Method and arrangement for utilizing recirculation for high temperature fuel cell system

a fuel cell and high temperature technology, applied in the direction of fuel cells, electrical generators, sustainable buildings, etc., can solve the problems of long start up and shutdown times, mechanical and chemical compatibility problems, pollution when combusted, etc., to reduce temperature conditions, reduce temperature conditions, and reduce the effect of temperature conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

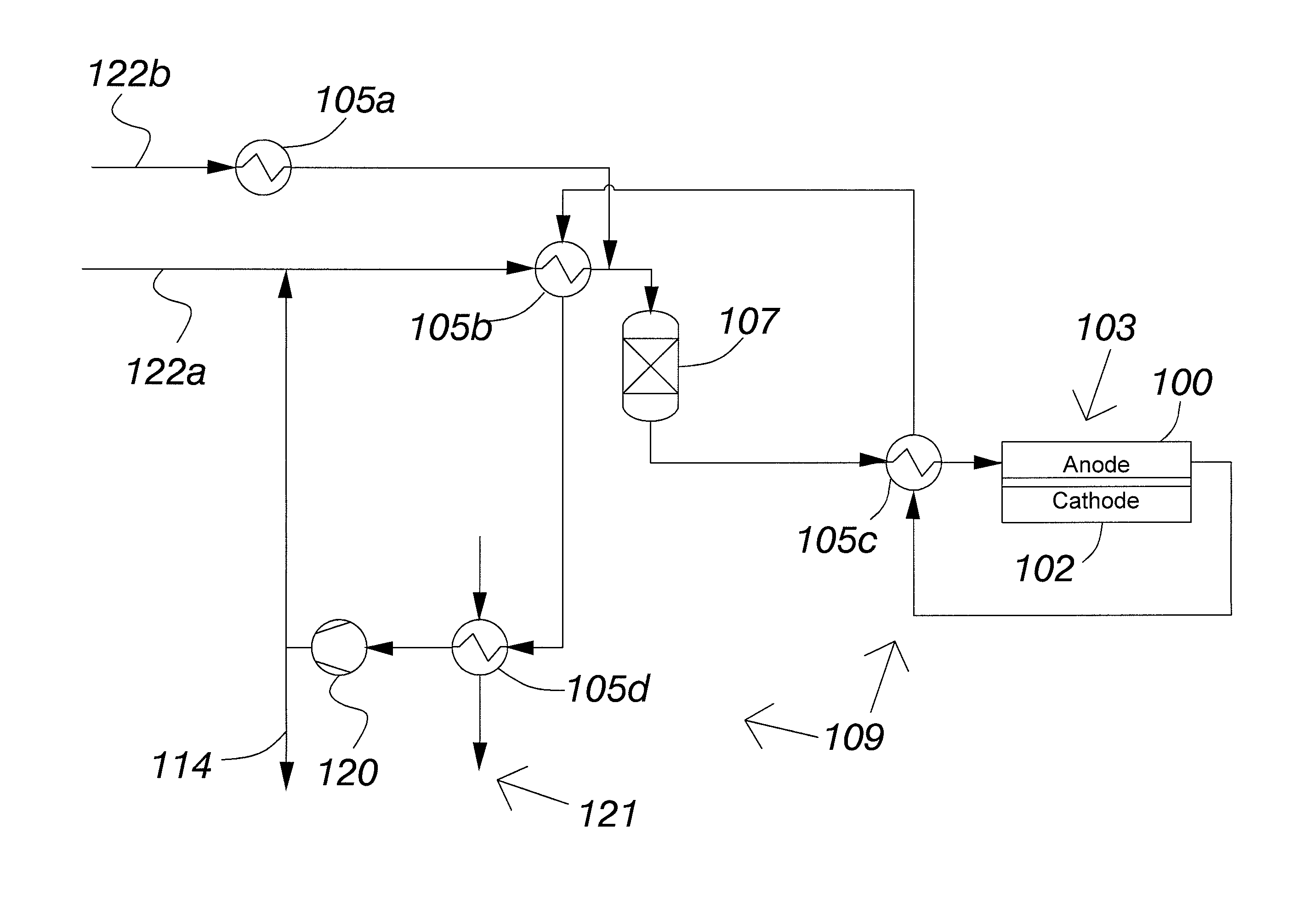

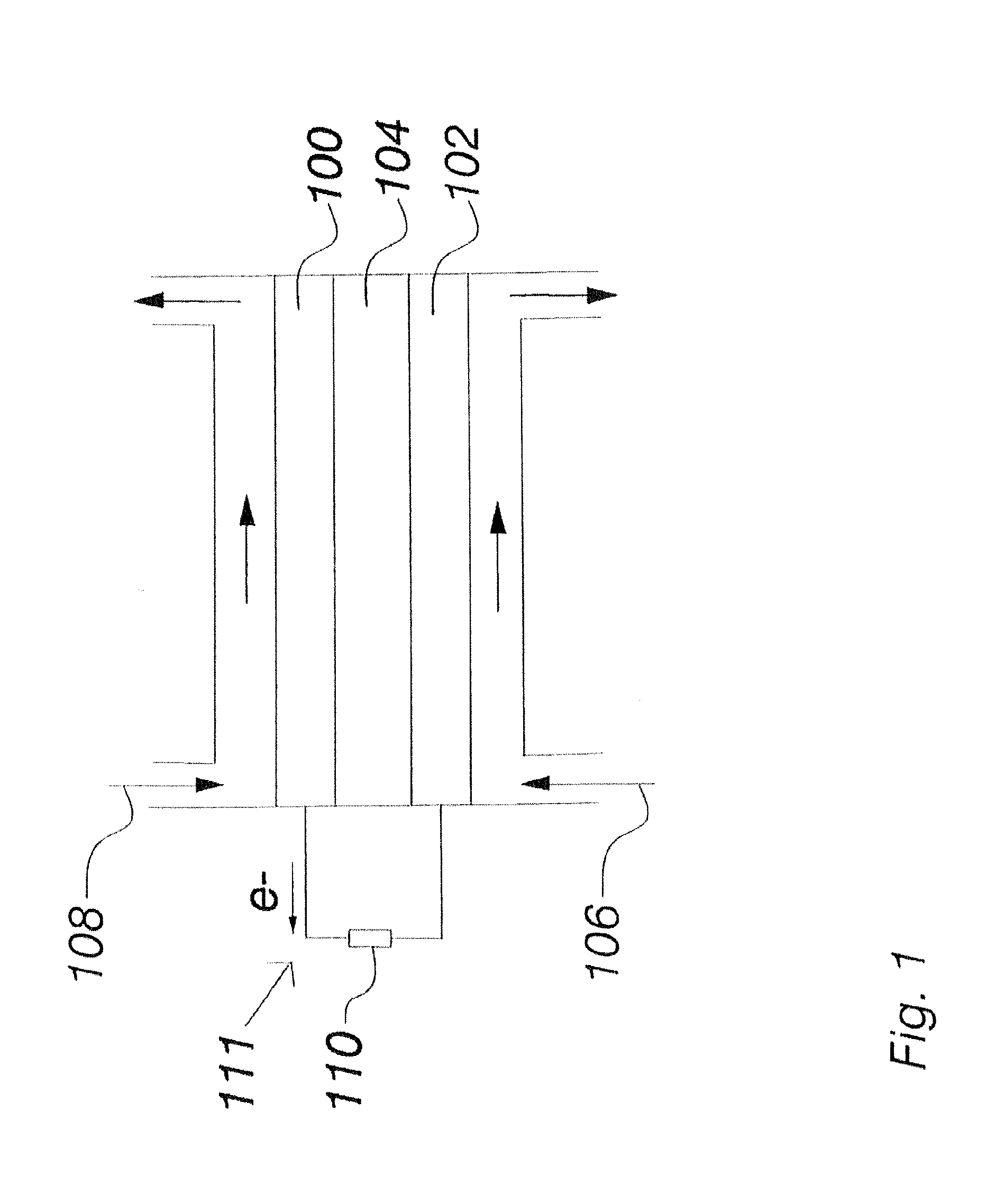

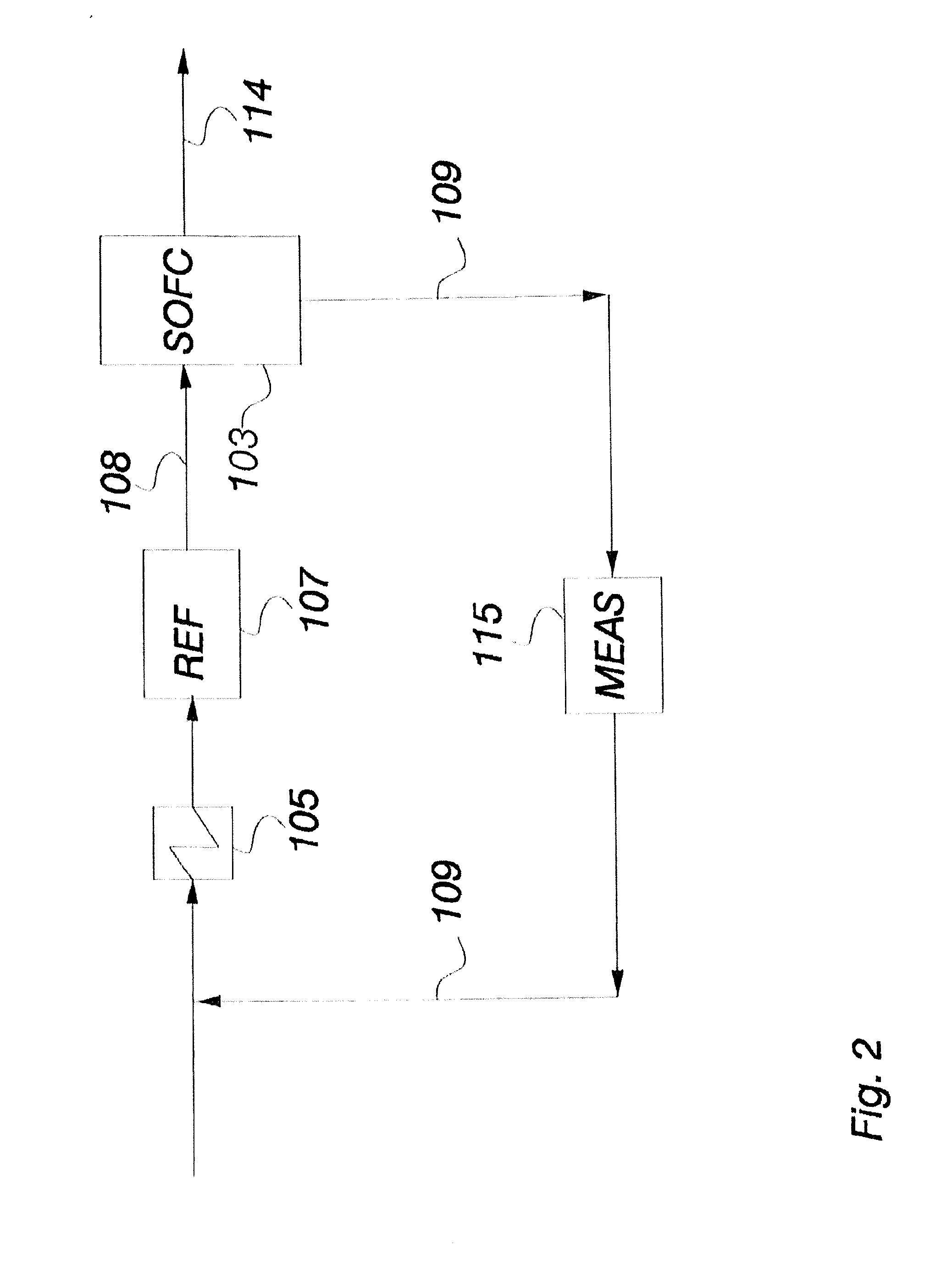

[0029]In accordance with an exemplary embodiment, a fuel cell system is disclosed, wherein the use of purge gas and external water connections can be minimized or even completely neglected in start-up and shutdown situations of a fuel cell system. In accordance with an exemplary embodiment, an arrangement utilizing recirculation for high temperature fuel cell system, each fuel cell in the fuel cell system including an anode side, a cathode side, and an electrolyte between the anode side and the cathode side, and the fuel cell system can include means for performing anode side recirculation flow of reactants. The arrangement can include means for accomplishing a recycle ratio of, for example, 70% or more for the recirculation flow, means for feeding to the recirculation a feed-in flow, which can include high oxygen content, the feed-in flow being, for example, 30% or less of entire flow, means for performing heat exchanging to provide substantially low temperature conditions in the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outlet temperature | aaaaa | aaaaa |

| outlet temperature | aaaaa | aaaaa |

| outlet temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com