Method for preparing tricarbonyl technetium-99m intermediate

a tricarbonyl intermediate and tricarbonyl technology, applied in the field of tricarbonyl tricarbonyl intermediate preparation, can solve the problems of affecting the clinical application of the above-mentioned methods, affecting the clinical application of the hospital, and the routine application of the clinical practice is not feasible, so as to achieve easy operation, high labeling yield, and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

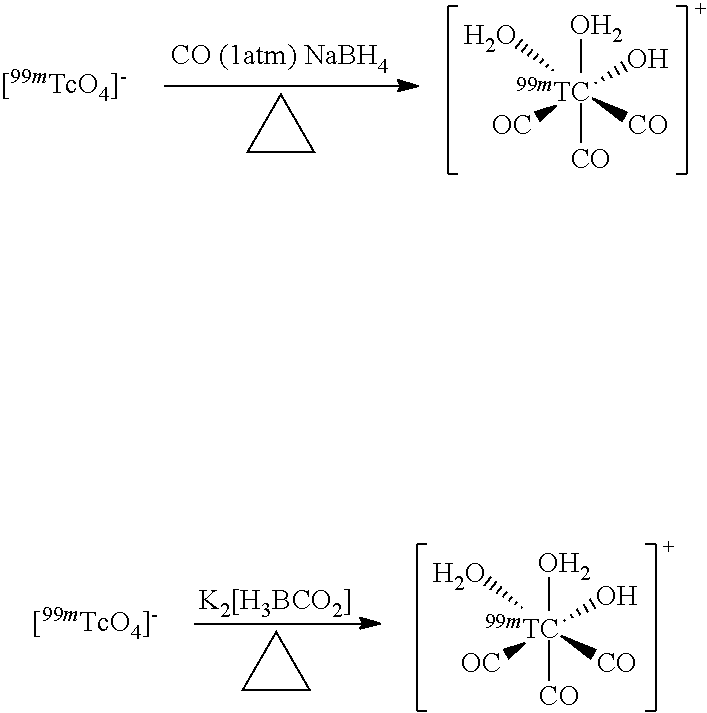

[0068]The technetium tricarbonyl intermediate was prepared by using cyclopentadienyl manganese tricarbonyl as the carbon monoxide source and sodium borohydride as the reducing agent.

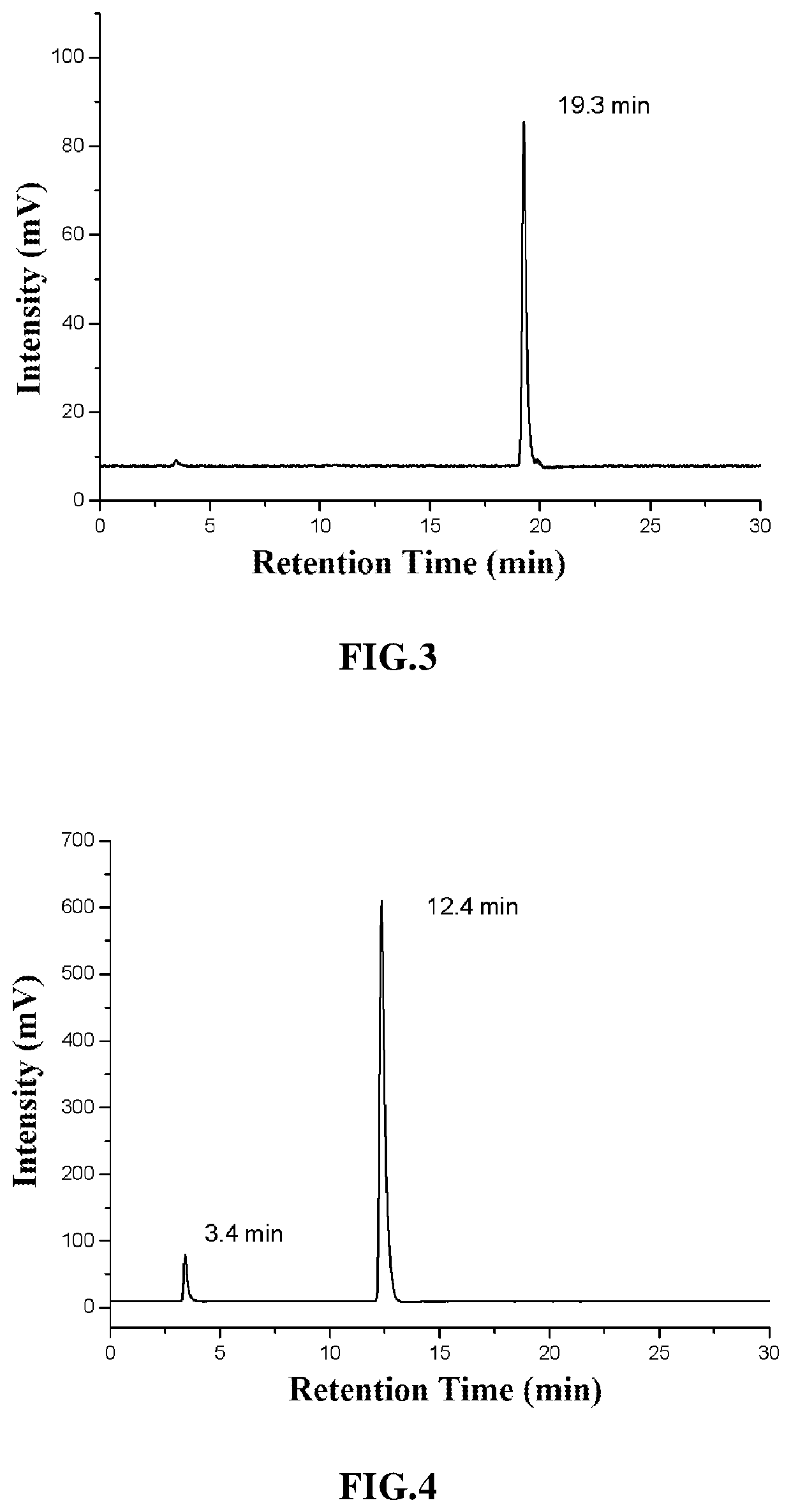

[0069]200 mg of cyclopentadienyl manganese tricarbonyl, 10 mg of sodium borohydride, 20 mg of potassium sodium tartrate, and 4 mg of sodium carbonate were weighed and added to a quartz bottle before the addition of 1 mL (37 MBq) freshly prepared 99mTcO4− eluent. After being shaken greatly, the quartz bottle was sealed and placed under a hand-held UV lamp (254 nm) with a reaction proceeding for 20 min at room temperature. After the reaction, the mixture obtained was adjusted to a pH of 6 to 7 by 0.1 mol / L hydrochloric acid and filtered by a syringe to obtain the product technetium tricarbonyl intermediate [99mTc(H2O)3(CO)3]+. HPLC analysis revealed the product peak with a retention time of 9.2 min and a labeling yield of 96%.

example 2

[0070]The technetium tricarbonyl intermediate was prepared by using methyl cyclopentadienyl manganese tricarbonyl as the carbon monoxide source and sodium borohydride as the reducing agent.

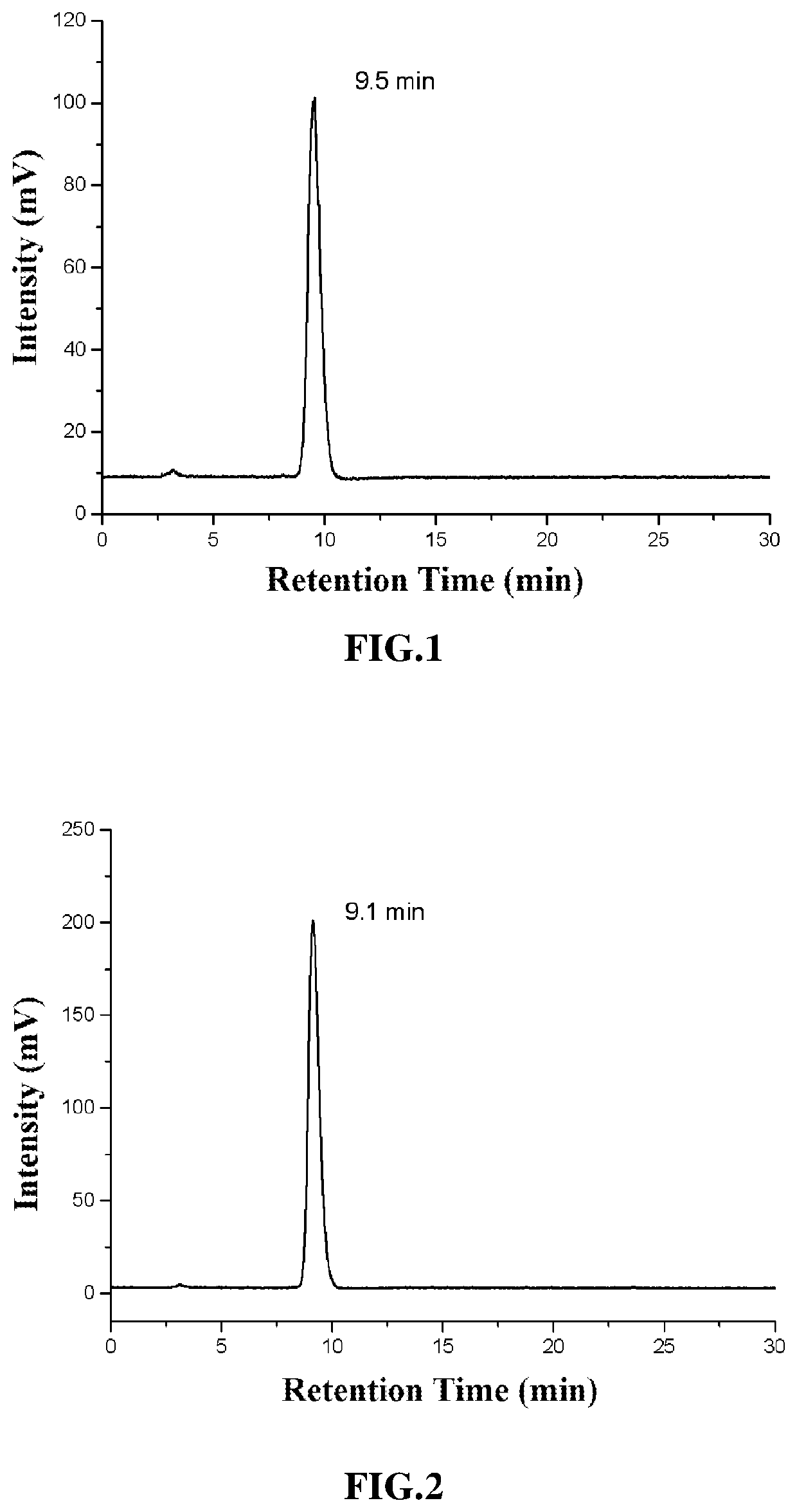

[0071]20 mg of methyl cyclopentadienyl manganese tricarbonyl, 5.5 mg of sodium borohydride, 20 mg of potassium sodium tartrate, and 4 mg of sodium carbonate were weighed and added to a penicillin bottle before the addition of 1 mL (37 MBq) freshly prepared 99mTcO4− eluent. After being shaken greatly, the penicillin bottle was sealed and placed under a hand-held UV lamp (365 nm) with a reaction proceeding for 20 min at room temperature. After the reaction, the mixture obtained was adjusted to a pH of 6 to 7 by 0.1 mol / L hydrochloric acid and filtered by a syringe to obtain the product technetium tricarbonyl intermediate [99mTc(H2O)3(CO)3]+. HPLC analysis revealed the product peak with a retention time of 9.5 min and a labeling yield of 98%, and the chromatograms was shown in FIG. 1.

example 3

Preparation of Cyclopentadienecarboxylic Acid Manganese Tricarbonyl

[0072]

[0073]1 g of cyclopentadienyl manganese tricarbonyl was weighed and dissolved in 10 mL anhydrous tetrahydrofuran. A solution of N-butyl lithium in hexane (3.37 mL, 1.6 mol / L) was dropwise added to the tetrahydrofuran solution under the protection of −45° C. argon. After the dropwise addition, excess dry ice was added to obtain a mixture which was stirred at room temperature for 2 h. After the reaction, the solvent was evaporated under reduced pressure, and then water and ethyl acetate were added to the mixture obtained with being shaken greatly. Hydrochloric acid was added to the water phase to produce precipitate which was collected and dried obtaining 0.76 g yellow powder (cyclopentadienecarboxylic acid manganese tricarbonyl) with a yield of 62.5%.

Preparation of the Technetium Tricarbonyl Intermediate [99mTc(H2O)3(CO)3]+

[0074]The technetium tricarbonyl intermediate was prepared by using cyclopentadienecarboxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com