Feedstock and heterogeneous structure for tough rare earth permanent magnets and production process therefor

a rare earth permanent magnet and heterogeneous structure technology, applied in the field of particle feedstocks and rare earth permanent magnets, can solve the problems of high mechanical failure risk of repms when subjected to mechanical stress, sintered magnets are quite brittle, easy to crack or fracture, and the machining techniques of these magnets are limited to grinding. , to achieve the effect of increasing mechanical toughness, high magnetic performance and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

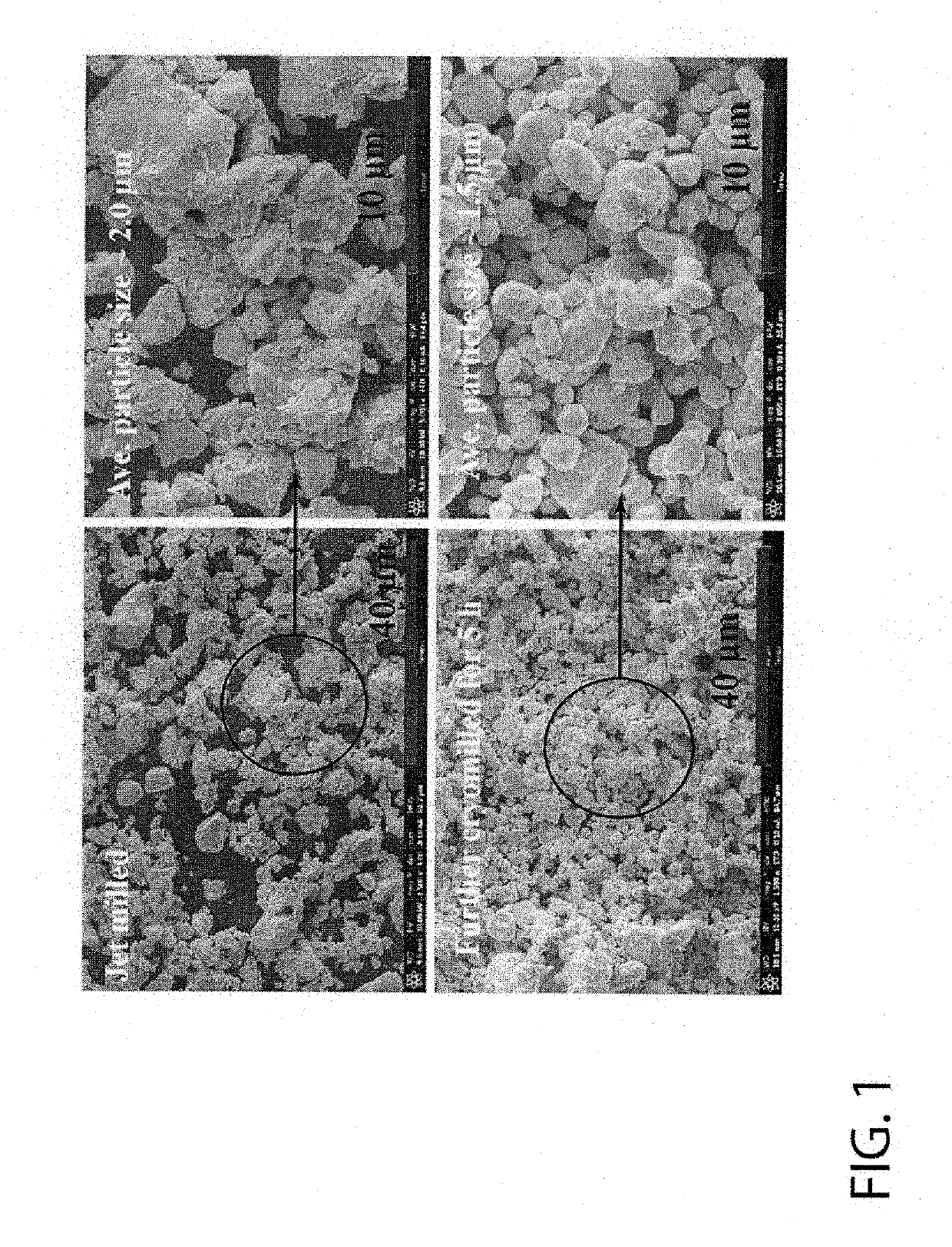

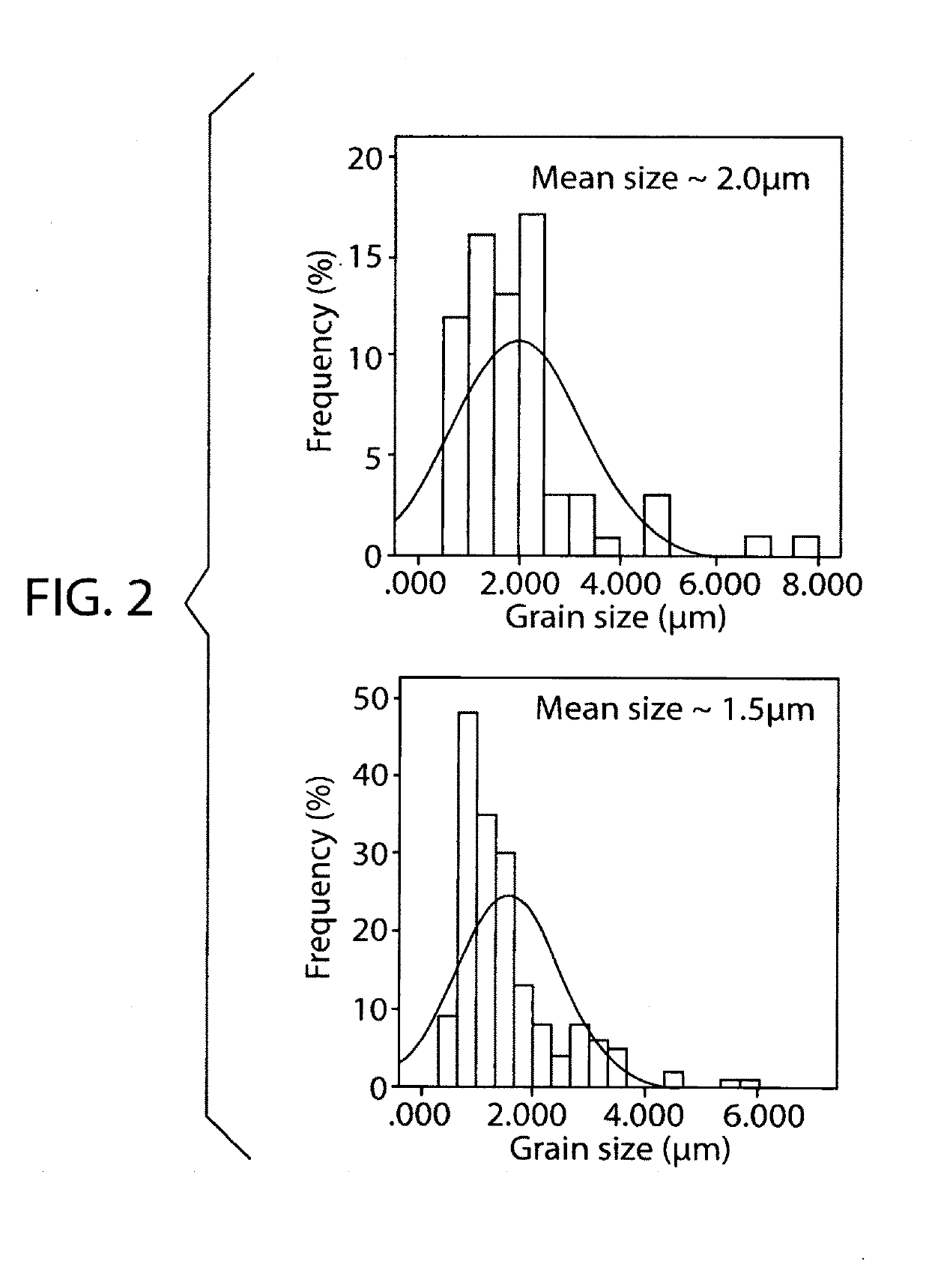

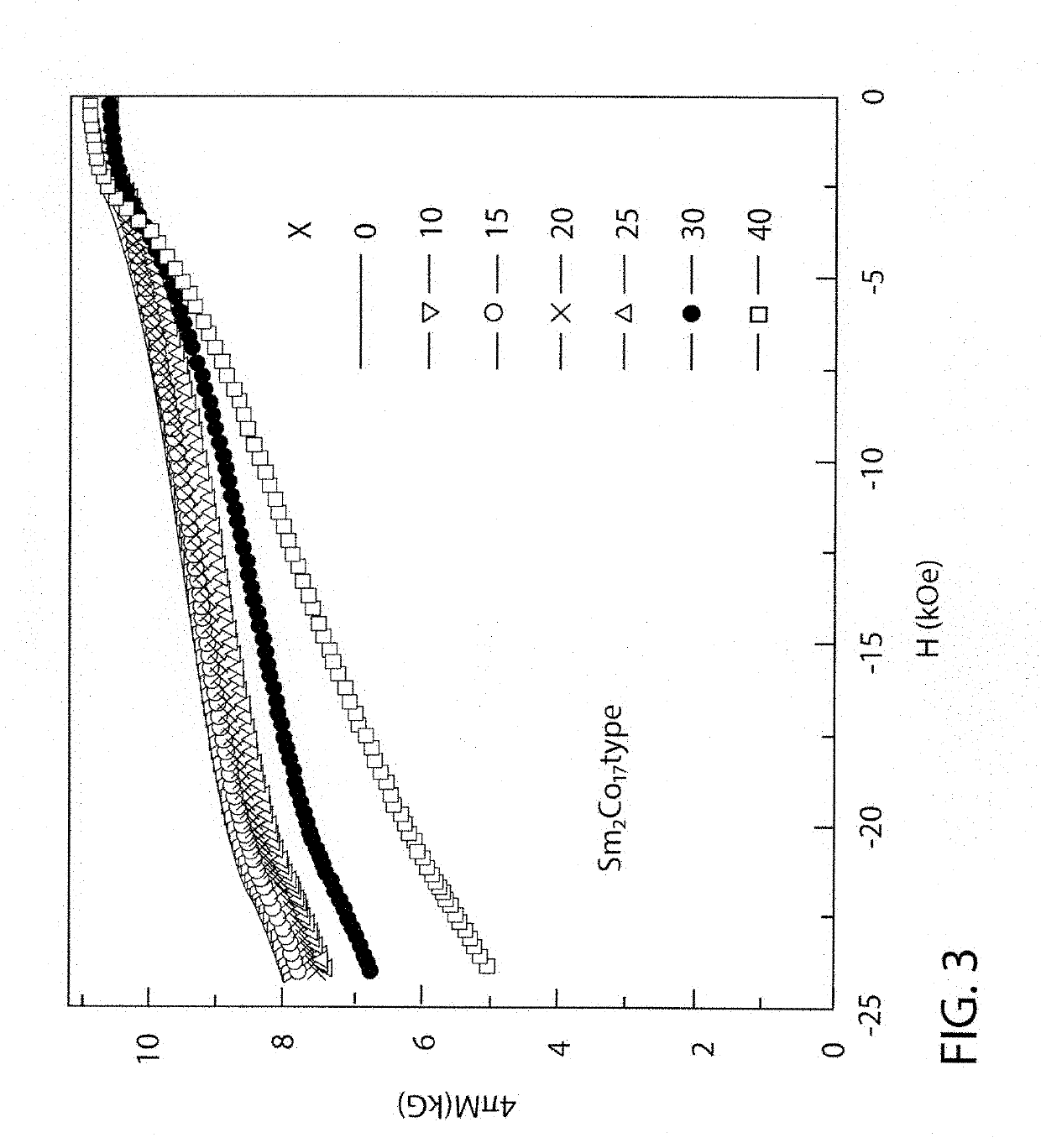

[0038]The present invention relates to rare earth permanent magnets (REPMs) having a heterogeneous microstructure and their production in a manner to provide significantly enhanced toughness; i.e. resistance-to-fracture as evidenced by enhanced mechanical toughness property such as flexural strength and / or fracture toughness, while maintaining or with a minimum sacrifice in the hard magnetic properties. The REPMs made pursuant to embodiments of the invention have heterogeneous grain microstructures, such as bi-modal, tri-modal, multi-modal, laminated, gridded, or gradient coarse / fine grain structures, or other microstructural heterogeneity, etc., without the need for changing the chemical compositions of magnets. To increase flexural strength and / or fracture toughness of the REPMs, particle sizes or grain sizes of the particle feedstock are modified with fixed chemical feedstock compositions in this invention. For purposes of illustration and not limitation the typical feedstock com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| blending time | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com