Stable dry powder composition comprising biologically active microorganisms and/or bioactive materials and methods of making

a bioactive microorganism and/or bioactive material technology, applied in the direction of powder delivery, macromolecular non-active ingredients, fungi, etc., can solve the problems of significant damage to the microorganism itself, unstable storage of bioactive microorganisms, and inability to dry supercritical fluid, etc., to reduce the water activity of the formulation, improve the stability of the final product, and accelerate the primary drying of the formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Dry Premixed Formulation

[0090]Several formulation premixes were prepared according to Table 1. Trehalose was obtained from Cargill Minneapolis, Minn. Soy protein isolate was obtained from Fearn Natural Foods, Mequon, Wis. Whey protein Concentrate was obtained from Agri-Mark Inc., Middlebury, Vt. Casein hydrolysate was obtained from Marcor, Carlstadt, N.J., and sodium alginate from ISP Corp., Wayne, N.J. All ingredients were combined together and uniformly mixed (Table 1).

TABLE 1Formulations Premix composition (weight percent)ProteinhydrolysateConstituentSoy premixWhey premixpremixSodium Alginate3.03.03.0Inulin5.05.05.0Trehalose75.375.375.3Soy protein Isolate14——Whey protein—14—concentrateCasein Hydrolysate2.72.716.7

example 2

Stable Dry Powder Containing Probiotic Bacteria

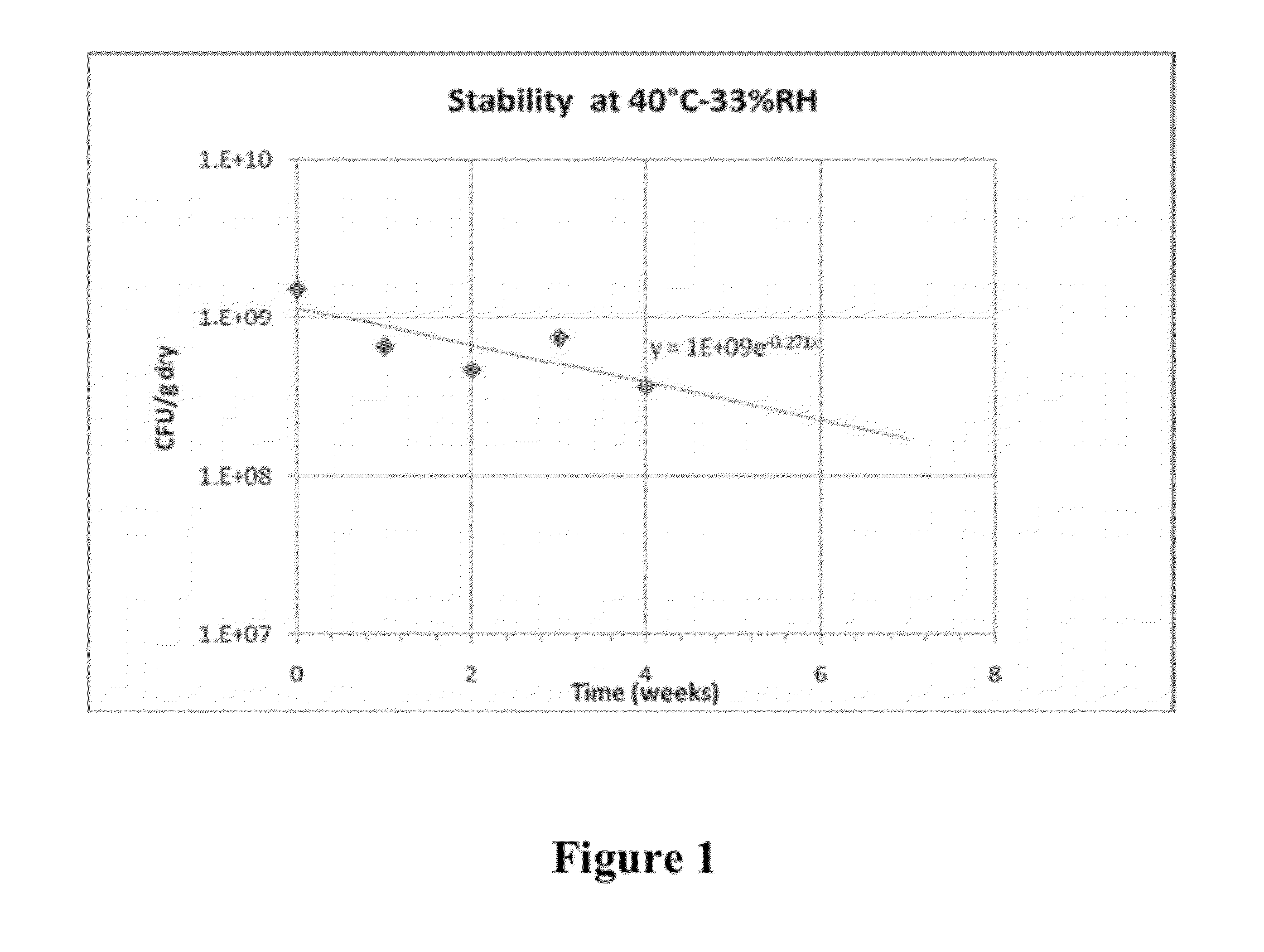

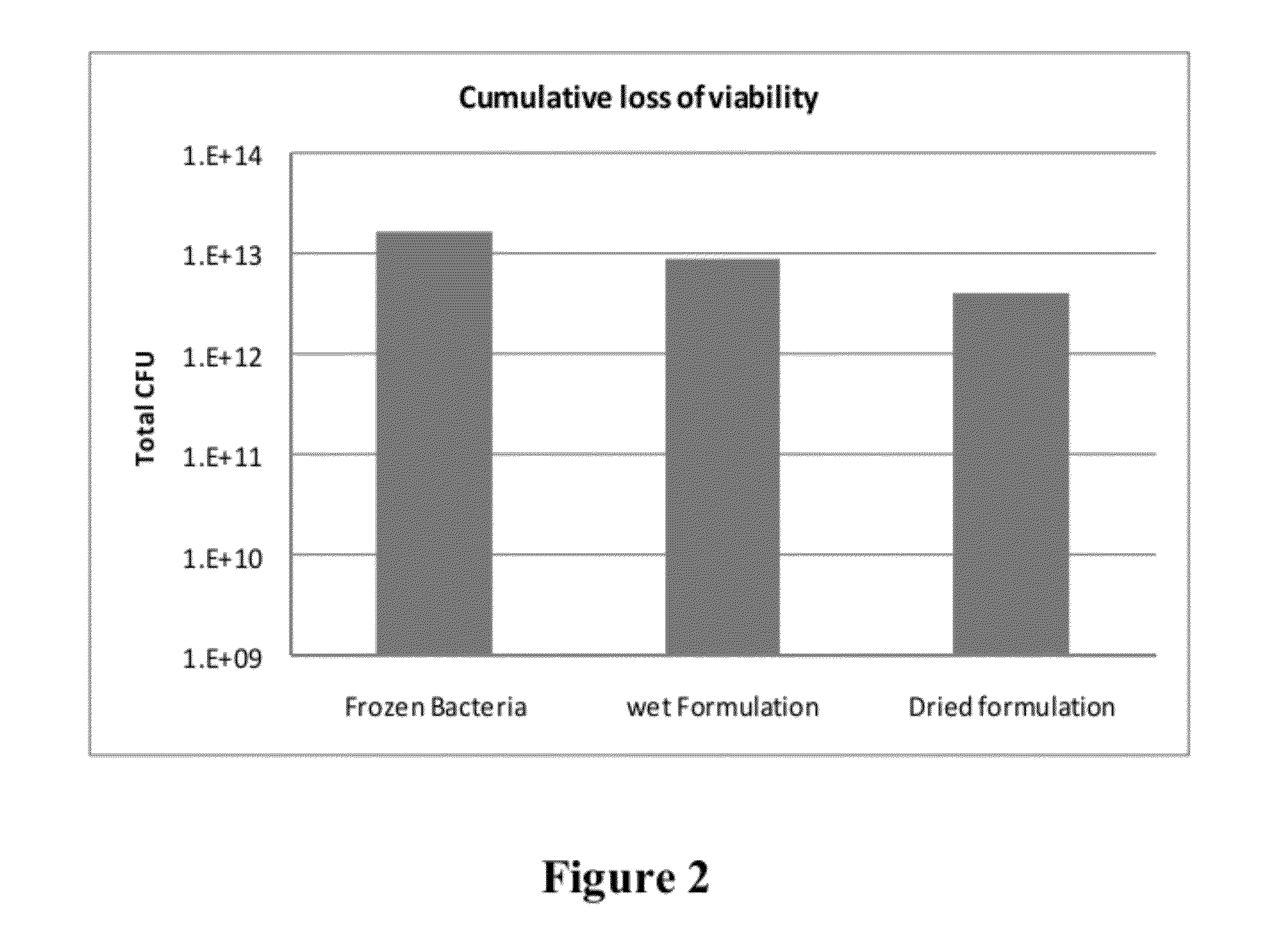

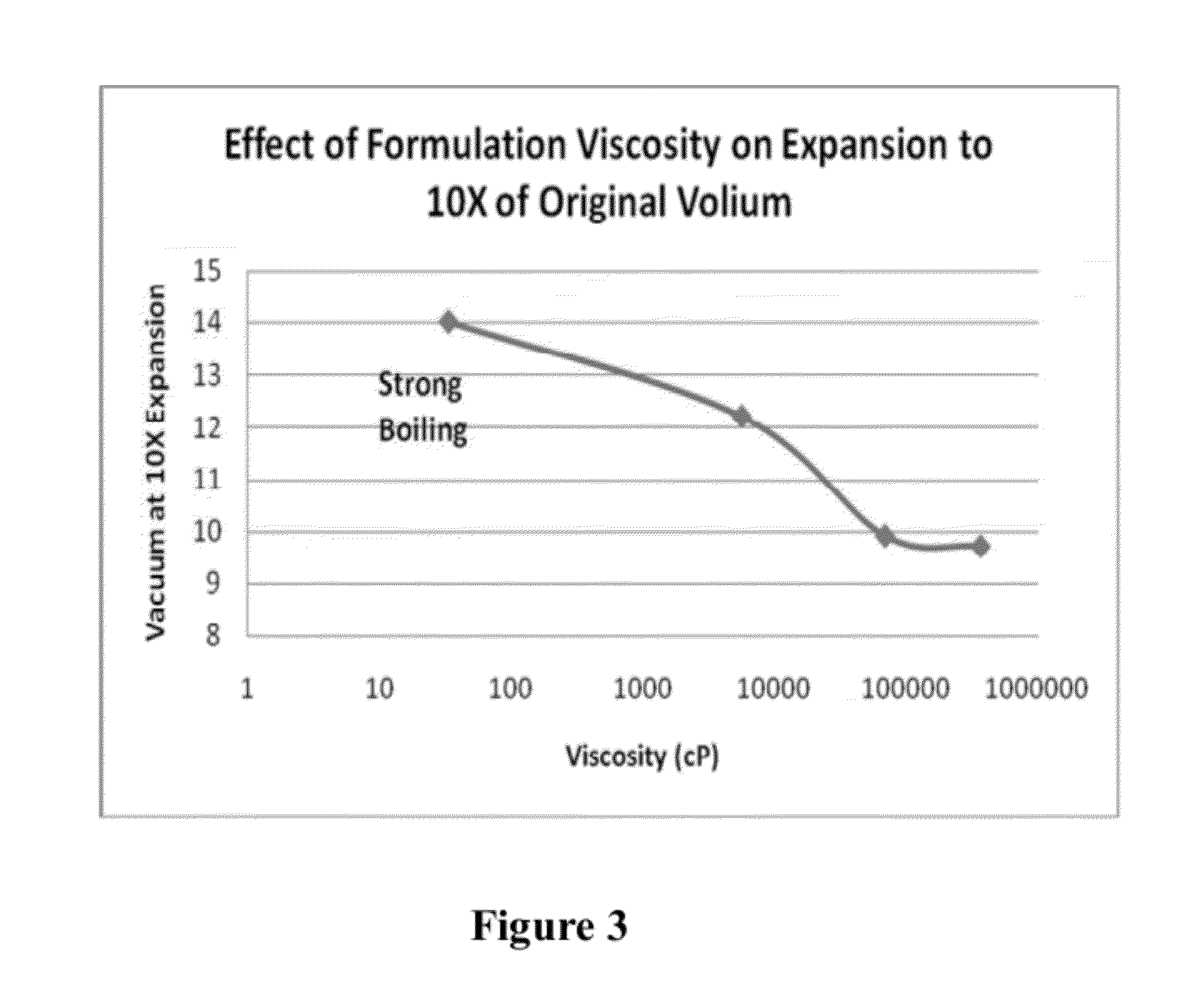

[0091]Lactobacillus Acidophilus (100 g frozen concentrate from a lab fermentation harvest) was thawed at 37° C. Protein hydrolysate premix (100 g, Table 1) was slowly added to the thawed slurry of probiotic bacteria in a jacketed dual planetary mixer (DPM, 1 qt, Ross Engineering, Inc. Savannah, Ga.). Mixing was carried out under mild vacuum (25 Torr) at 40 RPM and 37° C. for 10 minutes. The homogenous slurry was evenly spread on a tray at a loading capacity of 200 g / sq ft and the tray placed on a shelf in a freeze drier (Model 25 SRC, Virtis, Gardiner, N.Y.). Shelf temperature was set above the freezing temperature of the slurry at −5° C. to cool, but not to freeze, the slurry. Vacuum pressure (3 Torr) was applied when the formulation temperature reached about −1° C. The slurry starts to gently degas when vacuum reached about 7 Torr. When the vacuum reached 3 Torr, the shelf temperature was increased to 50° C. The formulation temperatur...

example 3

Preparation of a Hydrogel Formulation

[0094]Concentrated probiotic slurry was prepared according to Example 2 but using the whey protein premix of Table 1. To this slurry, 0.5 g of dibasic calcium phosphate was added, followed by 0.5 g of gluconolactone. The slurry was allowed to harden at room temperature over the next 2 hours to form a solid hydrogel. The firm gel was sliced to thin and long threads, using a commercially available slicer / shredder. The thin threads were loaded on a tray at a loading capacity of 200 g / sq ft and placed in a freeze drier for drying as described in Example 2. Four hours after establishing maximum vacuum of 0.1 Torr, the dried product was taken out of the freeze drier. The water activity (Aw) of the formulation was 0.05 (Measured by HygroPalm Aw1, Rotonic Huntington, N.Y.). The dry formulation was further ground to fine powder using standard hammer milling equipment and sieved through 50-250 micron screens. FIG. 11 present a flow chart of the method of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com