Means for Controlled Sealing of Endovascular Devices

a technology of endovascular devices and sealing mechanisms, applied in the field of endoluminal devices, can solve the problems of life-threatening, severe hemorrhage or other complications, sudden death, and inability of the vessel to conduct fluids, and achieve the effects of preventing leakage, excellent sealing, and eliminating prosthetic-annular incongruen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Hydrogel with Rapid Swelling

[0156]Studies to identify hydrogels having substantial swelling in a short time were performed. The main factors that influence swelling of a hydrogel based on polymerisation and cross-linking of synthetic monomers are:

[0157]Type of monomer

[0158]Type of cross-linker

[0159]Concentration of monomer and cross-linker in the gel

[0160]The ratio of monomer to cross-linker

[0161]Acrylic acid polymers are capable of rapid swelling and are regarded as having good biocompatibility. A number of commercially available cross-linkers can be used to crosslink the polymers to form a hydrogel. These include Bis acrylamide, di(ethylene glycol)diacrylate, and poly(ethylene glycol)diacrylate (MW 500 Da).

[0162]Materials and Methods

[0163]Studies were conducted to identify appropriate combinations of acrylic acid concentration, type of cross-linker, concentration of cross-linker and ratio of monomer to cross-linker. The basic composition of the formulations used to ...

example 2

Assessment of Alternative Cross-Linkers for Hydrogels

[0173]The principle behind the selected cross-linkers is that rather than having a short cross-linker with only two polymerizable groups, a type of long-chain hydrophilic polymer with multiple polymerizable groups is being used. A much stronger hydrogel is obtained compared to short chain, divalent cross-linkers. While these gels are very firm, they possess very good swelling characteristics. Very strong gels do not normally swell very much.

[0174]Poly vinyl alcohol (PVA) was derivatized with allyl glycidyl ether under alkaline conditions. Gels were made by combing acrylic acid with the PVA-based cross-linker and then polymerizing the mixture by free radical polymerization using ammonium persulfate and TEMED as initiators.

[0175]The cross linker can be made with a number of different starting materials: A range of PVAs as well as partially hydrolyzed poly vinyl acetates, 2-hydroxyethyl methacrylates (HEMA) or various other polymers ...

example 3

Demonstration of Sealing in In Vitro Model

[0182]Materials and Methods

[0183]An in vitro model of a TAV implantation shown in FIGS. 15A-15B was constructed using a tube having placed therein a TAV formed of a collapsible mesh 102 securing heart leaflets 104. In the model the mesh 102 did not seat uniformly into the tube, creating a paravalvular leak site 106 between a region of the mesh 102 and the tube 100.

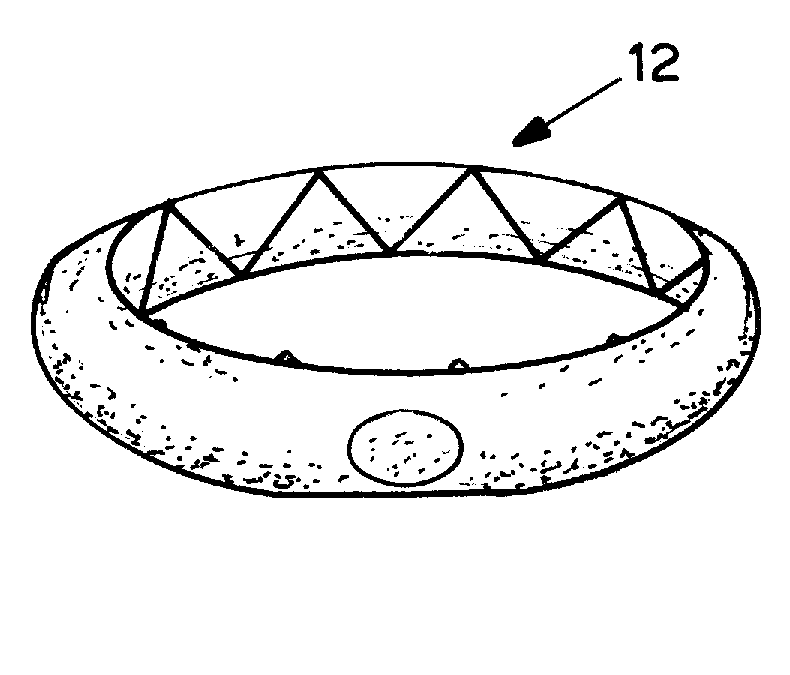

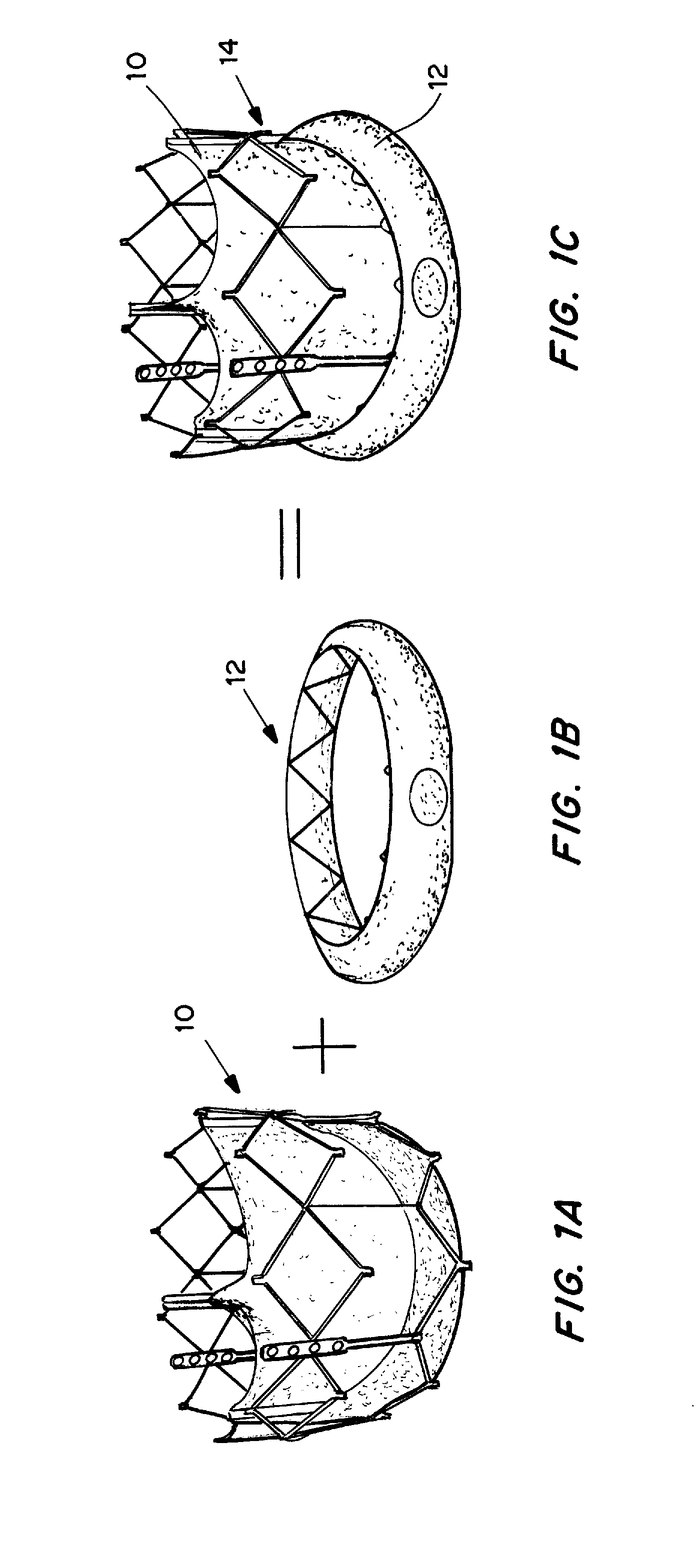

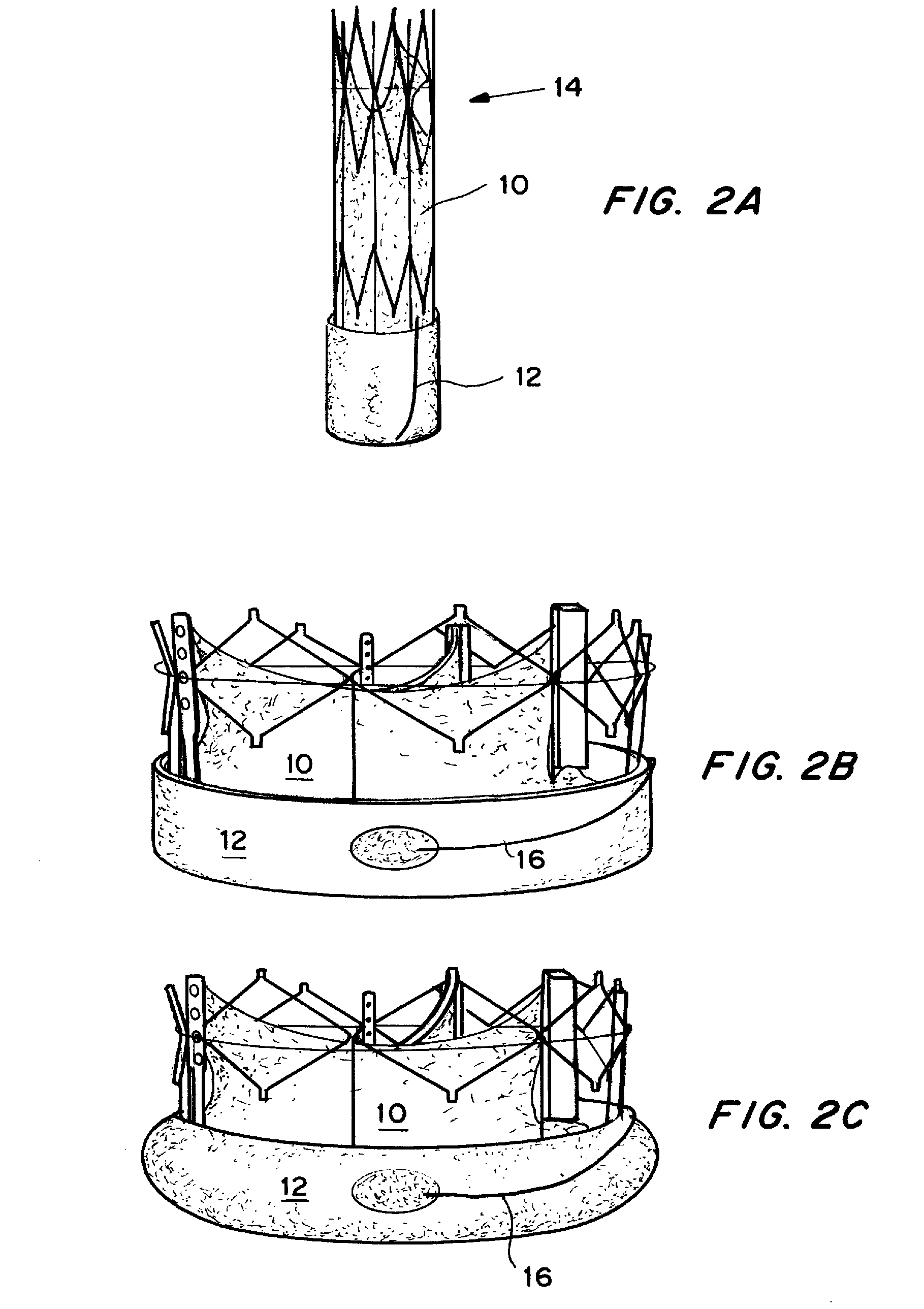

[0184]The TAV includes an expandable seal as described above with reference to FIGS. 2A-2C. The seal 12 was expanded using wire 16 to expose seal 12 to the surrounding fluid (blood), causing the hydrogel to expand and press the seal 12 against the interior of the tube 100, causing the seal 12 membrane to seal the perivalvular leak site 108.

[0185]Results

[0186]FIG. 15A shows a paravalvular leak site 106 due to device inapposition. FIG. 15B shows the leak site is sealed with the seal capsule 108 without disturbing the base geometry of the device. The conformation of the seal happens a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com