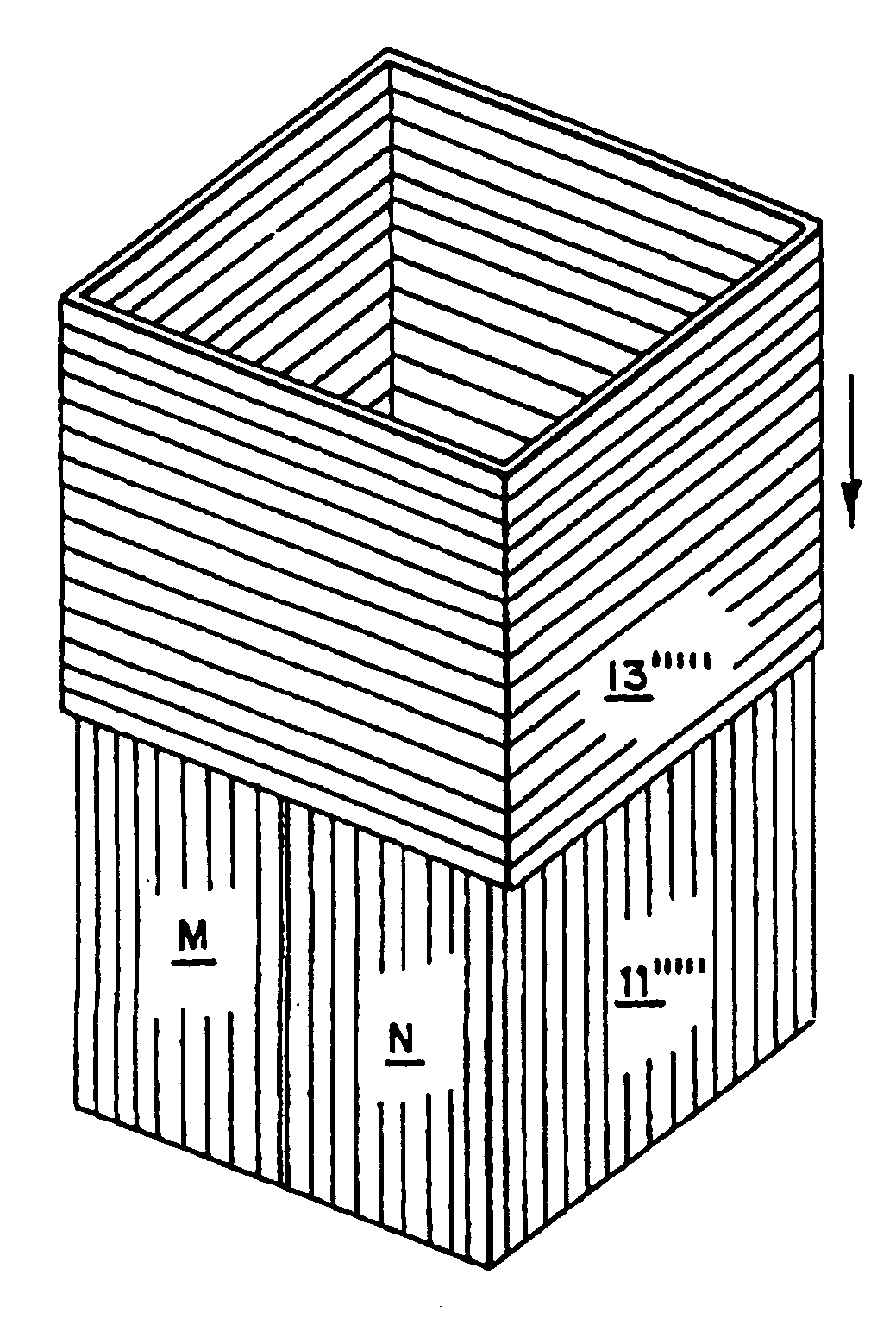

[0170]A box was constructed like Box 2 of Example 2 with the following modifications. In Band 1, the first half of the composite strip length was 21 inches wide while the second half was 15 inches wide. This permitted eight flaps to be created, four per side of the band, each 3 inches by 15 inches and having an areal density 4.75 kg / m2. Band 1 consisted of 10 SPECTRA SHIELD composite wraps and had an areal density of 9.5 kg / m2. An 0.125 inch wide aluminum plate was placed around Band 1. Band 2 was formed by wrapping strips that were 17 inches wide around the spacer. A second spacer of 0.125 inch width was placed around Band 2 and Band 3 was formed by wrapping strips that were 18 inches wide. The three bands were removed from the mandrel and from the spacers. In each band, about 50 weight percent of the fiber was continuous and oriented in the hoop direction.

[0171]Four 14 inch square fiberglass plates, commercially available from 3M Corporation as Scotch Ply Type 1002, and having an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com