Functional cotton spray composition, method for producing the same, and building material using the same

a technology of cotton spray and composition, which is applied in the direction of lignin material coating, antifouling/underwater paint, heat storage plants, etc., can solve the problems of insufficient derivation of spray coating materials, inability to regenerate, and harmful to human bodies, so as to reduce the change in indoor air temperature, drastically improve heat insulation performance, and cool environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

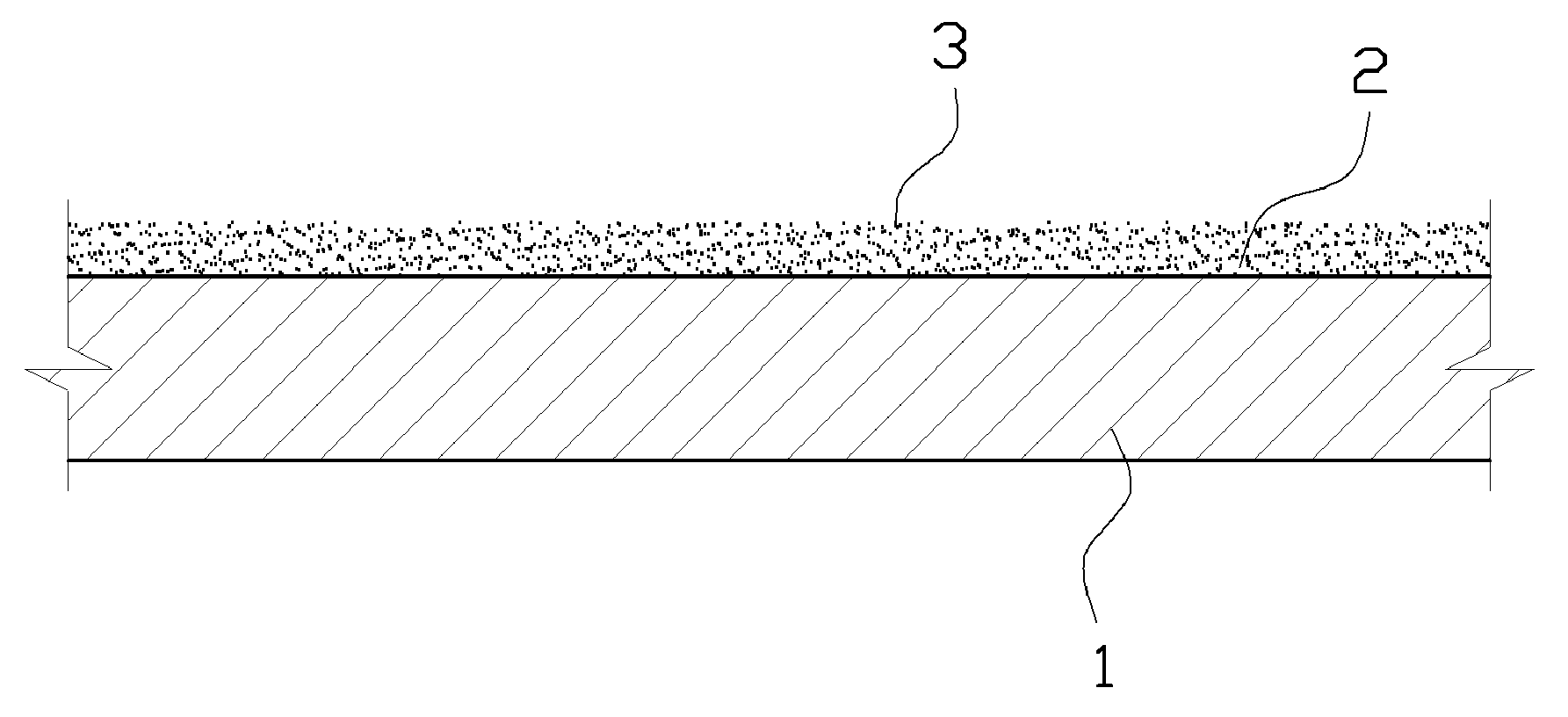

[0115]Put into a kneader are: 100 parts by weight of cotton fibers having a length of 3 mm or less; 0.5 to 5 parts by weight of a microcapsule type phase change material having organic and inorganic coating layers, which is coated with a polymeric material as an organic material and then with an inorganic material; 0.5 to 1 parts by weight of a titanium dioxide photoactive catalyst; 0.5 to 2 parts by weight of at least one natural pigment selected from the group consisting of a pine needle powder, a green tea powder, a mugwort powder, an indigo plant powder, a gardenia powder, a charcoal powder and a yellow soil powder; 0.5 to 5 parts by weight of polyethylene oxide as a dispersant for preventing entanglement of the cotton fibers; 5 to 20 parts by weight of carboxyl methyl cellulose as a viscosity improver for urging the cotton fibers to be bonded together; 10 to 20 parts by weight of ammonium polyphosphate as an organic flame retardant; 5 parts by weight of pentaerythritol as a fla...

example 2

[0117]A cotton spray composition was produced in the same manner as in Example 1 except that 0.5 to 2 parts by weight of at least one substance selected from the group consisting of jasmine fragrance oil, green tea fragrance oil, lemon fragrance oil, baby powder fragrance oil and lavender fragrance oil is further added.

[0118]It was able to confirm that the fragrance oil thus added emits subtle perfume within an indoor area to which the cotton spray composition is applied. This makes it possible to create a pleasant living environment.

example 3

[0119]A cotton spray composition was produced in the same manner as in Example 1 except that 10 to 20 parts by weight of Portland cement as an inorganic binding and curing agent is further added and mixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com