Thermosetting resin composition and prepreg and laminate both made with the same.

a technology of thermosetting resin and composition, which is applied in the field of thermosetting resin composition, can solve the problems of short heat resistance, low yield of bismaleimide compounds and aminophenols, and short heat resistance, and achieve the effect of reducing the tangen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

Production of a Maleimide Compound (B-1)

[0069]A reactor having a volume of 2 liter which was equipped with a thermometer, a stirring device and a moisture determining device equipped with a reflux condenser and which could be heated and cooled was charged with 358.0 g of bis(4-maleimidephenyl)methane, 54.5 g of m-aminophenol and 412.5 g of propylene glycol monomethyl ether ((maleimide group equivalent) / (equivalent in terms of a —NH2 group)=4.0), and they were reacted for 5 hours while refluxing to obtain a solution of a maleimide compound (B-1).

production example 2

Production of a Maleimide Compound (B-2)

[0070]A reactor having a volume of 2 liter which was equipped with a thermometer, a stirring device and a moisture determining device equipped with a reflux condenser and which could be heated and cooled was charged with 358.0 g of bis(4-maleimidephenyl)methane, 54.5 g of p-aminophenol and 412.5 g of propylene glycol monomethyl ether ((maleimide group equivalent) / (equivalent in terms of a —NH2 group)=4.0), and they were reacted for 5 hours while refluxing to obtain a solution of a maleimide compound (B-2).

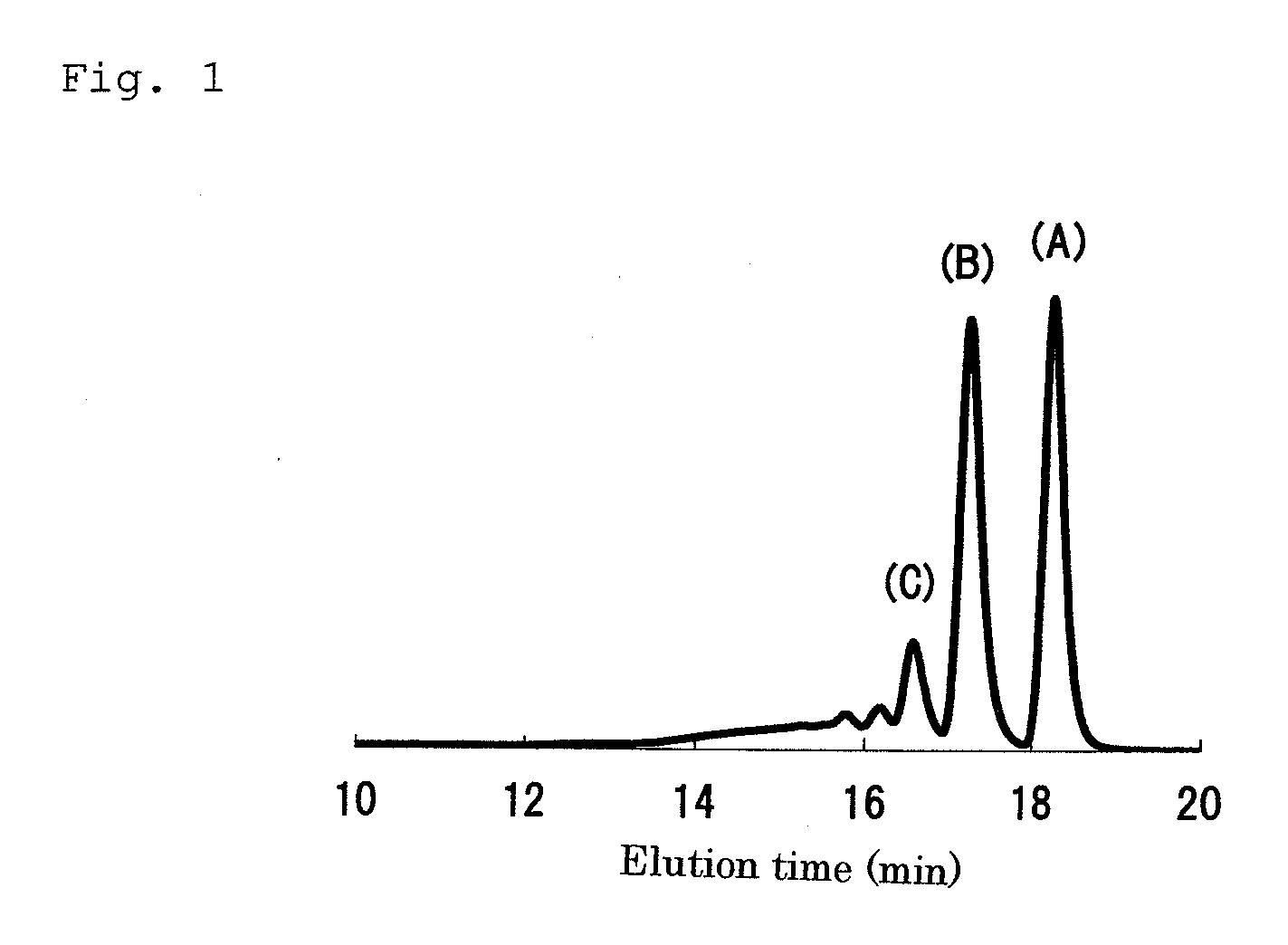

[0071]The above solution was analyzed by GPC (gel permeation chromatography, eluent: tetrahydrofuran), and a result thereof is shown in FIG. 1.

[0072]According to FIG. 1, a peak of p-aminophenol appearing in the vicinity of an elution time of about 19 minutes was not observed, and peaks (B) and (C) originating in the addition products were confirmed. In this case, the peak (A) shows bis(4-maleimidephenyl)methane which is the synthetic raw mate...

production example 3

Production of a Maleimide Compound (B-3)

[0073]A reactor having a volume of 2 liter which was equipped with a thermometer, a stirring device and a moisture determining device equipped with a reflux condenser and which could be heated and cooled was charged with 358.0 g of bis(4-maleimidephenyl)methane, 27.4 g of p-aminobenzoic acid and 385.4 g of N,N-dimethylacetamide ((maleimide group equivalent) / (equivalent in terms of a —NH2 group)=10.0), and they were reacted at 140° C. for 5 hours to obtain a solution of a maleimide compound (B-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com