Wear-resistant and low-friction coatings and articles coated therewith

a technology of low friction and coating, applied in the direction of screw threaded joints, drilling pipes, mechanical equipment, etc., can solve the problems of small movement or vibration, damage to parts, and requiring premature repair or replacement of one or more of the affected components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

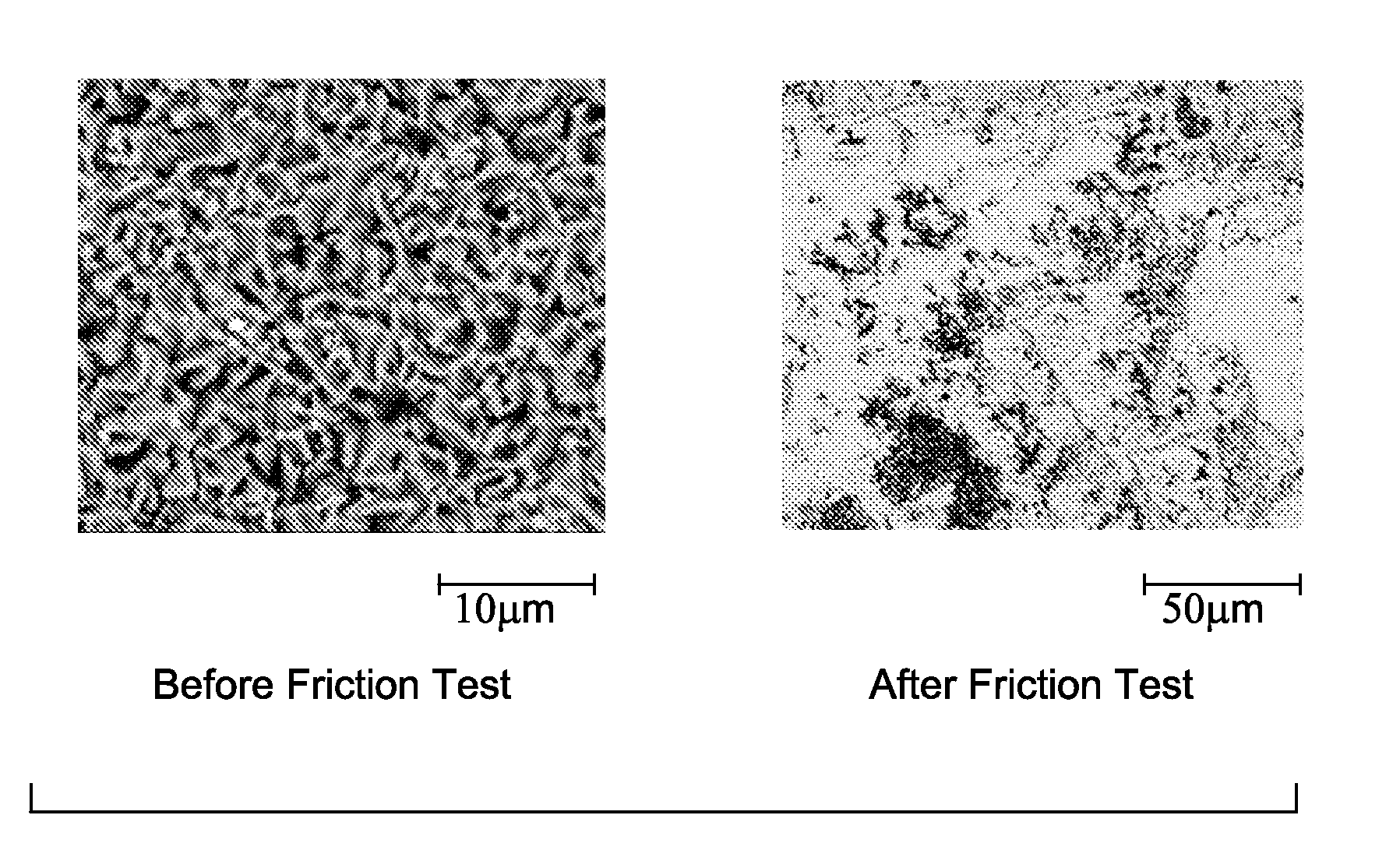

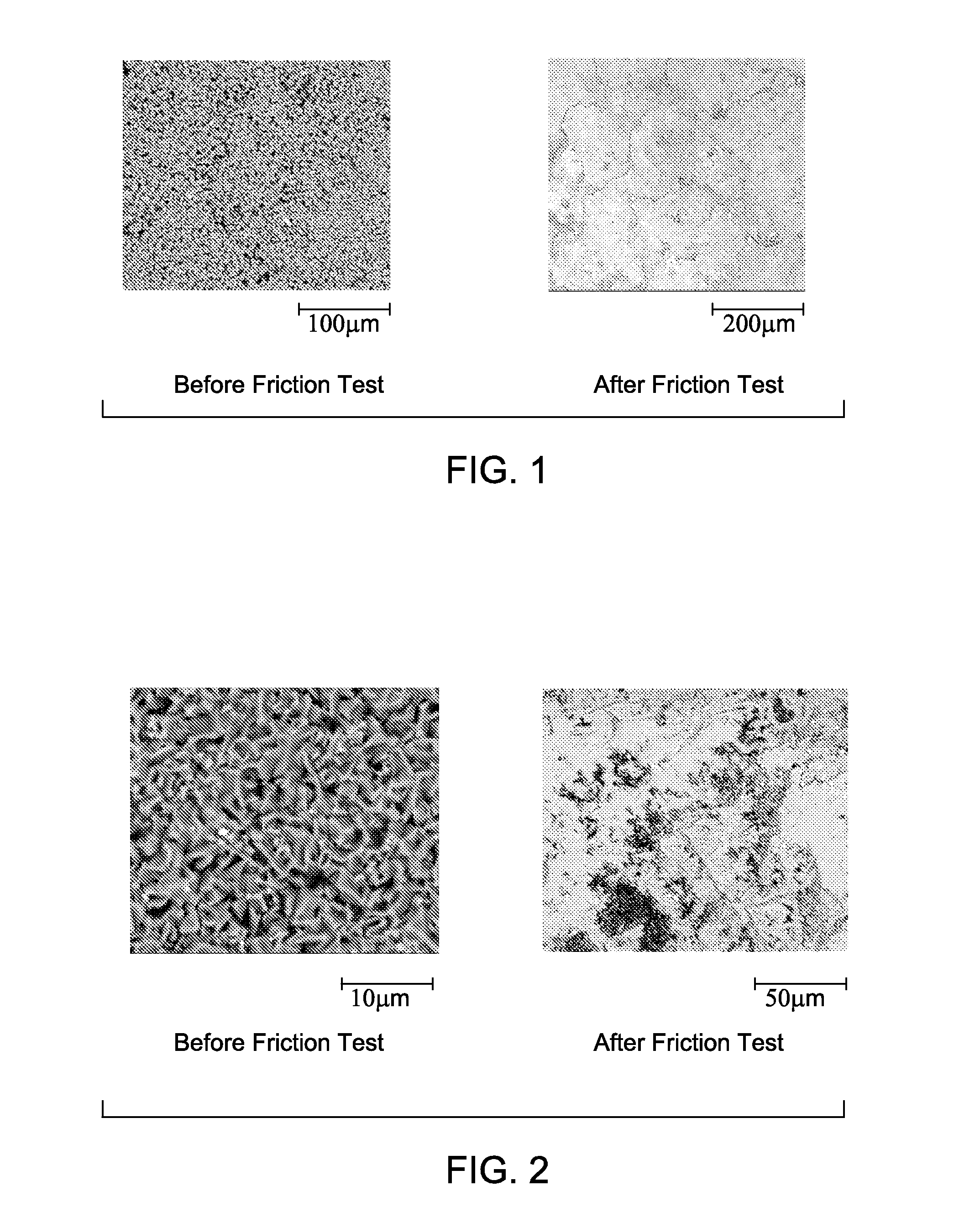

Method used

Image

Examples

example 1

Solid State Method of Preparing of NiO—B2O3

[0061]2.772 grams of NiO powder and 2.585 grams of B2O3 powder were milled together using a rack mill for about 3-6 hours. This powder was then extracted and heat treated at about 400 degrees Celsius for about 1 hour followed by heat treatment at 900 C for about 1 hour.

example 2

Alternate Solid State Method of Preparing NiO-B2O3

[0062]2.772 grams B2O3 or 4.924 grams H3BO3 was dissolved in water and then mixed along with 4.28 grams of NiO or 5.313 grams nickel hydroxide Ni(OH)2 powder. After milling for about 3-6 hours, the water was evaporated and the extracted powder was subjected to heat treatment at about 400 degrees Celsius for about 1 h and then about 900 degrees Celsius for about 1 hour.

example 3

Formation of a Coating Composition (Sample 1)

[0063]8.986 grams of NiCr powder and 60.656 grams of Cr3C2 powder were milled in a high-energy mill using a powder-to-media ratio of about 1:15 for about 10 hours. This mixture was further mixed with 5.357 grams of NiO—B2O3 powder, synthesized using the solid-state method described in example 1. This mixing was carried out in a rack mill for about 1 hour. The powder had particles of particle size less than about 10 microns with about 90 percent particles of particle size about 6 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com