Multilayers having reduced perpendicular demagnetizing field using moment dilution for spintronic applications

a moment dilution and demagnetizing field technology, applied in the field of composite magnetic structure, can solve the problems of destroying a thin tunnel barrier made of alox, mgo, or the like, and using external magnetic fields generated by current carrying lines to switch the magnetic moment direction of the free layer becomes problematic, and achieves high mr ratio, high mr ratio, and high mr ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

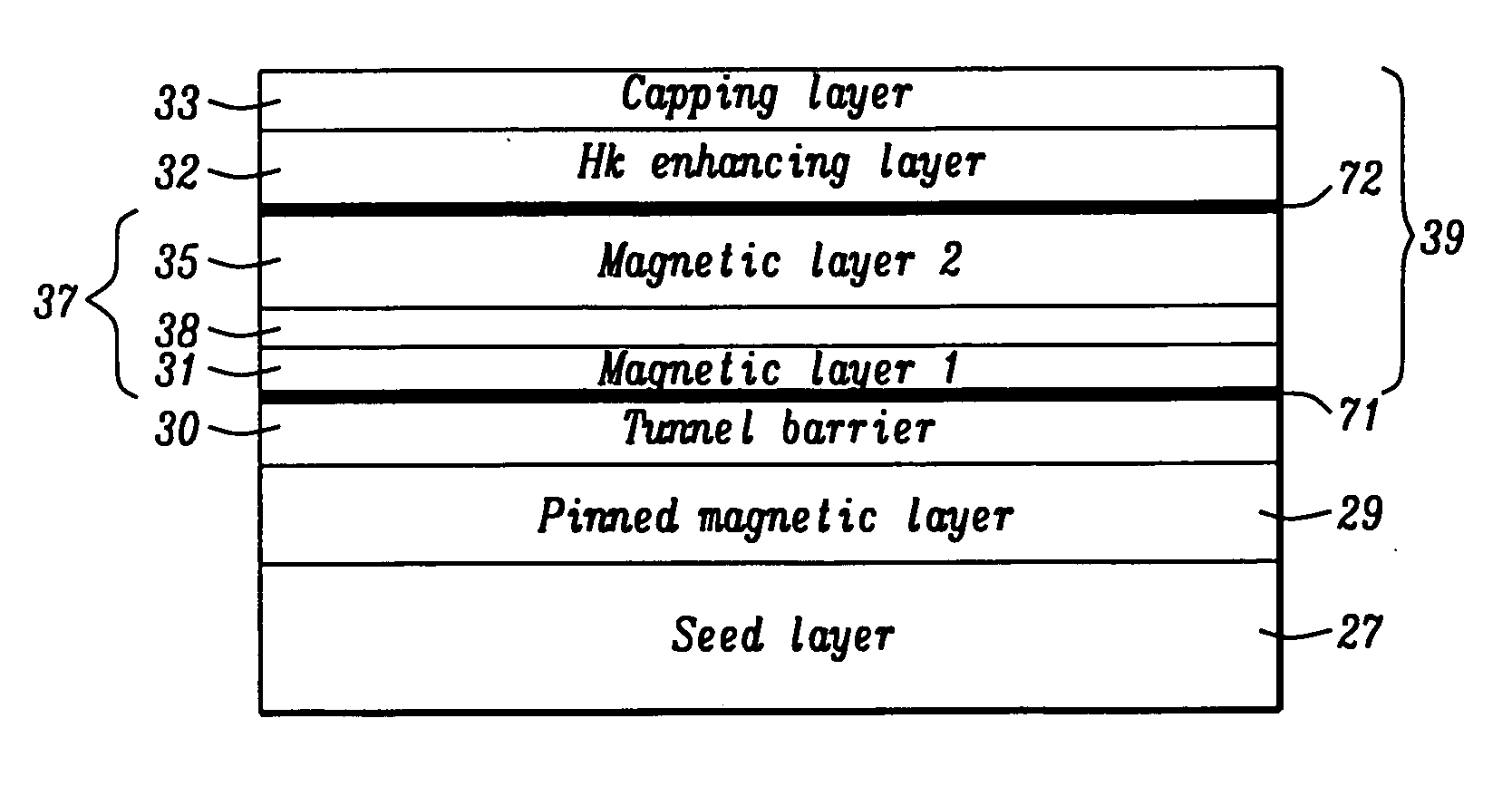

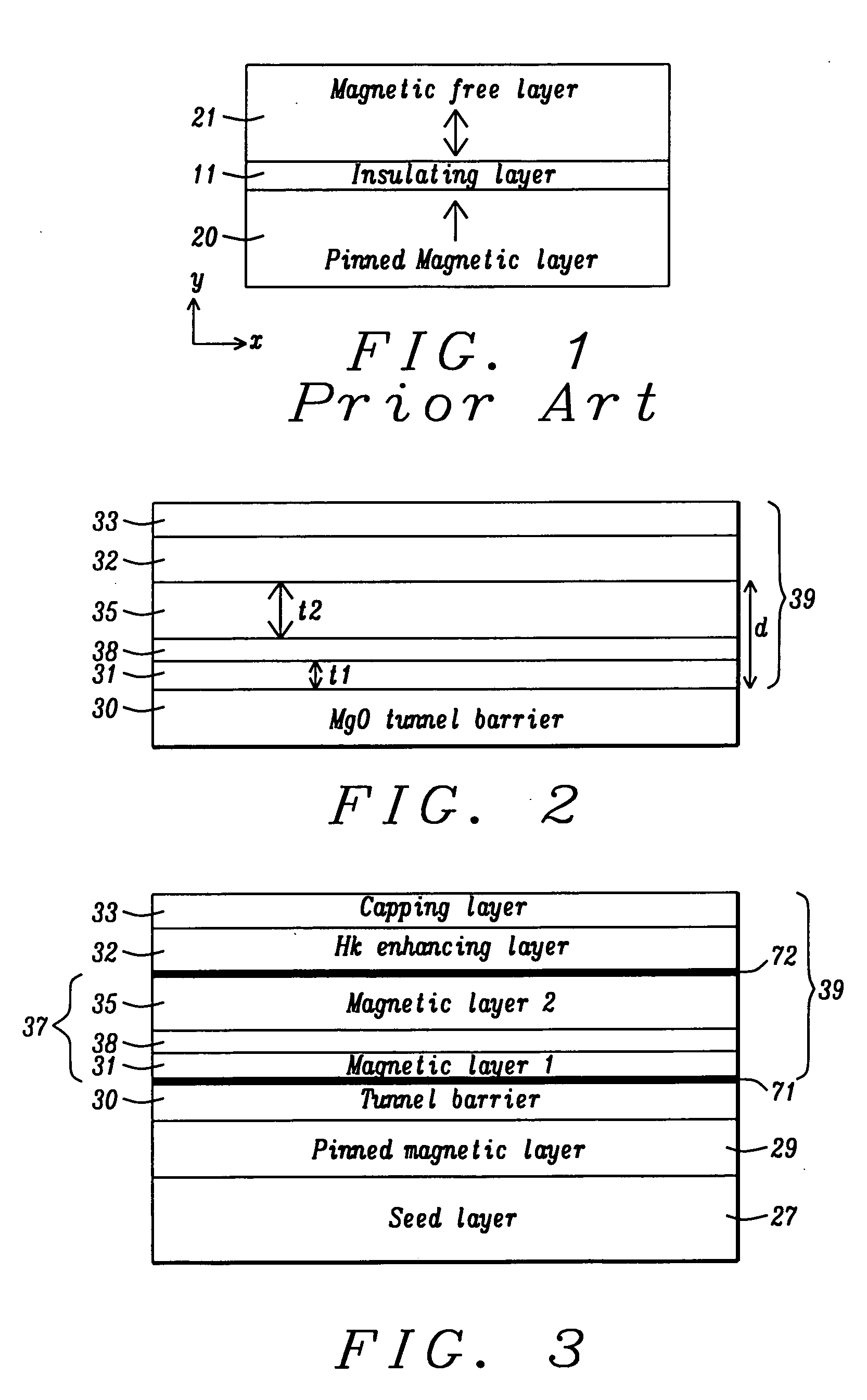

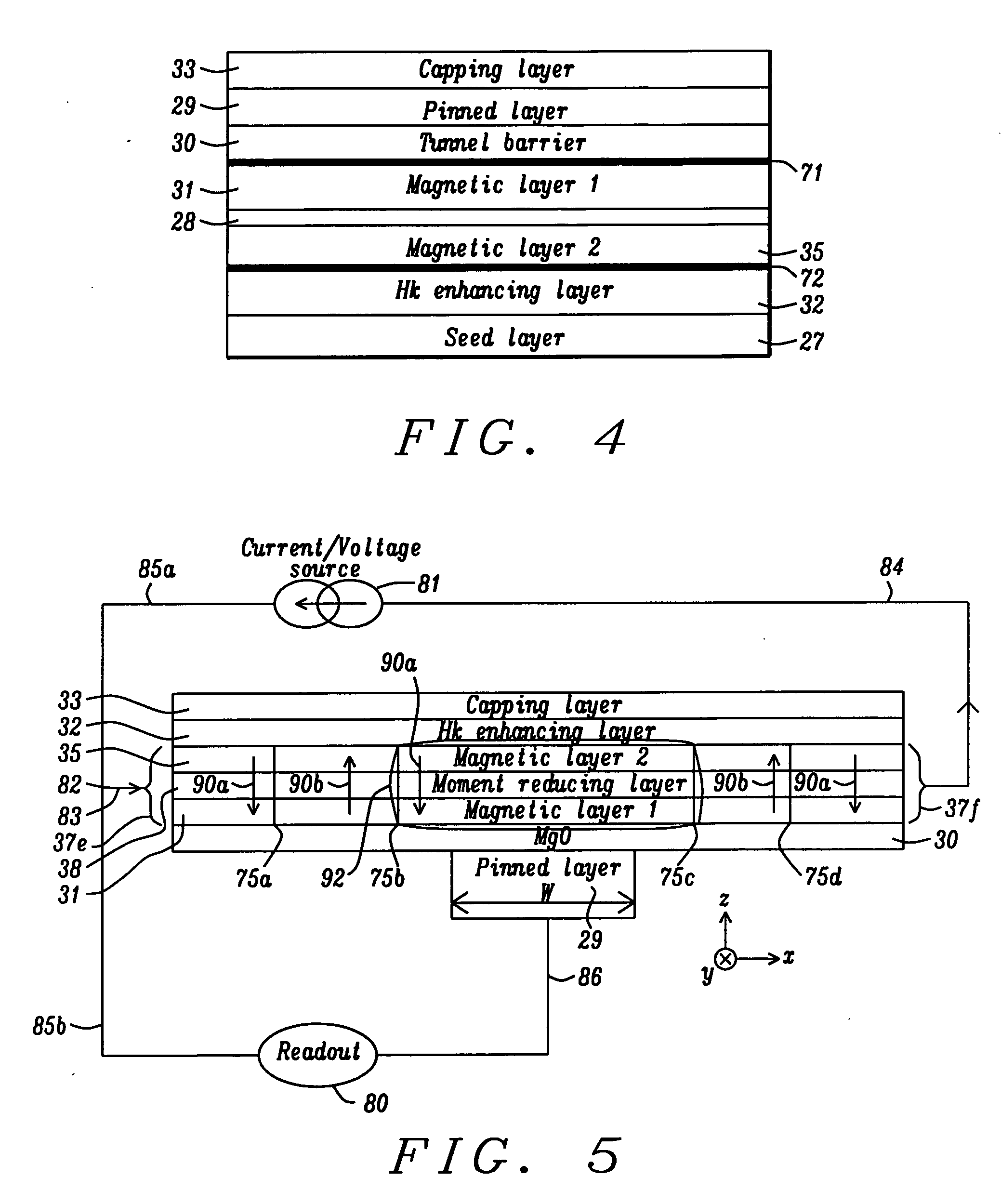

[0038]The present invention is based on the discovery that the perpendicular demagnetizing field in a free layer may be reduced by inserting a moment diluting material thereby increasing the perpendicular anisotropy field to improve thermal stability and lower the RA value in an out-of-plane embodiment. Although the exemplary embodiments depict bottom spin valve and top spin valve configurations in a MTJ element, the present invention also encompasses a dual spin valve as appreciated by those skilled in the art. The magnetic element including the aforementioned composite free layer as a digital information storage layer may be employed in a MTJ as part of a STT-MRAM or other spintronic device, or as propagation medium for a domain wall in a domain wall motion device. The terms interfacial perpendicular anisotropy and surface perpendicular anisotropy may be used interchangeably. A Ms reducing layer is also referred to as a moment diluting layer.

[0039]In a related patent application S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com