Exhaust gas post treatment device

a post-treatment device and exhaust gas technology, which is applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of large space requirement of exhaust gas post-treatment systems, increased distance from internal combustion engines, and individual components upstream from scr, so as to reduce the overall mass, reduce the installation space, and reduce the heat capacity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

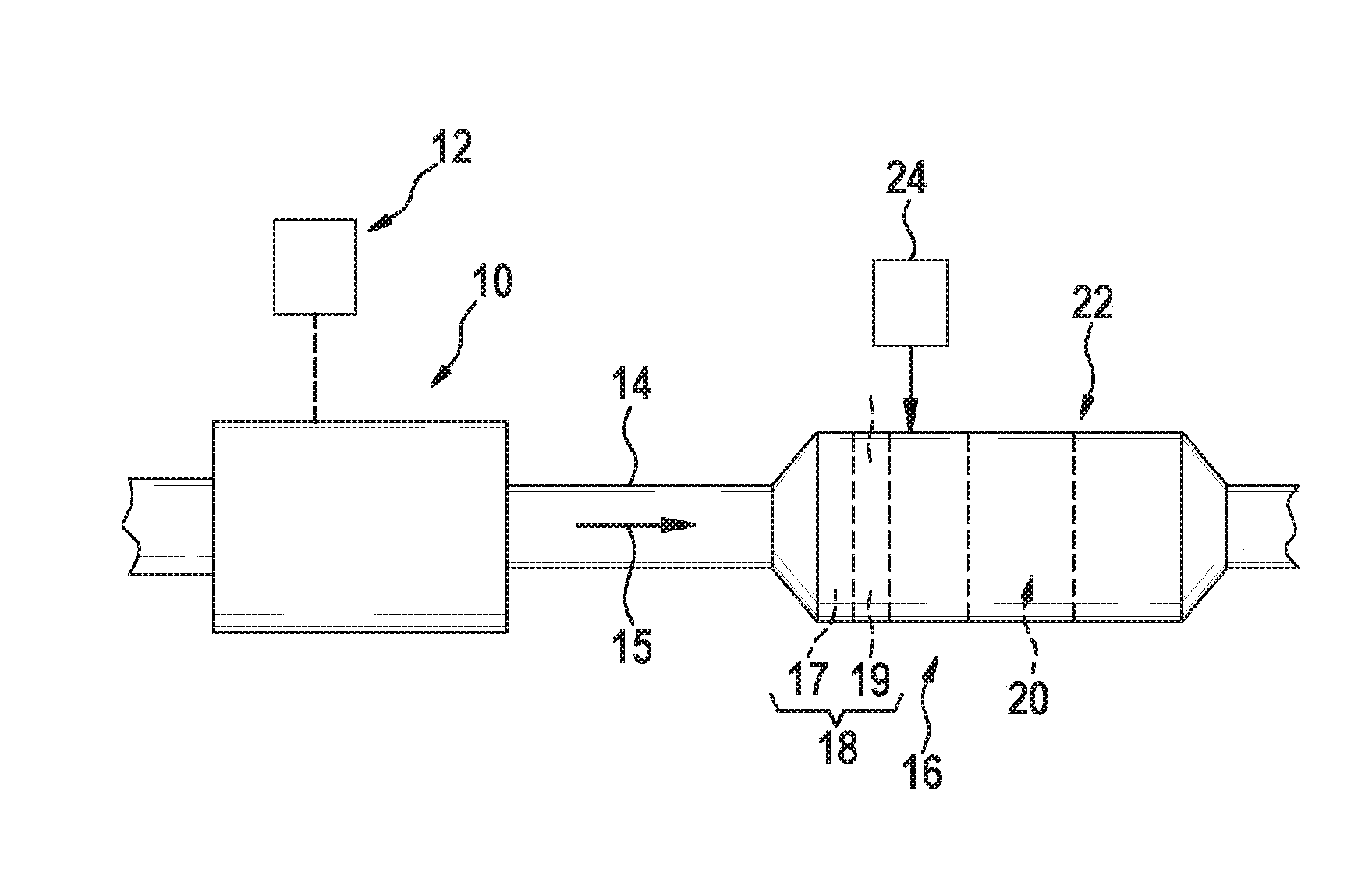

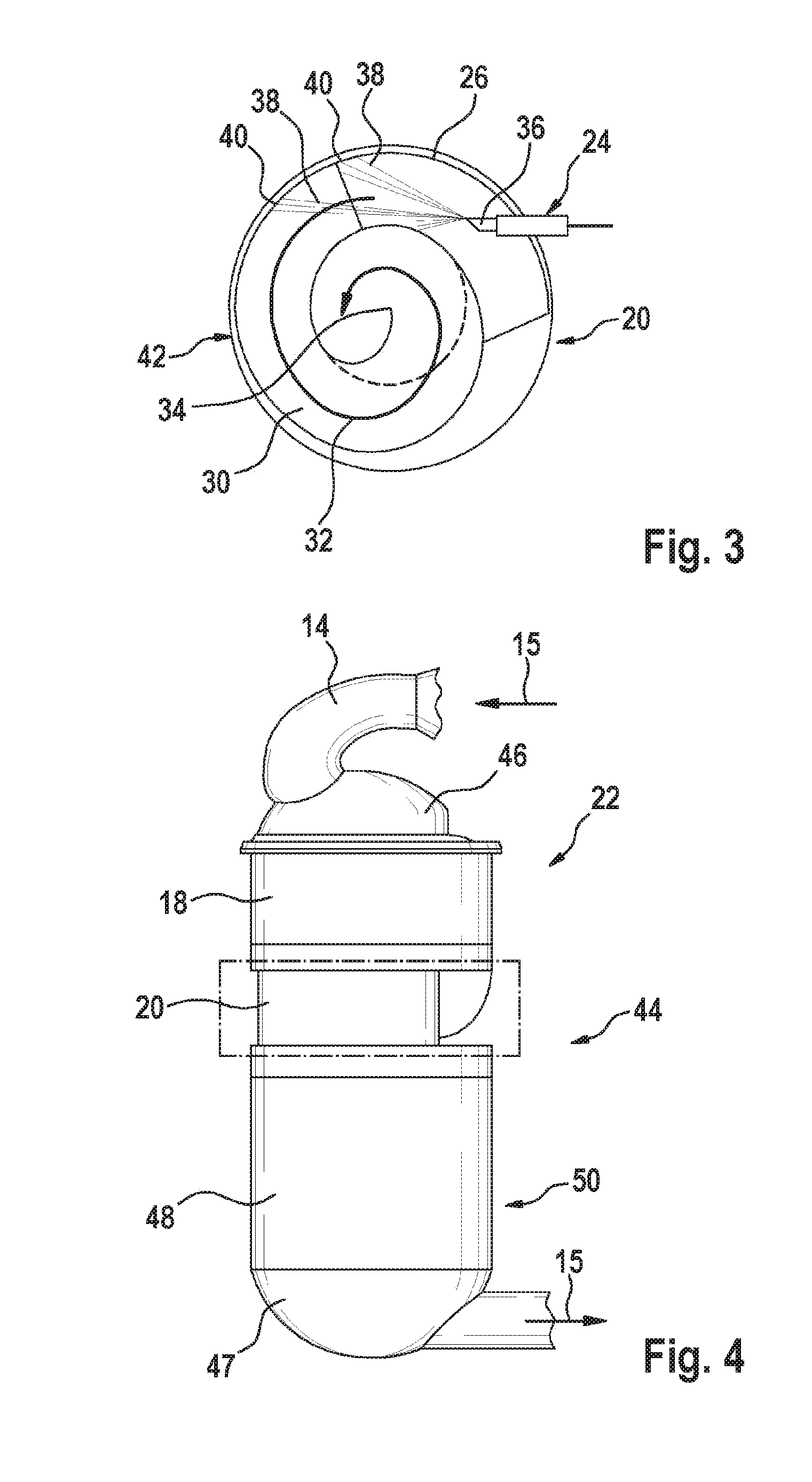

[0040]In FIG. 1, reference character 10 designates an internal combustion engine that is controlled by a (schematically shown) control unit 12 via signal lines. Exhaust gas is conducted away via an exhaust gas train 14 along a flow path 15 in which there is situated an exhaust gas post-treatment system 16. Exhaust gas post-treatment system 16 includes a particle filter 17 (shown only schematically in FIG. 1) and a device having catalytic oxidation function 19, which, combined, can form a particle filter having catalytic oxidation function 18.

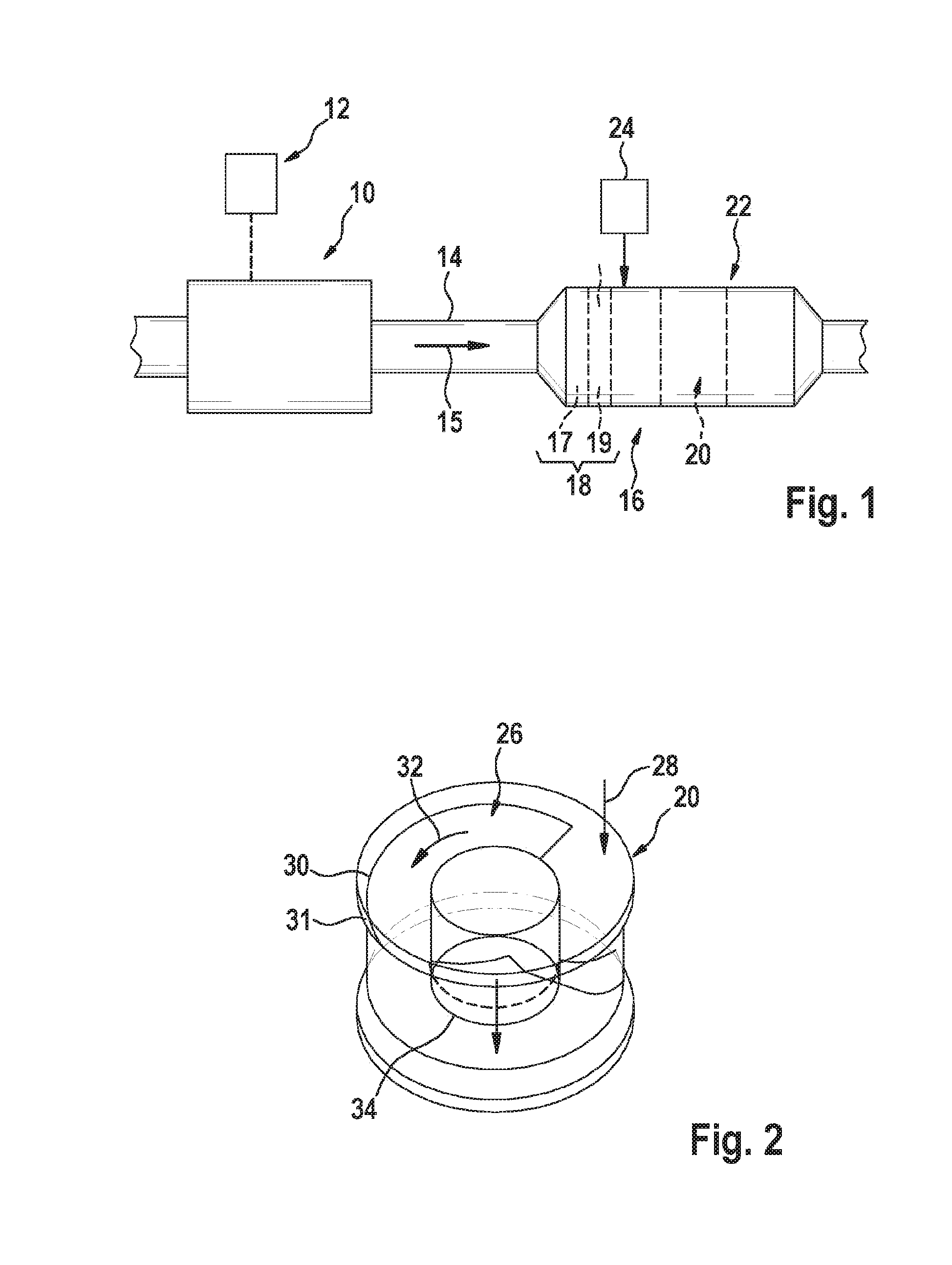

[0041]In addition, at least one mixing chamber 20 is shown, combined with the particle filter having catalytic oxidation function 18 to form a constructive unit 22. With the particle filter having catalytic oxidation function 18, on the one hand particles are filtered out from the exhaust gas flowing in exhaust gas train 14, and a catalytic oxidation function is induced at the catalytic converter integrated in the particle filter having catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com