Process control methods for obtaining and maintaining a desired moisture content of spray dried plasma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

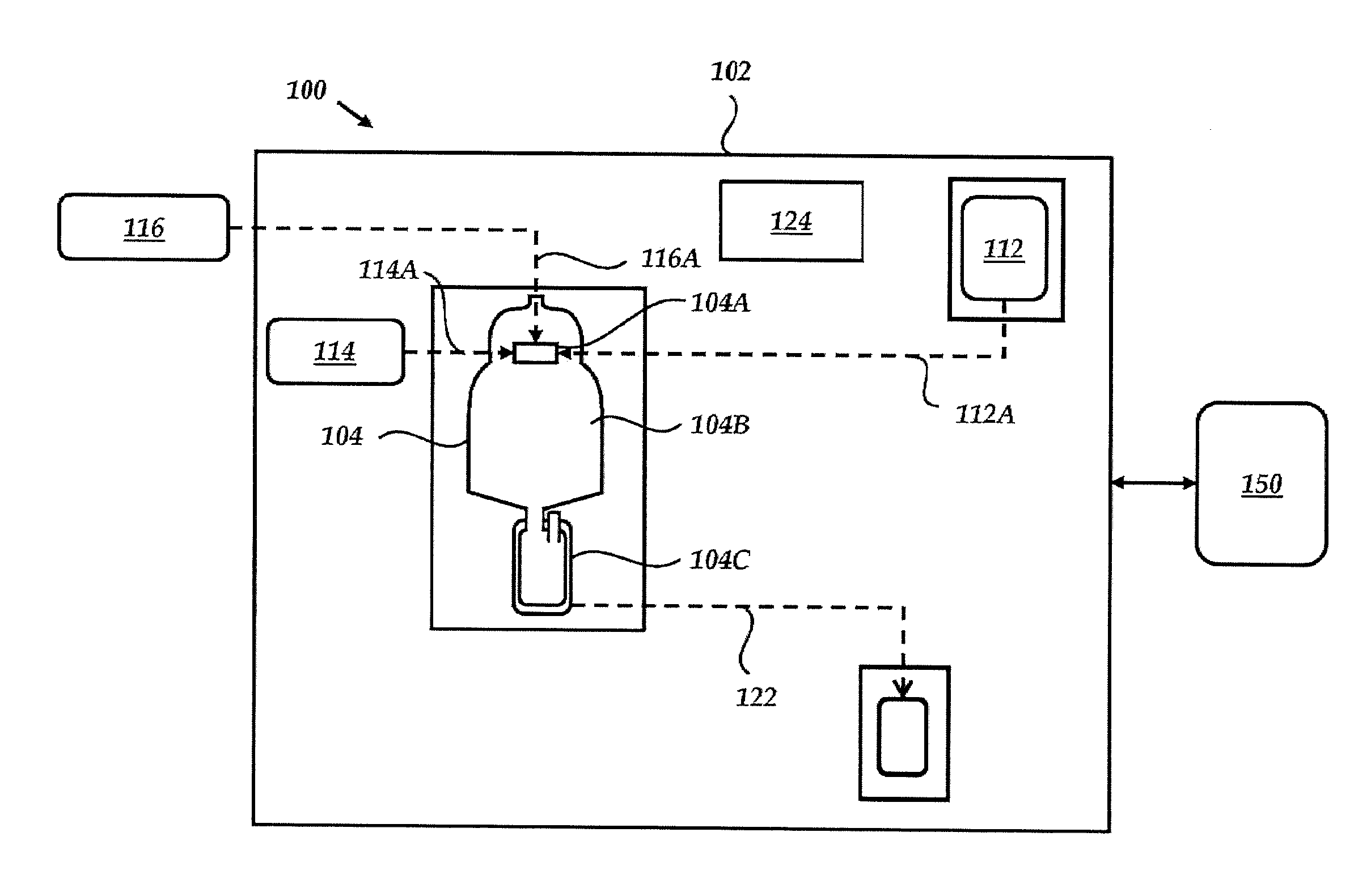

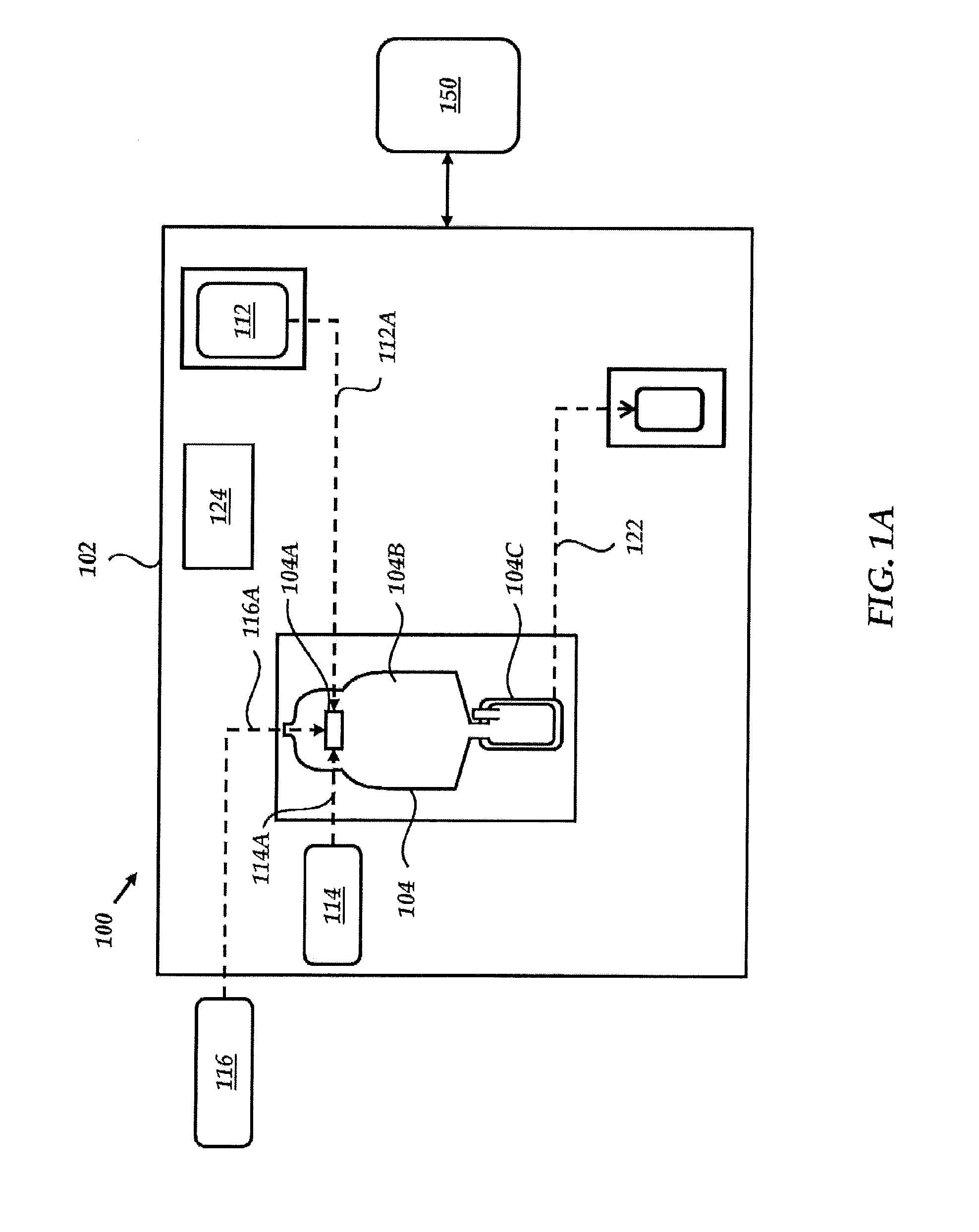

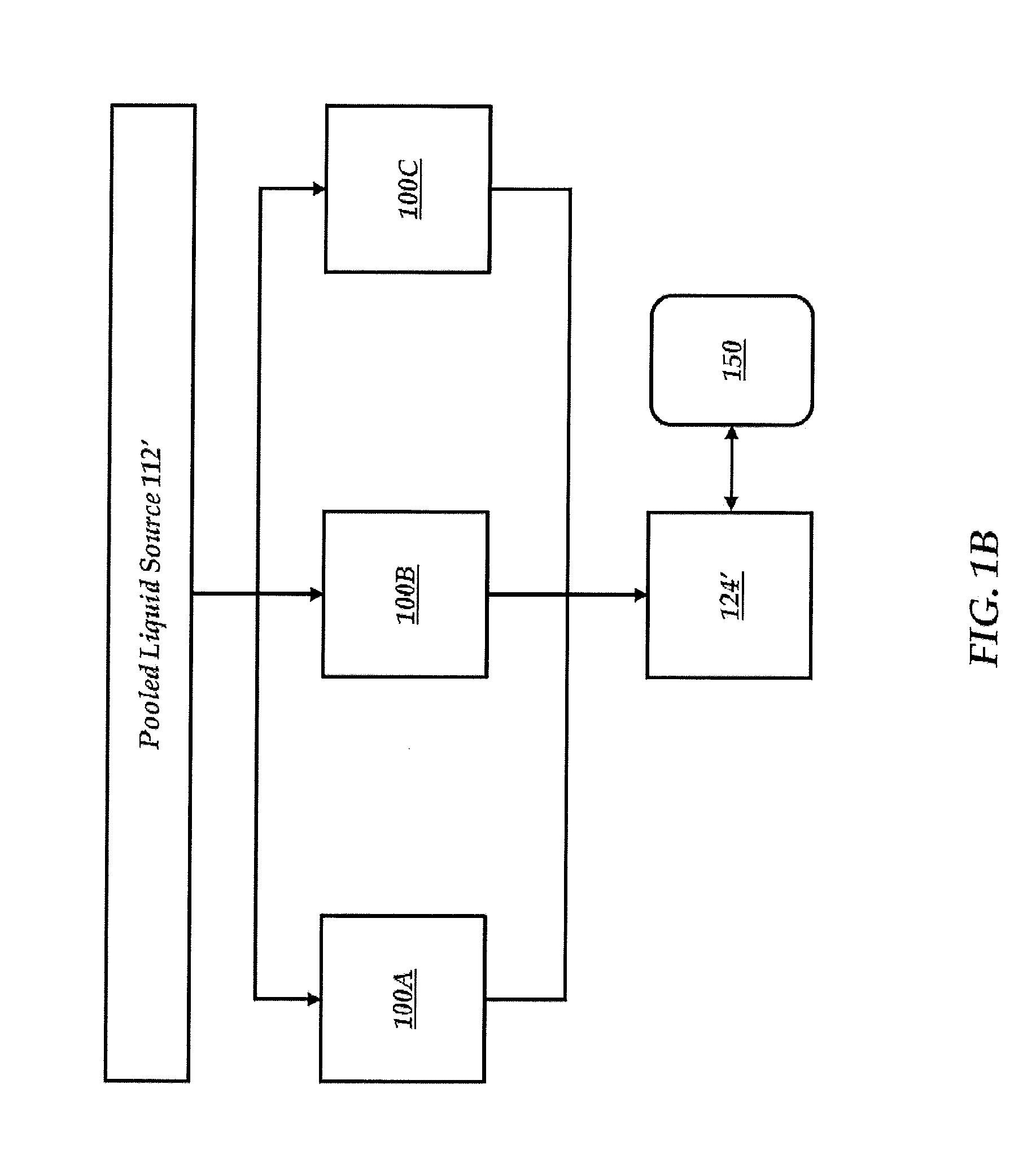

Image

Examples

example 1

[0184]Plasma Protein Activity Correlated with Drying Gas Exhaust Temperature

[0185]We found that the most important parameter with respect to protein viability in dried plasma was the drying gas exhaust temperature. If dried plasma is exposed to an exhaust temperature higher than 60° C., even briefly, plasma protein activity degrades. Please note, during the drying process the surface of the wet plasma droplets is exposed to 125° C. but the droplet remains cool due to the evaporation process. A significant improvement in process consistency was achieved by actively controlling the exhaust temperature by varying the speed of the drying gas pump and, thus, the flow rate of the drying gas through the spray drying apparatus.

[0186]When bleeding occurs, the body causes coagulation factors, such as Fibrinogen and / or Factor V, to combine and produce a clot which stops bleeding. Insufficient protein activity may impair clot formation, resulting in excessive bleeding. Accordingly, it is desira...

example 2

[0189]Controlling Exhaust Gas Temperature Maintains Consistent Spray Drier Temperature

[0190]In this study, 220 mL of plasma was spray dried on the Velico Medical Alpha 1 spray drier apparatus using the configuration show in FIG. 8. Input parameters were as follows: Plasma fluid flow rate: 10 mL / minute; Aerosol gas flow rate: 20 L / minute; Drying gas initial temperature: 125° C.; Drying gas flow rate 550-750 L / minute; Drying gas exhaust temperature: 52° C. The exhaust gas temperature was maintained at about 52° C. by varying the drying gas flow rate.

[0191]To map the gradient in the spray drier during spray drying, temperature probes were placed at the drying head, the inlet of the collection filter bag and at the exhaust of the collection filter bag. In FIG. 9, temperature sensor T5 measures the inlet drying gas temperature; temperature sensor T8 measures the inlet collection filter bag temperature, temperature sensor T6 measures the exhaust gas temperature as it leaves the collection...

example 3

[0193]Plasma Powder Moisture Correlated with Exhaust Gas Temperature

[0194]The correlation between spray drier exhaust gas temperature and moisture content of the spray dried plasma was determined. Spray dryer parameters used were[0195]Drying Gas Flow Rate: 600-850 L / min[0196]Drying Gas Initial Temperature: 125-135° C.[0197]Drying Gas Exhaust Temperature: 30-70° C.[0198]Fluid Flow Rate: 8-10 ml / min[0199]Velico Medical Alpha 1 Spray Dryer

[0200]Exhaust gas temperature was controlled at various temperatures from 30° C. to 70° C. Residual moisture in the dried plasma was measured by the Karl Fisher method for dried plasma collected in the collection filter. FIG. 16 shows the residual moisture content of the dried plasma ranged from about 15% when the exhaust temperature was maintained at about 30° C. to about 4.0% when the exhaust temperature was maintained at about 70° C. As indicated above, when the spray drier was operated to keep the exhaust gas temperature from about 55-60° C., the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com