Tunable Diffraction Grating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

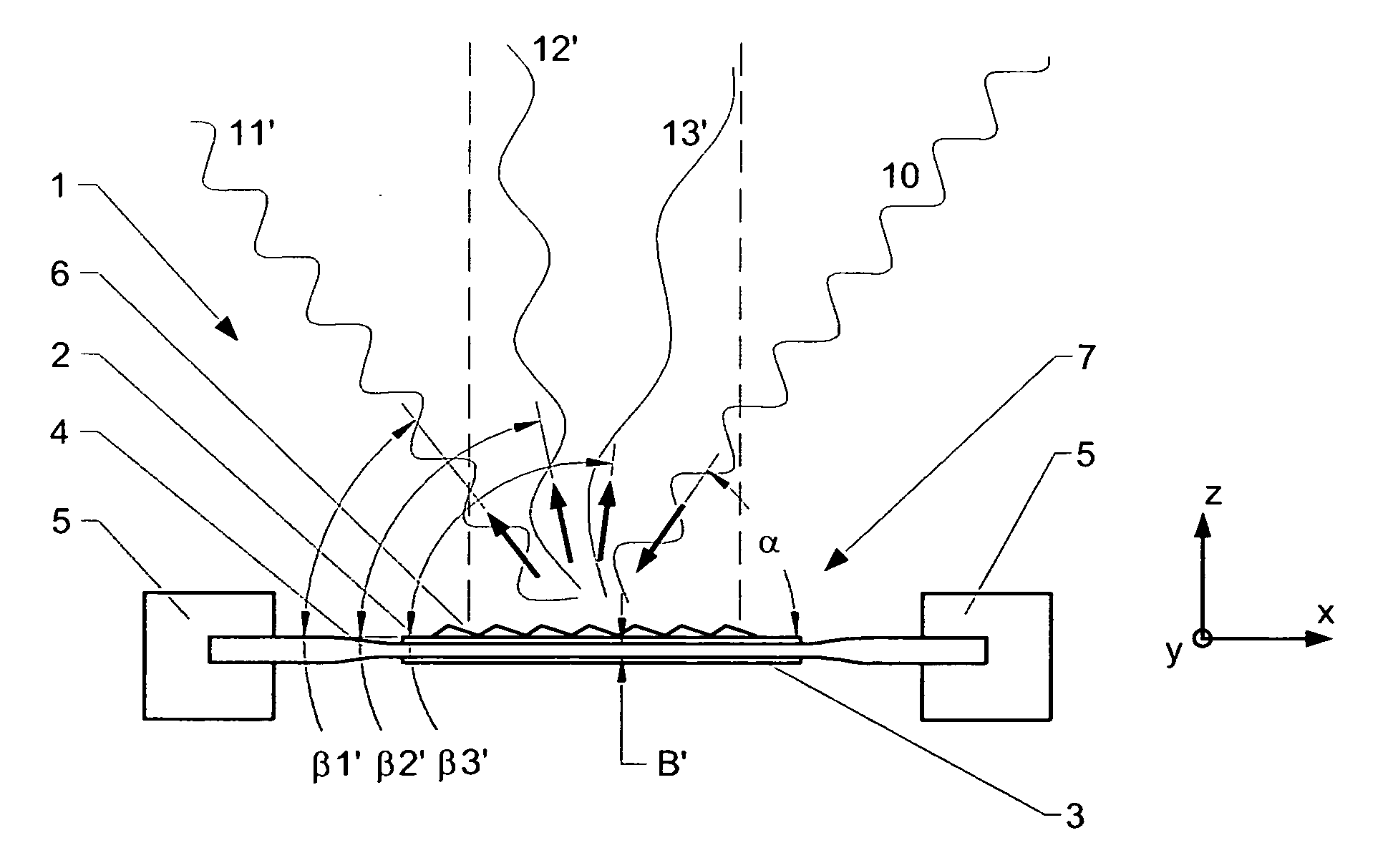

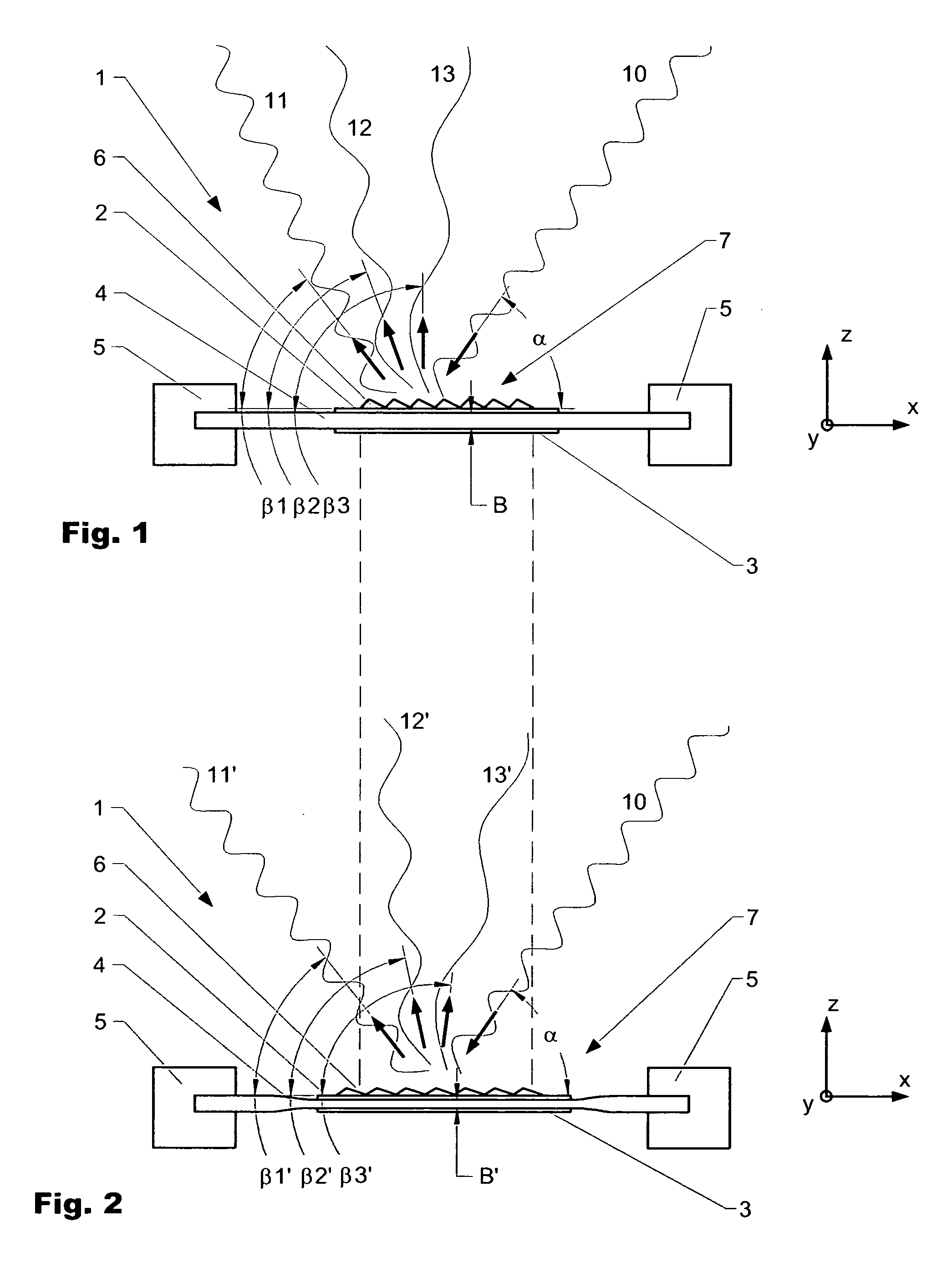

[0061]FIG. 1 schematically shows a tunable diffraction grating 1 according to the present invention in an undeformed state (V=0). The diffraction grating comprises an upper and a lower electrode 2, 3 which encompass an membrane like intermediate layer 4 made out of a deformable material, preferably an elastomeric material. The intermediate layer 4 is held in position by a support 5, if appropriate in a prestretched manner. At least the upper electrode 3 is also made out of a deformable material such that it can deform in lateral direction along with the intermediate layer 4. The intermediate layer 4 and at least the upper electrode 2 are mechanically coupled to each other such that a secondary lateral deformation in xy-plane of the intermediate layer 4 causes a lateral deformation of the upper electrode 2 in the same direction.

[0062]When a voltage (V≠0) is applied to the dielectric elastomer actuator the upper and the lower electrodes 2, 3 attract each other due to electrostatic for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com