Target, method for producing the same, memory, and method for producing the same

a technology of target and memory, which is applied in the direction of transportation and packaging, vacuum evaporation coating, coating, etc., can solve the problems of difficult simultaneous dissolution of constituent elements, difficult to form a target by dissolution methods, etc., and achieve the effect of less danger of ignition, less risk of ignition, and reduced number of cathodes in the film formation apparatus for forming an ionization layer of memory devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental examples

3. Experimental Examples

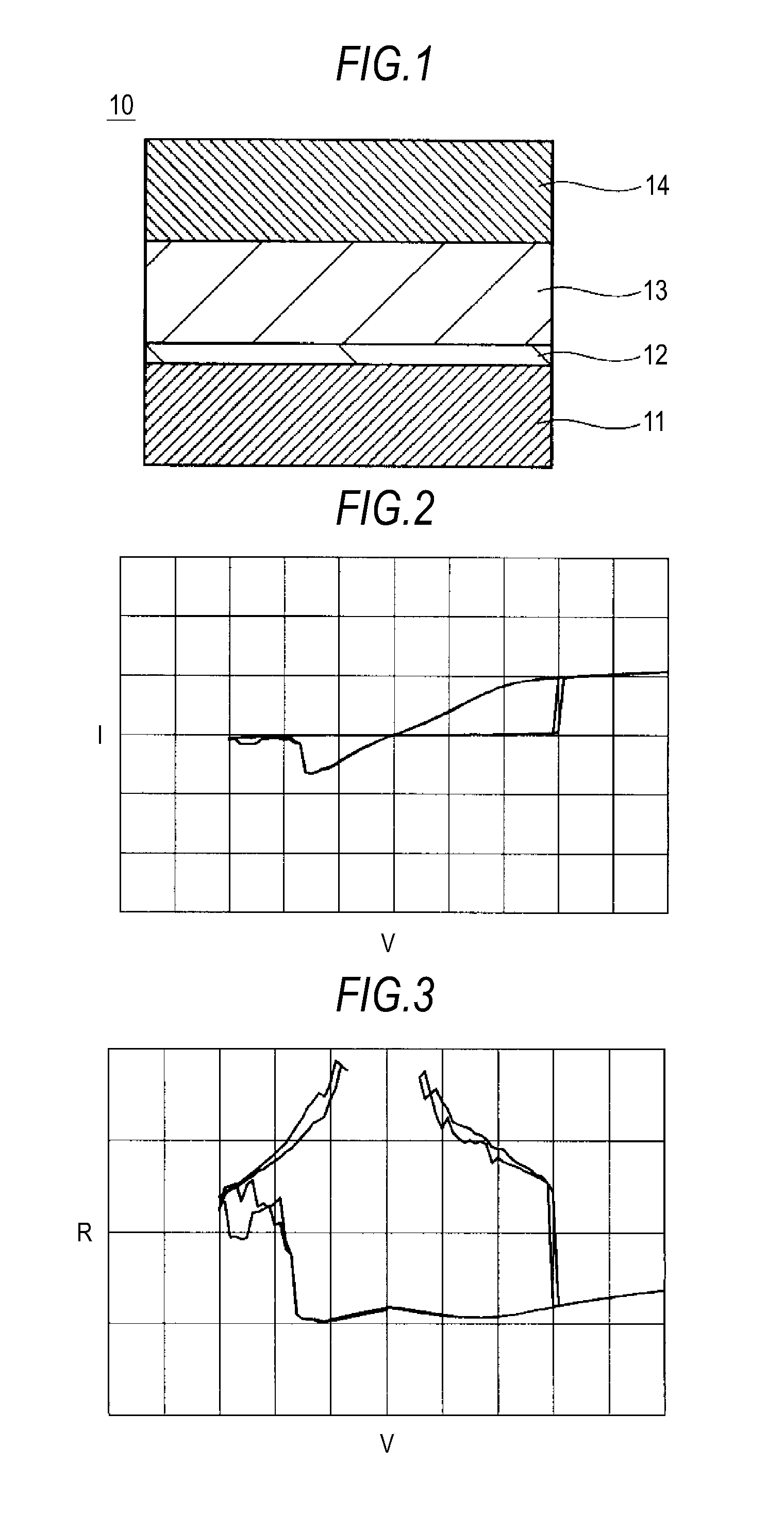

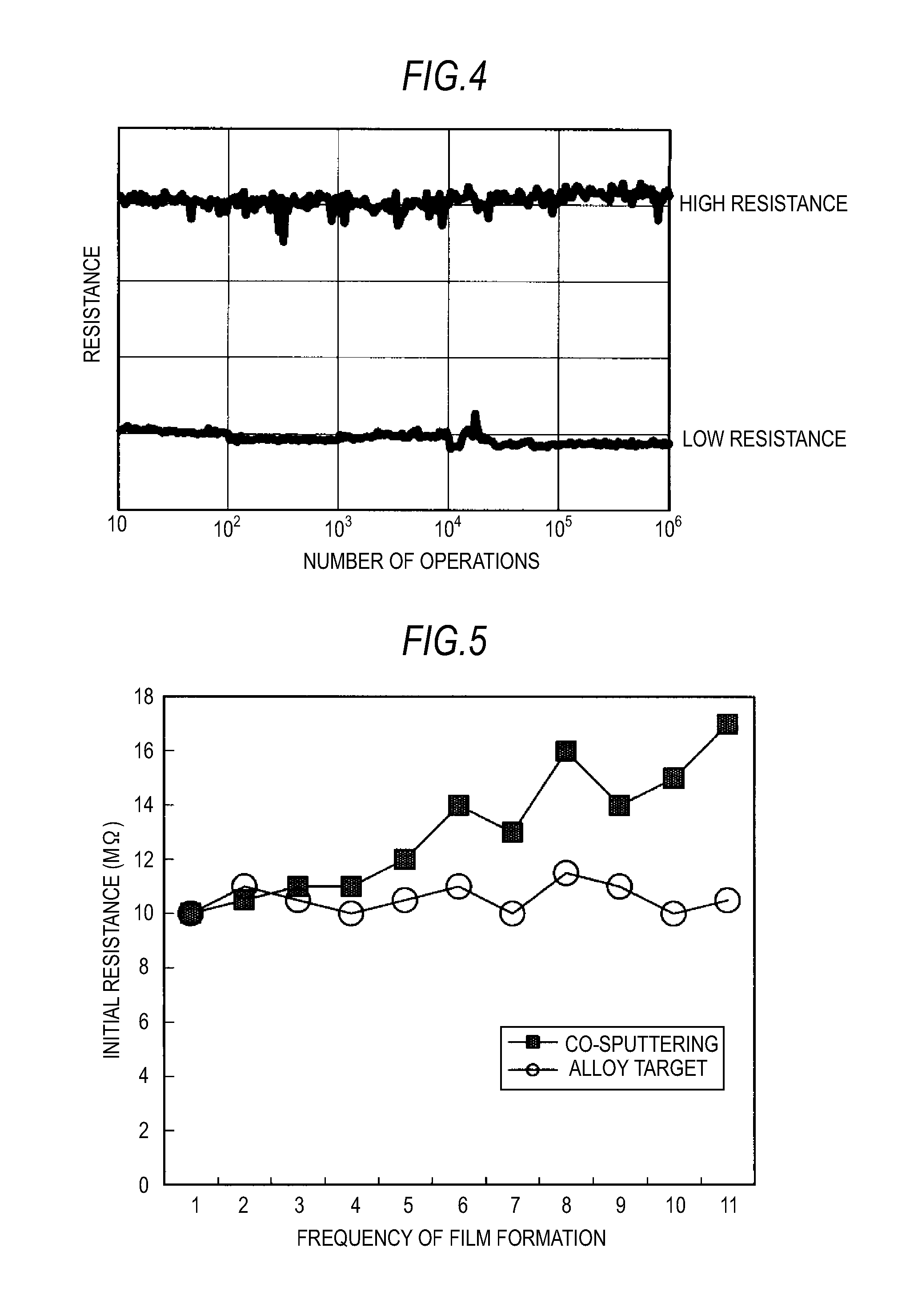

[0136]A target was actually produced, and a memory including memory devices was produced using the target.

[0137]With respect to the memory, the characteristics of its memory devices were examined.

example 1

[0138]First, using a 1-mm3 Zr scrap as a Zr raw material of the group of refractory metal elements M1, 1-cm3 Al pellets and a 3-cm2 Cu thin plat as raw materials of the group of elements M2 were dissolved in a high-frequency melting furnace to prepare an AlCuZr alloy ingot.

[0139]Subsequently, the alloy ingot was pulverized in an attritor to prepare an alloy powder with a particle diameter of 106 Ωm or less.

[0140]Subsequently, the alloy powder was mixed with a Te powder with a particle diameter of 75 μm or less and a Ge power with a particle diameter of 32 to 106 μm, and the mixture was sintered to give an AlCuGeTeZr target base material.

[0141]The target base material was then cut into a disc-like piece with a thickness of 5 mm and a diameter of 300 mm to give a target.

[0142]The prepared target was adhered to the backing plate of a sputtering apparatus using In wax.

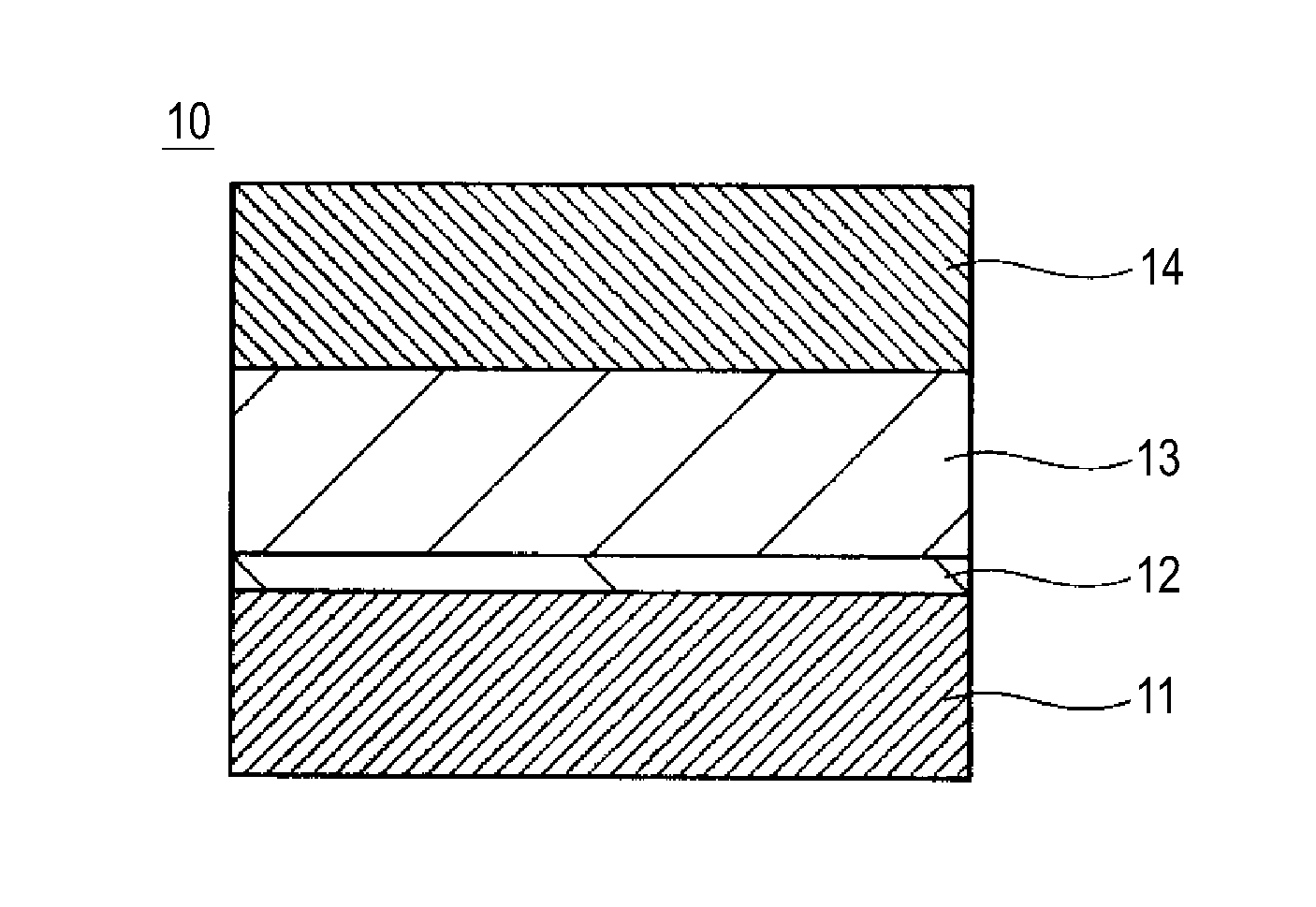

[0143]Subsequently, a Gd oxide film with a thickness of 2 nm was formed as a high resistance layer 12 on a CMOS circuit ...

example 2

[0154]Using a 1-mm3 Zr scrap as a Zr raw material of the group of refractory metal elements M1, an Al powder as an Al raw material of the group of elements M2 was mixed and dissolved in a high-frequency melting furnace to prepare an AlZr alloy ingot. The prepared alloy ingot was pulverized to give an alloy powder.

[0155]Subsequently, Ge, Cu, and Te raw materials were dissolved in a high-frequency melting furnace to prepare an alloy ingot, which was then pulverized to give an alloy powder.

[0156]These two kinds of alloy powders were then mixed at a desired composition ratio, and sintered to give an AlCuGeTeZr target base material.

[0157]The target base material was then cut into a disc-like piece with a thickness of 5 mm and a diameter of 300 mm to give a target.

[0158]Then, in the same manner as in Example 1, a memory cell array having a large number of memory devices 10 was formed on a wafer to give a sample of the memory of Example 2.

[0159]The characteristics of the memory of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com