Low-density interconnected metal foams and methods of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

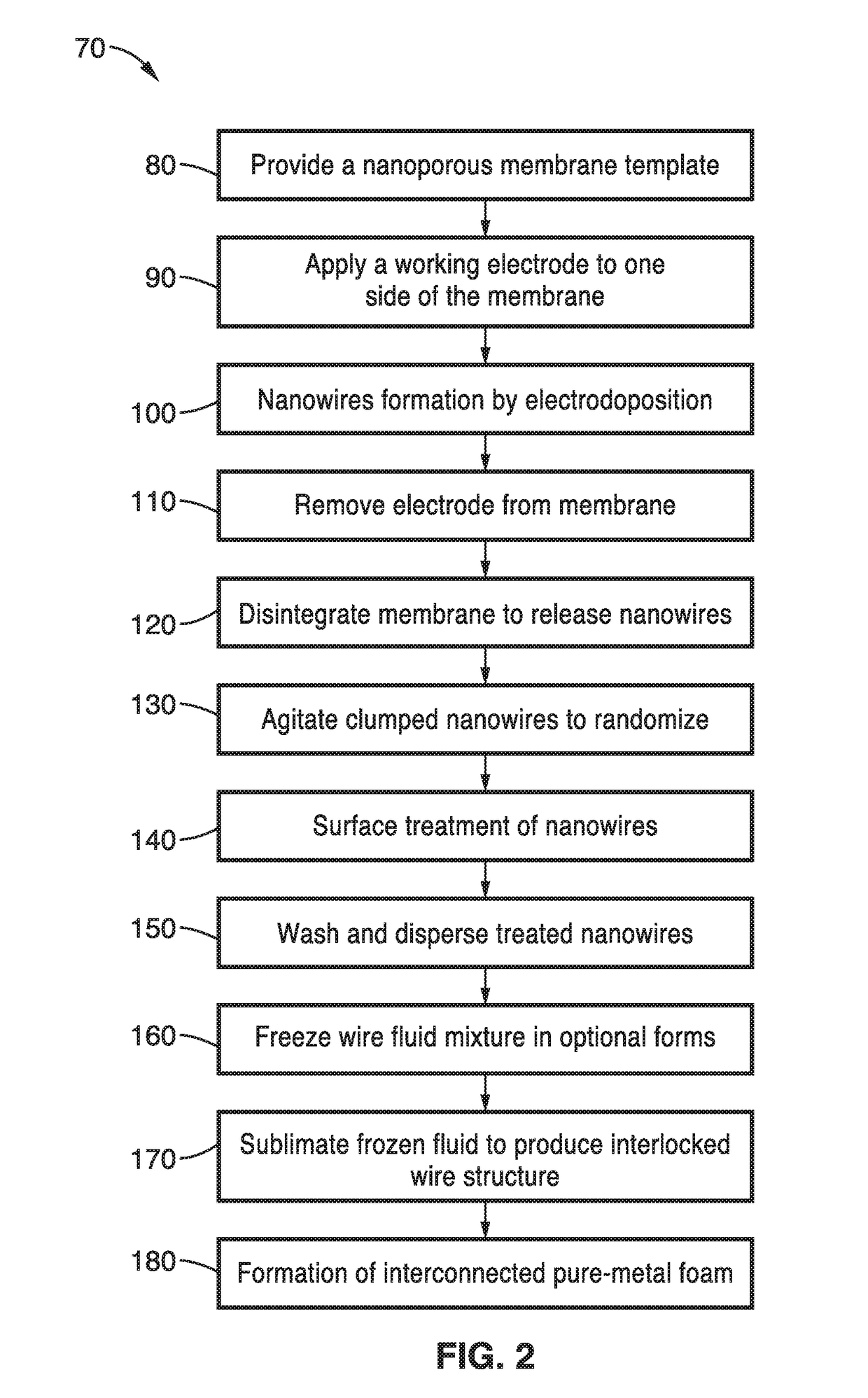

[0068]In order to demonstrate the operational principles of the fabrication methods, several metal foams were prepared using the fabrication method shown schematically in FIG. 2. In this example, pure metal nanowire foams of Cu, Pd, Co and Ag were fabricated with a wide range of tunable densities.

[0069]Nanowires were grown by electrodeposition into nanoporous templates of various sizes and types, including anodized aluminum oxide (AAO) membranes and polycarbonate membranes, to lengths of between 5 μm and 40 μm and diameters from about 50 nm to 200 nm.

[0070]Magnetron sputtering was used to coat thick conductive layers (200 nm to 500 nm) on the backsides of the membranes for use as working electrodes. For copper and cobalt nanowires, a 500 nm thick copper layer was coated onto the backside of the membrane to cover the template pores and to be used as a working electrode during electrodeposition. For silver, palladium, gold and platinum nanowires, a 500 nm gold working electrode was us...

example 2

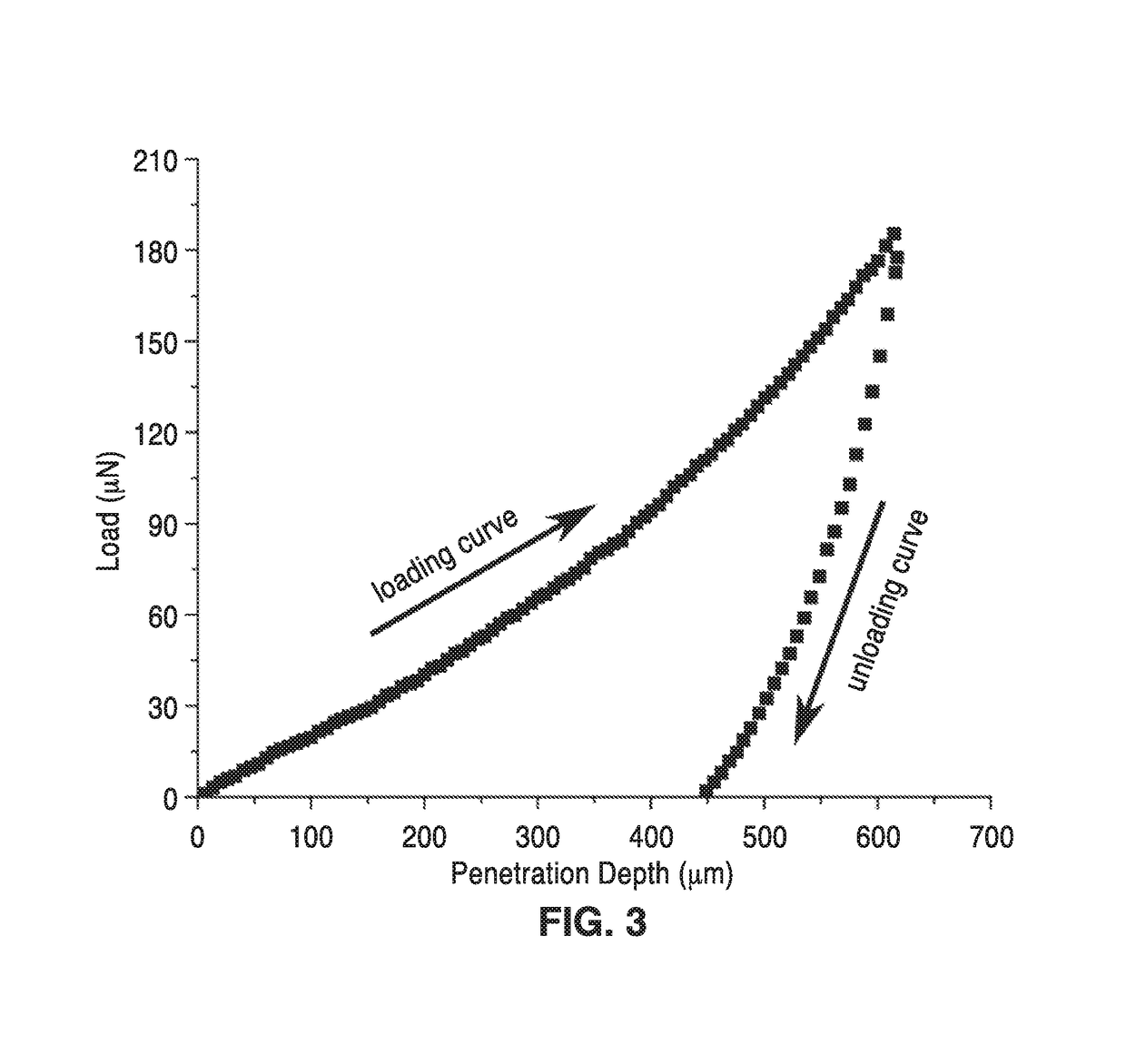

[0079]Nanoindentation experiments were carried out on the foams produced with the methods shown in Example 1 to quantify the enhanced strength of the interconnected Cu nanowire foams. In order to perform nanoindentation measurements, cylindrical Cu foams with a 2 mm height and diameter were fabricated and strengthened using the oxidation / reduction process. The final foams ranged in densities from 8 mg / cm3 to 70 mg / cm3. The indenter tip was a 2 mm ruby sphere and measurements were conducted at room temperature and ambient laboratory humidity. The loading and unloading rate was kept constant at 100 μm / m. A sample loading / unloading curve is shown in FIG. 3.

[0080]Loading / unloading curves were derived for a 9 mg / cm3 strengthened Cu cylindrical foam with 2 mm in height and diameter. By measuring the initial slope of the unloading curve it was possible to extract the modulus of the subject material. The elastic modulus of each sample was extracted from the initial slope of the unloading cu...

example 3

[0085]One potential use of ultralow density metal foams is for use as high energy density laser targets due to their ability to be heated volumetrically that allows targets composed of high-Z elements to uniformly reach the extreme temperatures that are required for X-ray emission. Gas targets, oxides, metal-doped aerogels and metal-lined cavities have been employed previously for reaching the necessary effective density. However, the pure metal targets allow higher X-ray conversion efficiencies if the targets can be fabricated at densities low enough to allow volumetric heating while still maintaining mechanical stability.

[0086]To demonstrate the functionality of pure metal foam targets produced by the methods, spherical Cu targets (2 mm and 4 mm diameters) and cylindrical Ag targets (4 mm diameter and length) were produced to be used as targets for testing at the OMEGA and the National Ignition Facility (NIF) laser facilities. The enhanced mechanical strength was critical to the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com