Organic antimicrobial textile

a textile and antimicrobial technology, applied in the field of organic antimicrobial textiles, can solve the problems of inability to easily degrade in the environment, microbial strains forming, and continuous contamination of the environment with these disinfectants, and achieve the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

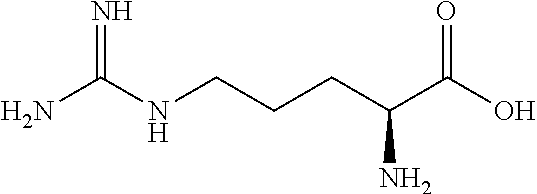

extile Treated with L-Arginine

[0177]A 100% viscose textile was treated with L-arginine in a two-cycle process, comprising in the main liquor application cycle an exhaustion process, and in the secondary process cycle a padding process.

[0178]A liquor for both the exhaust and the padding processes was prepared containing 30 or 40 grams L-arginine per liter (gpl). The pH was adjusted to pH 4.5 using citric acid. The liquor was stirred at 70° C. for 1 hour.

[0179]The exhaustion process was carried out with a wet pickup of about 100%, resulting in an on-weight-fabric L-arginine add-on of 3.0 / 4.0%. Exhaustion was performed with the undiluted liquor for 1 hour at 60° C., followed by drying at 120° C.

[0180]Padding was performed with an L-arginine concentration of 10 gpl in the liquor. The padding pickup rate was about 65%. Thus, the total amount of L-arginine added to the textile in the exhaust and padding processes together can be estimated to be 3.0 / 4.0%+0.65%=3.65 / 4.65% o.w.f.

[0181]After ...

example 2

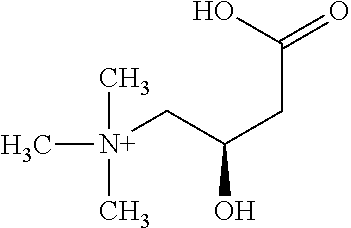

extiles Treated with L-Carnitine

[0198]A 100% viscose textile was treated with L-carnitine in a two-cycle process, the main process cycle comprising an exhaust process and the secondary process cycle comprising a padding process.

[0199]A liquor was prepared by dissolving in water 40 gpl L-carnitine provided as powder, and adjusting the pH to pH 4.5 with citric acid. The liquor was stirred for 30 minutes at 60° C. before being applied to the textile samples by means of exhaustion, followed by drying at 120° C., and padding.

[0200]The exhaustion process was carried out with a wet pickup of about 100%, resulting in an on-weight-fabric L-carnitine add-on of 4.0%. The padding pickup rate was about 65%. Thus, the total amount of L-carnitine added to the textile in the exhaust and padding processes together can be estimated to be 4.0%+2.6%=6.6% o.w.f.

[0201]After padding, the textile was dried at 120° C. and cured at 180° C. for 2 minutes. After curing, one treated sample was tested directly f...

example 3

extiles Treated with Combinations of L-Arginine and Chitosan

[0204]A 100% viscose textile was treated with chitosan or with L-arginine and chitosan in a two-cycle process, comprising in the main liquor application cycle an exhaust step, and in the secondary process cycle a padding step.

[0205]A liquor for the exhaustion step was prepared containing 40 grams chitosan stock solution (8%) per liter or 40 grams of chitosan stock solution and 60 grams of L-arginine per liter. The pH was adjusted to pH 4.5 using citric acid or acetic acid. The liquor was stirred at 70° C. for 1 hour. The exhaustion process was carried out with a wet pickup of about 100%, resulting in a chitosan add-on of 0.32% o.w.f. and an L-arginine add-on (where applicable) of 6% o.w.f. Exhaustion was performed for 1 hour at 60° C., followed by drying at 120° C.

[0206]The liquor used in the padding process contained 10 grams chitosan stock solution (8%) per liter or 10 grams of chitosan stock solution and 30 grams of L-ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com