Electrical Discharge Coating Method and Green Compact Electrode Used Therein

a technology of electric discharge and green compact electrode, which is applied in the direction of solventing apparatus, manufacturing tools, transportation and packaging, etc., can solve the problems of poor high-temperature strength, poor wear resistance and corrosion resistance, poor corrosion resistance of aluminum materials, etc., and achieves the effect of improving the moldability of green compact electrode, reducing the conductivity of coating surface, and high melting poin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

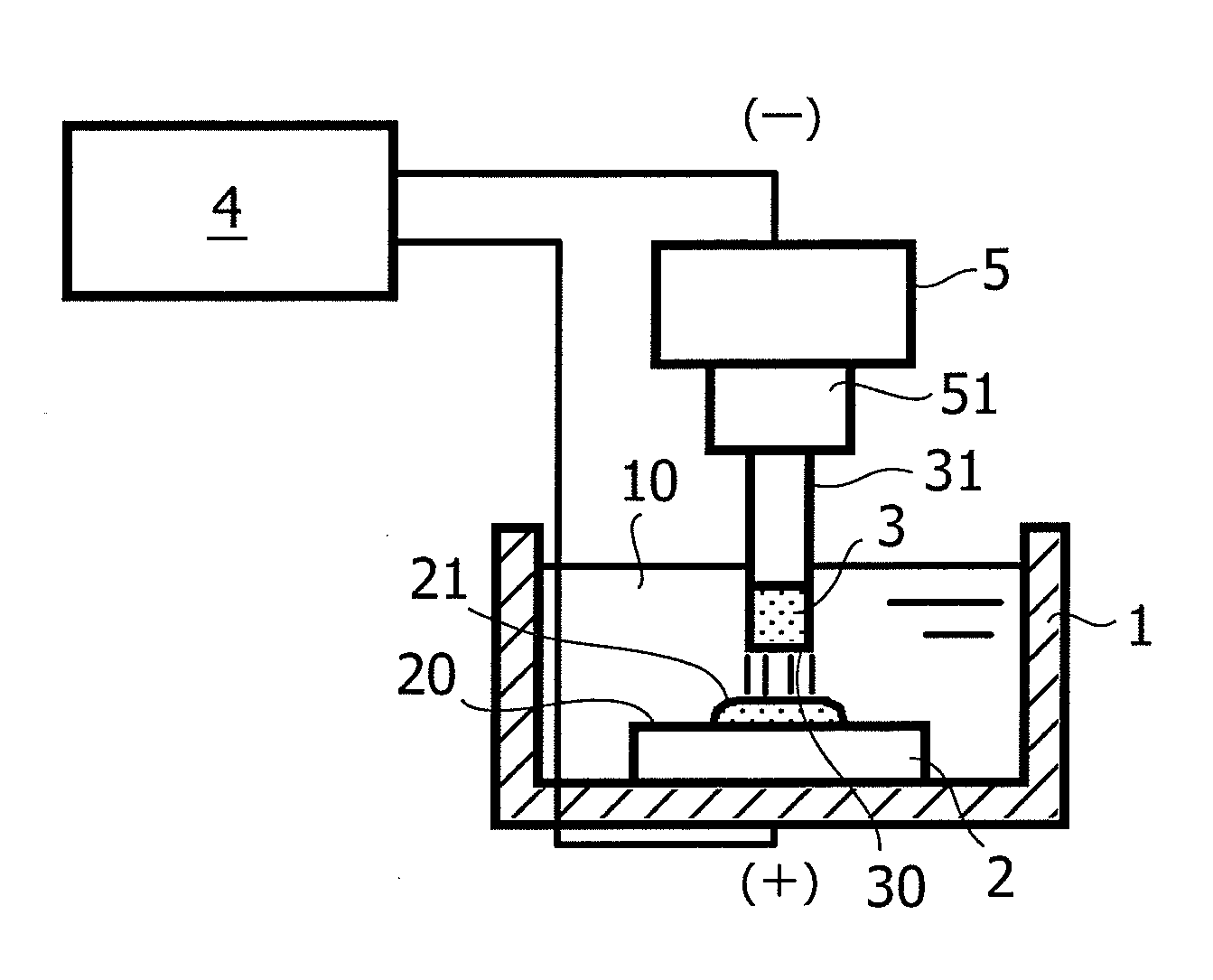

Method used

Image

Examples

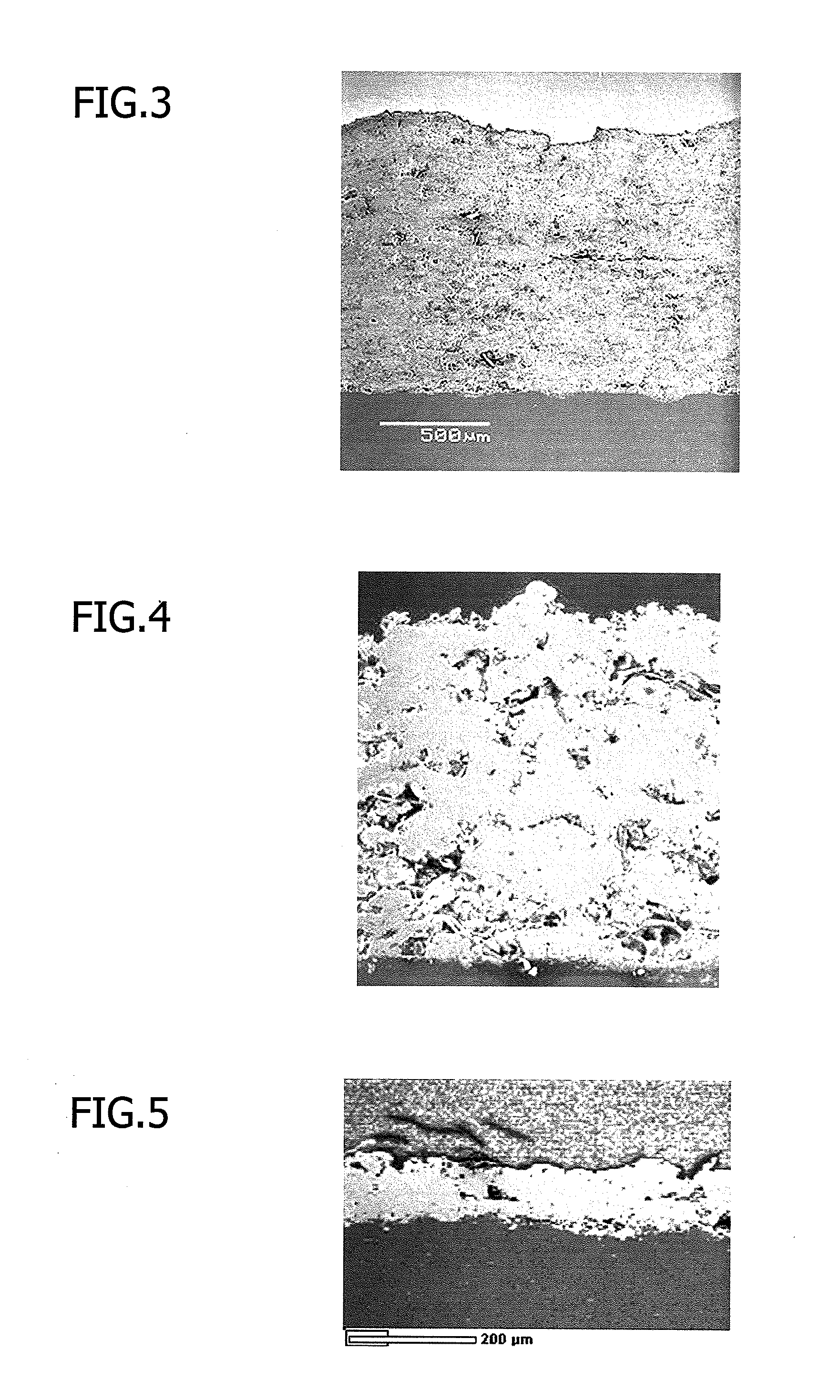

examples

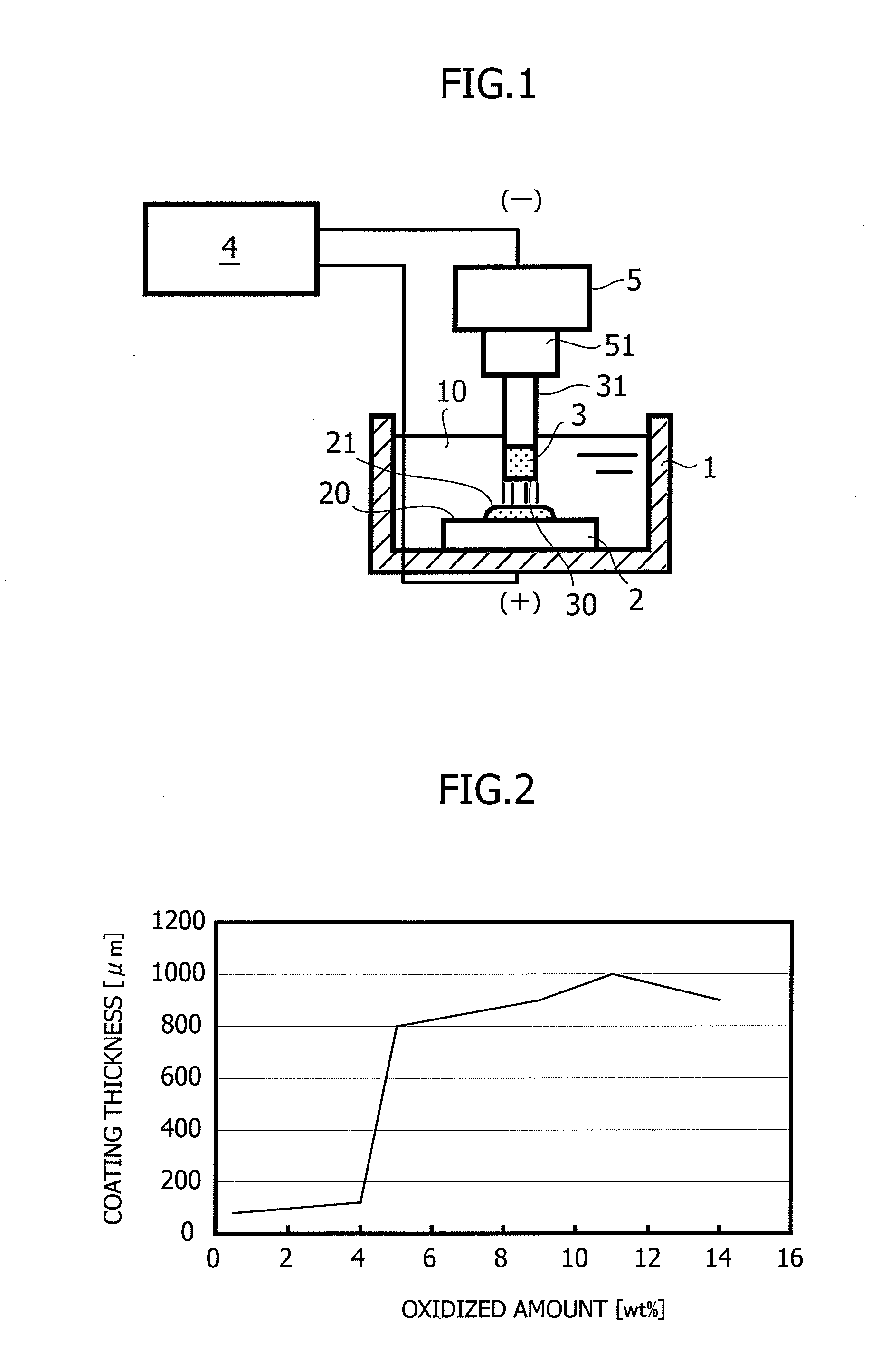

[0065]To test the above-described influence on coating thickness of the oxide layer on the metal powder surface, the following experiments were carried out. Specifically, an electrical discharge coating treatment was performed on surfaces of an aluminum material, a magnesium material, and a titanium material while changing only the amount of oxidation of metal powder but without changing the formation conditions of a green compact electrode and the electrical discharge conditions thereof. Then, changes in coating thickness after the treatment were examined.

[0066]The experiment on the surface of the aluminum material was carried out as follows. A molybdenum powder having an average particle diameter of 2 μm was used as the metal powder. Columnar green compacts each having a diameter of 13.8 mm were prepared at a molding pressure of 400 MPa while changing the oxidized amount of the metal powder in a range from 3 to 14% by weight through an oxidation treatment performed under atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com