Image processing method, and image processing apparatus

a technology of image processing and image processing apparatus, applied in the direction of duplicating/marking methods, printing, etc., can solve the problems of high pressure, deformation of thermoplastic recording medium, and deformation of flexible recording medium, so as to ensure the effect of repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0289]Hereinafter, the present invention will be described in more detail with reference to Examples, which however shall not be construed as limiting the scope of the present invention.

[0290]A thermally reversible recording medium capable of reversibly changing in color tone depending on a change in temperature was produced in the following manner.

—Support—

[0291]As a support, a white turbid polyester film of 125 μm in thickness (TETRON FILM U2L98W, produced by TEIJIN DUPONT FILMS JAPAN LTD.) was used.

—Formation First Oxygen Barrier Layer—

[0292]A urethane-based adhesive (produced by Toyo-Morton Ltd., TM-567) (5 parts by mass), isocyanate (produced by Toyo-Morton Ltd., CAT-RT-37) (0.5 parts by mass), and ethyl acetate (5 parts by mass) were mixed and substantially stirred to prepare an oxygen barrier layer coating liquid.

[0293]Next, the oxygen barrier layer coating liquid was applied onto a silica-deposited PET film (produced by Mitsubishi Plastics Inc., TECHBARRIER HX, oxygen permea...

production example 2

Production of Thermoreversible Recording Medium

[0304]A thermoreversible recording medium of Production Example 2 was produced in the same manner as in Production Example 1, except that a first thermoreversible recording layer, a photothermal conversion layer and a second thermoreversible recording layer were produced according to the following procedures.

—Formation of Thermoreversible Recording Layer Containing Photothermal Conversion Material—

[0305]A reversible developer represented by the above Structural Formula (1) (5 parts by mass), a color-erasing accelerator represented by the above Structural Formula (2) (0.5 parts by mass), a color-erasing accelerator represented by the above Structural Formula (3) (0.5 parts by mass), a 50% by mass acrylpolyol solution (hydroxyl group value: 200 mgKOH / g) (8 parts by mass) and methylethylketone (80 parts by mass) were pulverized and dispersed in a ball mill until the average particle diameter became about 1 μm.

[0306]Next, in a dispersion li...

example 1

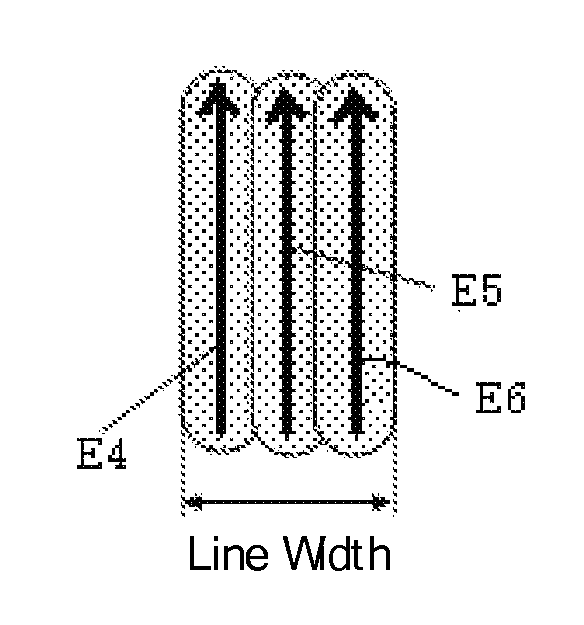

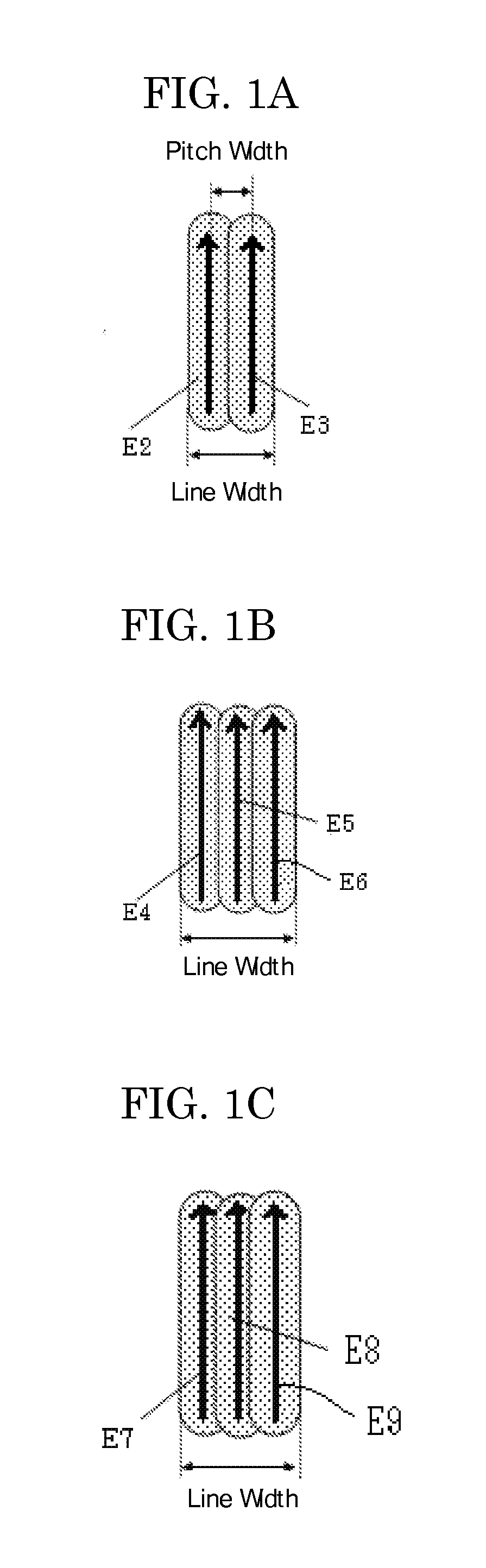

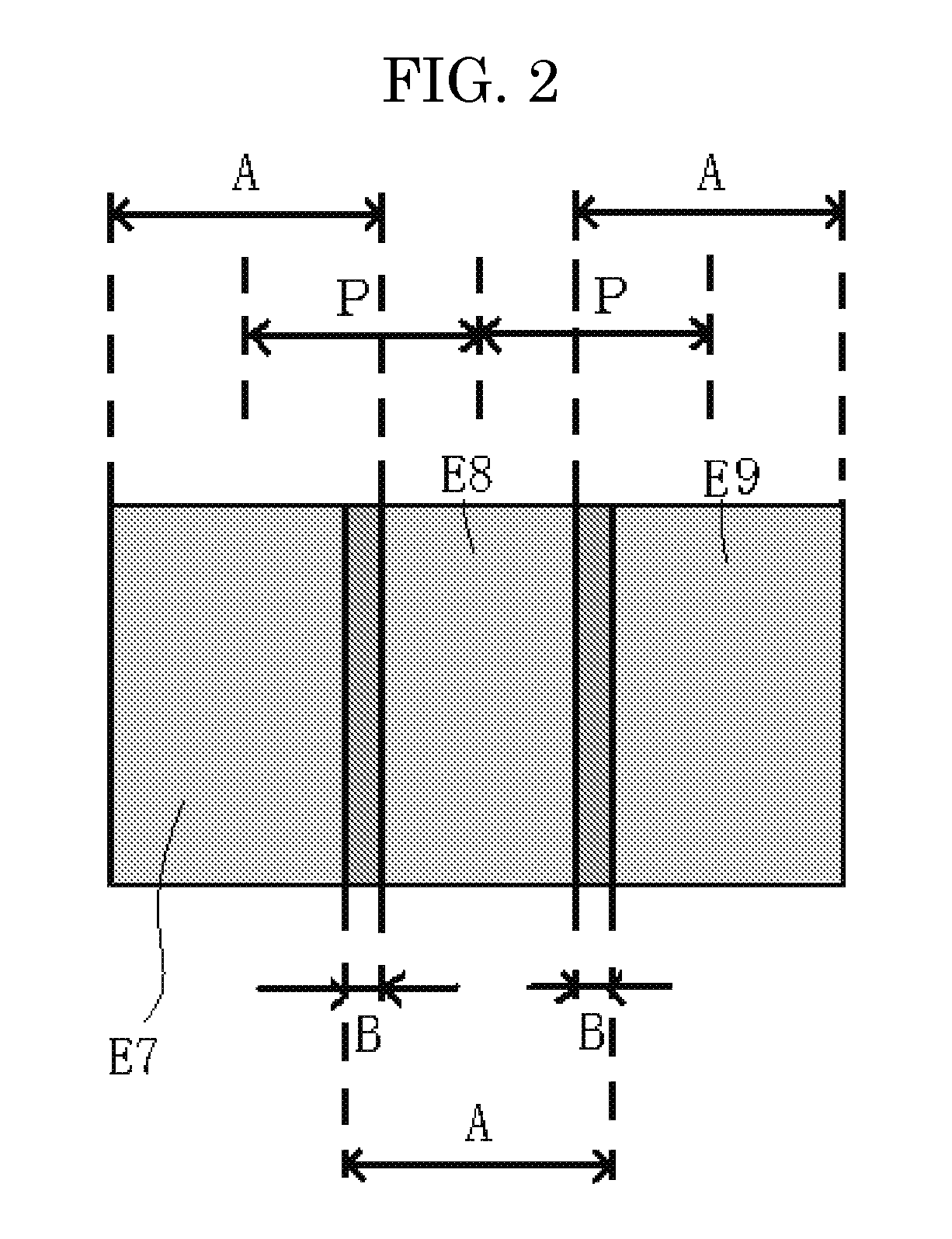

[0308]As a laser, a semiconductor laser, ES-6200-A manufactured by QPC Laser Inc. (center wavelength: 808 nm) was used, and controlled to emit one laser beam so that the output power was 27.3 W, the irradiation distance was 141 mm, the spot diameter was about 0.65 mm, the scanning speed was 2,000 mm / s, the irradiation energy was 21 mJ / mm2, and the line width was 0.42 mm. Then, the laser beam was made to scan a region of the thermoreversible recording medium obtained in Production Example 1 to form a first line written with laser beam (indicated by E7 in FIG. 2) as a line written first.

[0309]Next, another laser beam was controlled so that the output power was 22.2 W, the irradiation distance was 141 mm, the spot diameter was about 0.65 mm, the scanning speed was 2,000 mm / s, the irradiation energy was 17.1 mJ / mm2, and the width overlapped with the first written line was 0.22 mm (pitch: 0.20 mm), and the laser beam was made to scan the thermoreversible recording medium to form a second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com