Method of exfoliating and functionalizing graphite anode

a graphite anode and functionalization technology, applied in the direction of graphite, electrolysis organic oxidation, electrolysis components, etc., can solve the problems of difficult scaling up, difficult processing of graphene, and unfavorable material preparation by the above methodology techniqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The present invention will be described with reference to illustrative embodiments. For this reason, numerous modifications can be made to these embodiments and the results will still come within the scope of the invention. No limitations with respect to the specific embodiments described herein are intended or should be inferred.

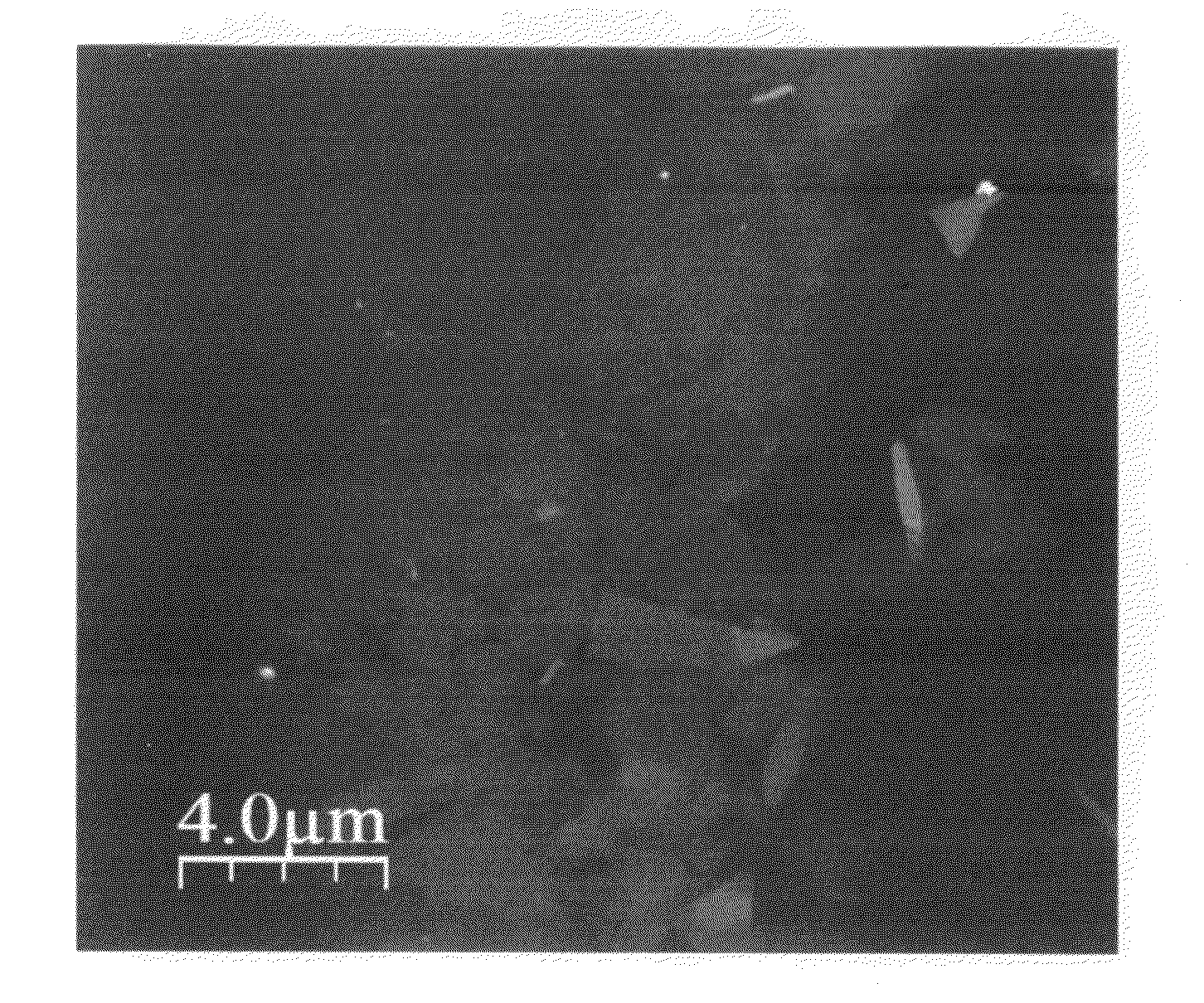

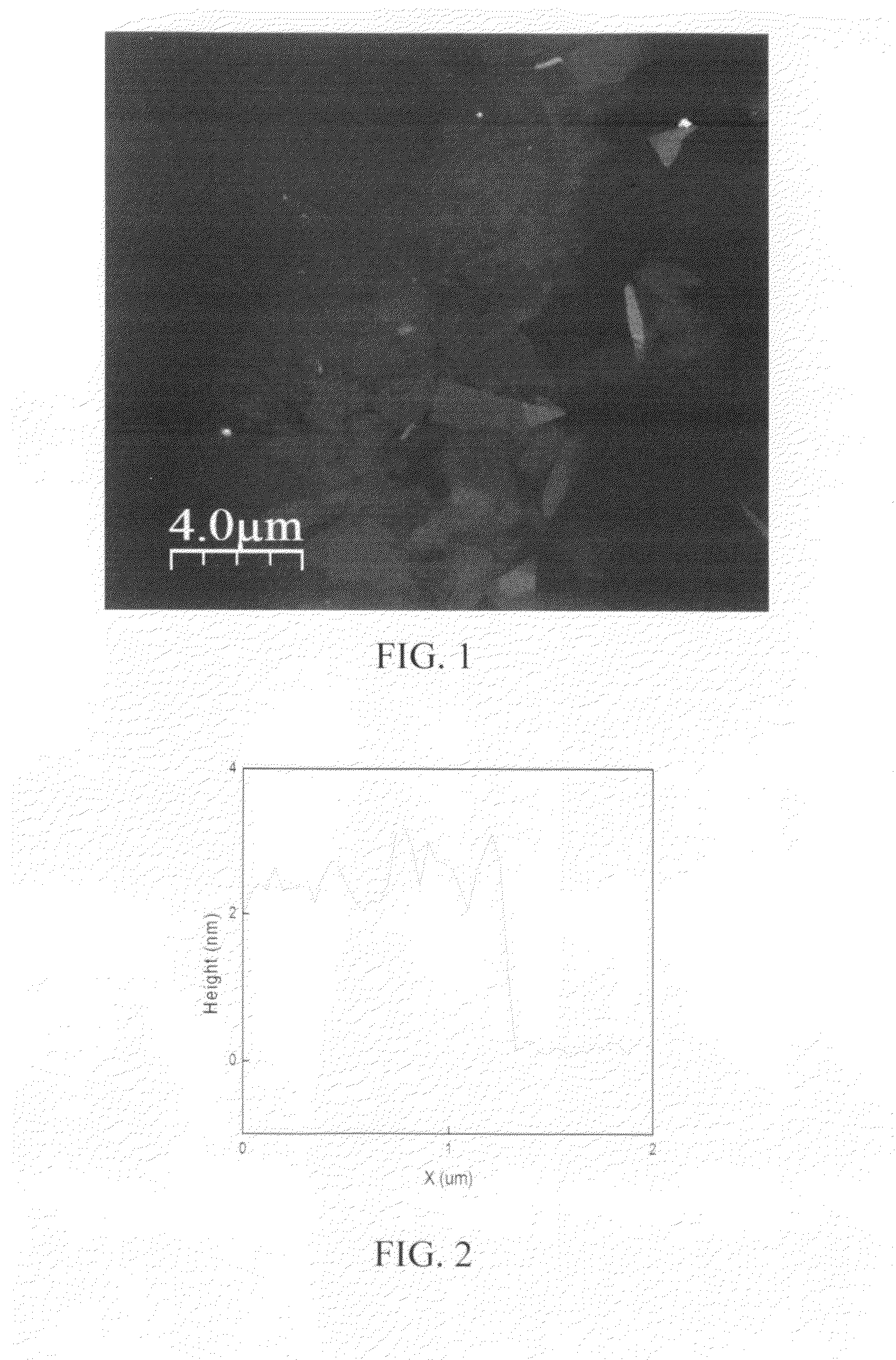

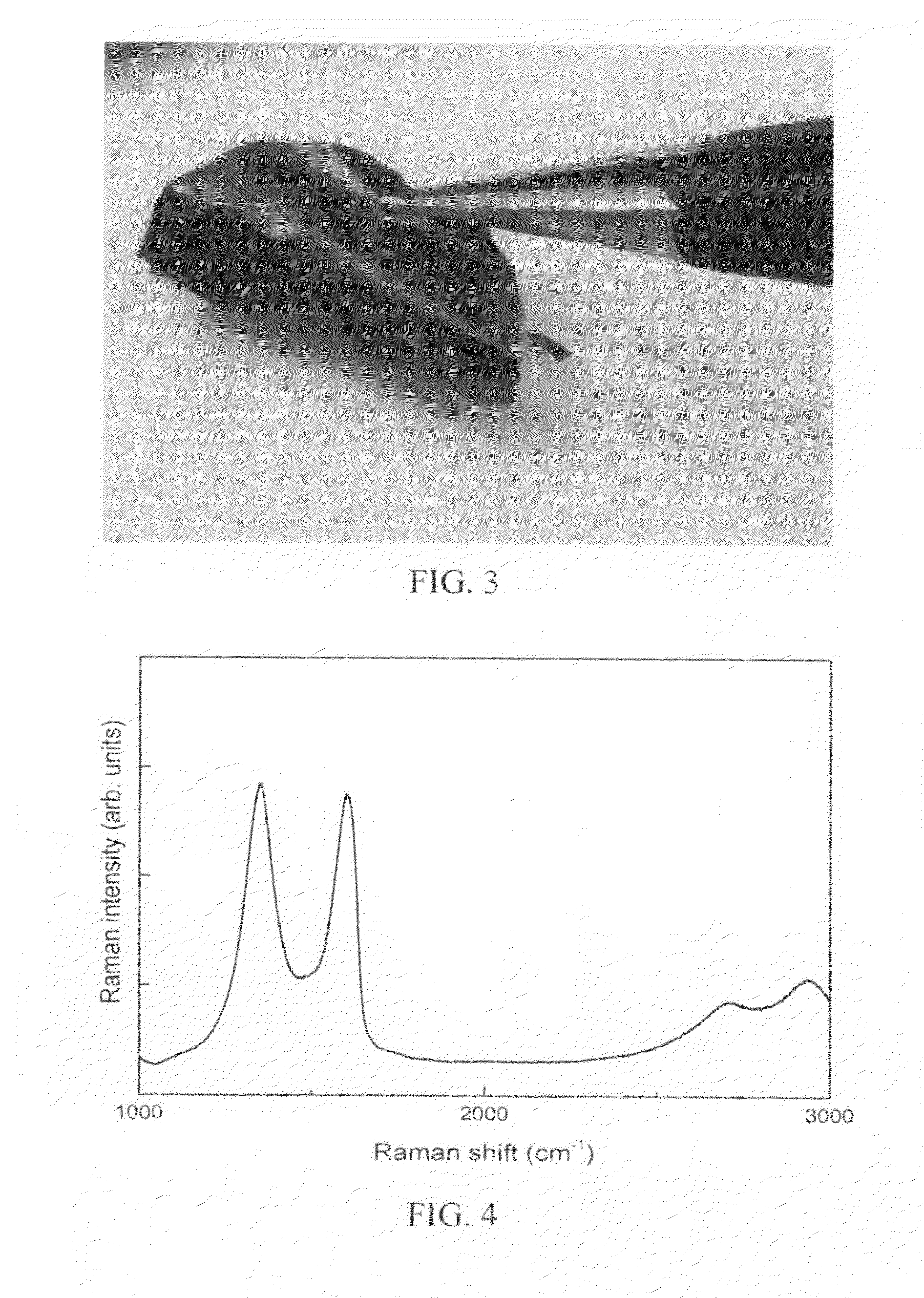

[0018]With reference to FIGS. 1 to 5, a method of producing graphene oxide in an electrochemical cell according to a preferred embodiment of the present invention comprises steps of:

[0019]A. providing an electrochemical cell with a first graphitic electrode and a second conductive electrode, wherein the first graphitic electrode is made of any one of HOPG, natural graphite, and synthetic graphite, the first graphitic electrode is held at a most positive potential, and the second conductive electrode is conductive

[0020]B. providing an electrolyte of a solvent in the electrochemical cell, wherein the electrolyte has specific oxygen to produce graphene o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com