Manufacturing method of polarizing property electrode for electrical double layer capacitor, and manufacturing method of electrode sheet for electrical double layer capacitor

a manufacturing method and technology for capacitors, applied in capacitor electrodes, electrolytic capacitors, liquid electrolytic capacitors, etc., can solve the problem that the above organic chemical compound scattering object (evaporated object) cannot easily stay in the atmosphere, and achieve the effect of reducing increasing the diffusion resistance between the activated carbon powder and the electrolyte, and being difficult to remov

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(First Embodiment)

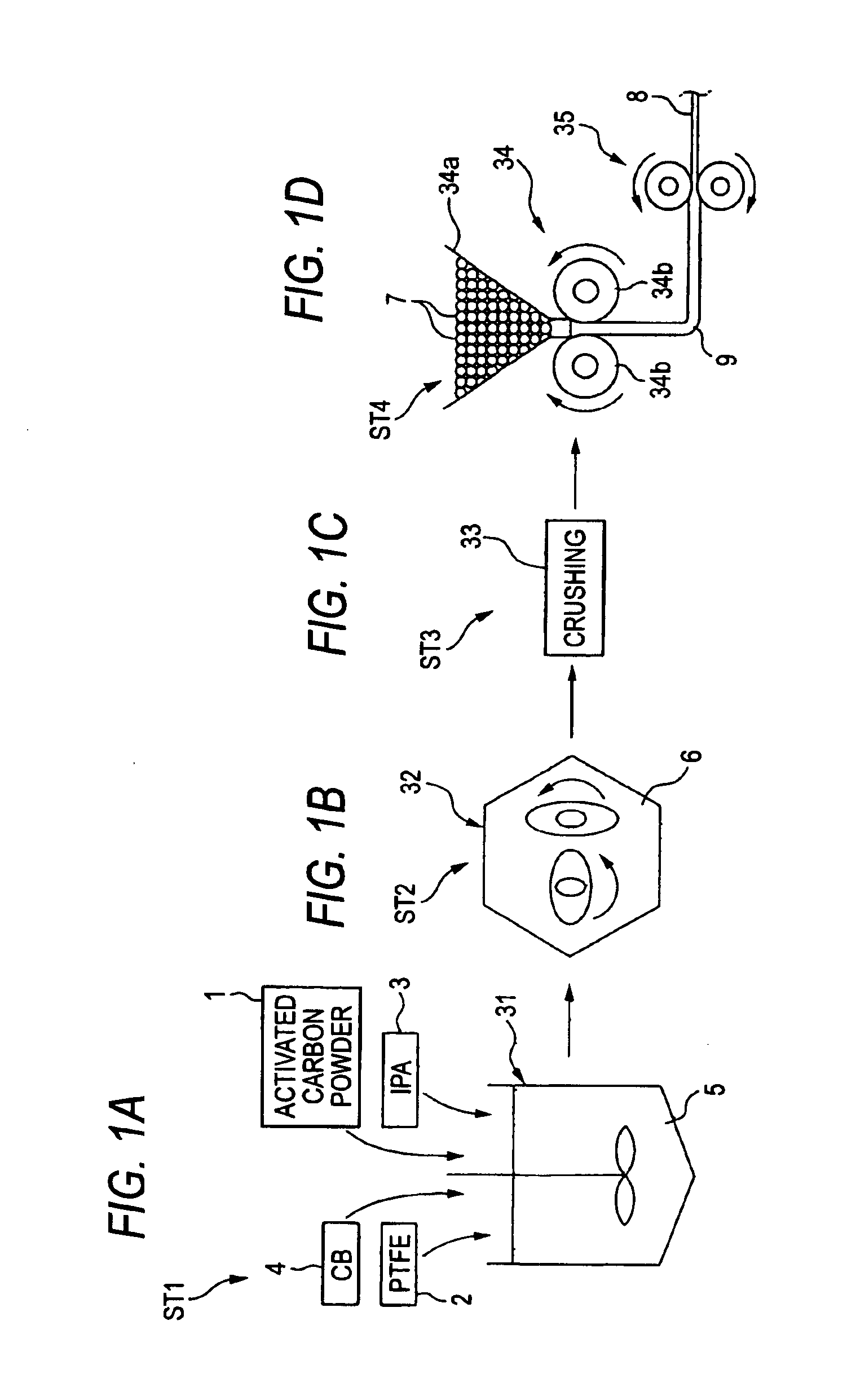

(Manufacture of Electrical Double Layer Capacitor of Embodiment 1)

First, the activated carbon powder is manufactured as follows. First, carbonization processing is performed by holding phenol resin within a nitrogen atmosphere at 900° C. for two hours. Next, when the obtained raw material carbon is again raised in temperature within the nitrogen current and reached 800° C., a nitrogen mixing gas including water vapor at 5% and carbon dioxide at 5% is circulated and held at 900° C. for two hours so that activation processing is performed. The obtained activated carbon is crushed by a ball mill crusher until the activated carbon had an average grain diameter of about 2 to 15 μm, and is set to activated carbon powder.

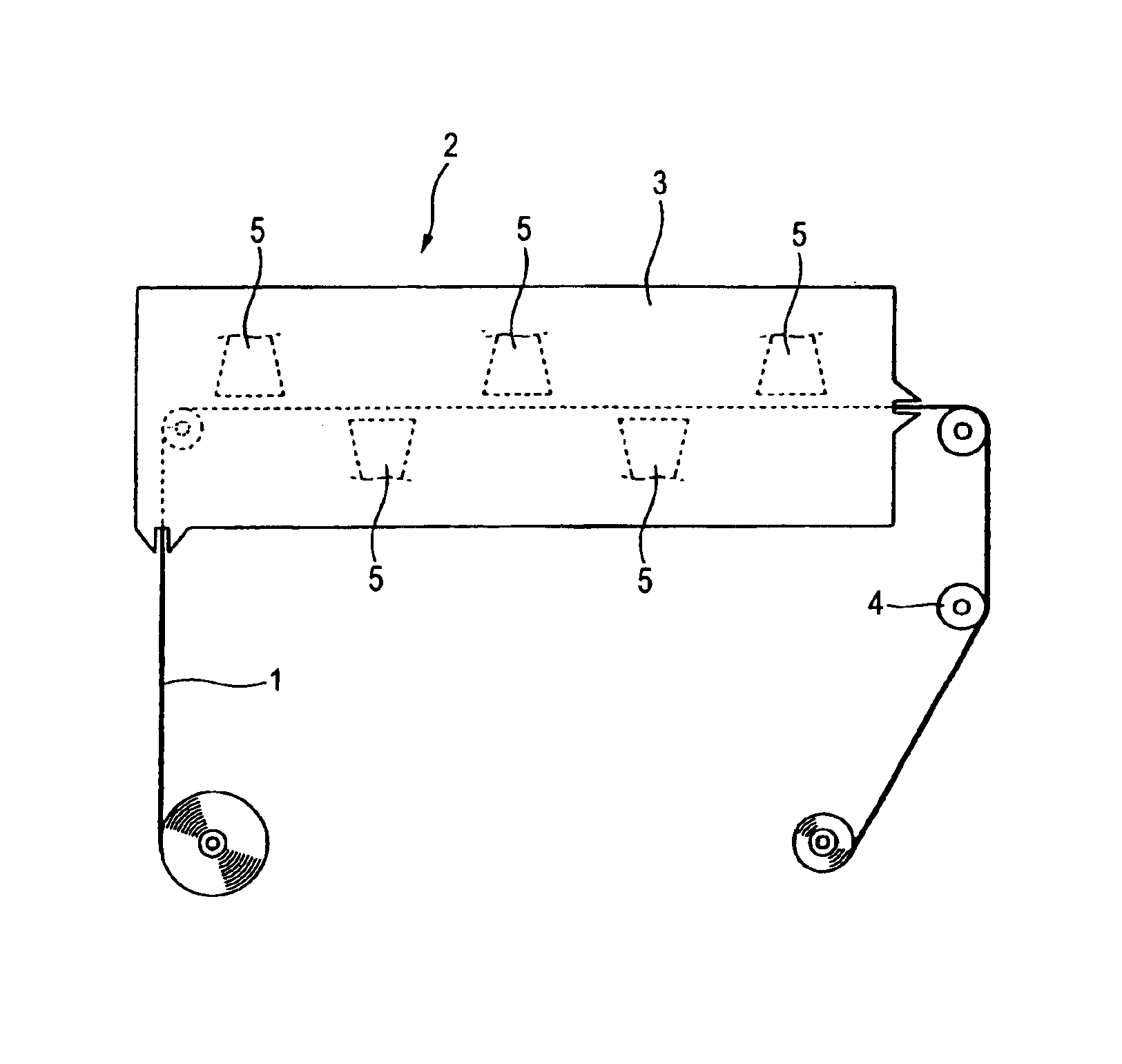

Next, an electrode molding process for kneading and molding the obtained activated carbon powder, a binding material (polytetrafluoroethylene) and an organic solvent for lubrication (isopropyl alcohol (IPA)) in a sheet shape is performed. Namely, 8 parts ...

second embodiment

(Second Embodiment)

(Manufacture of Electrical Double Layer Capacitor of Embodiment 2)

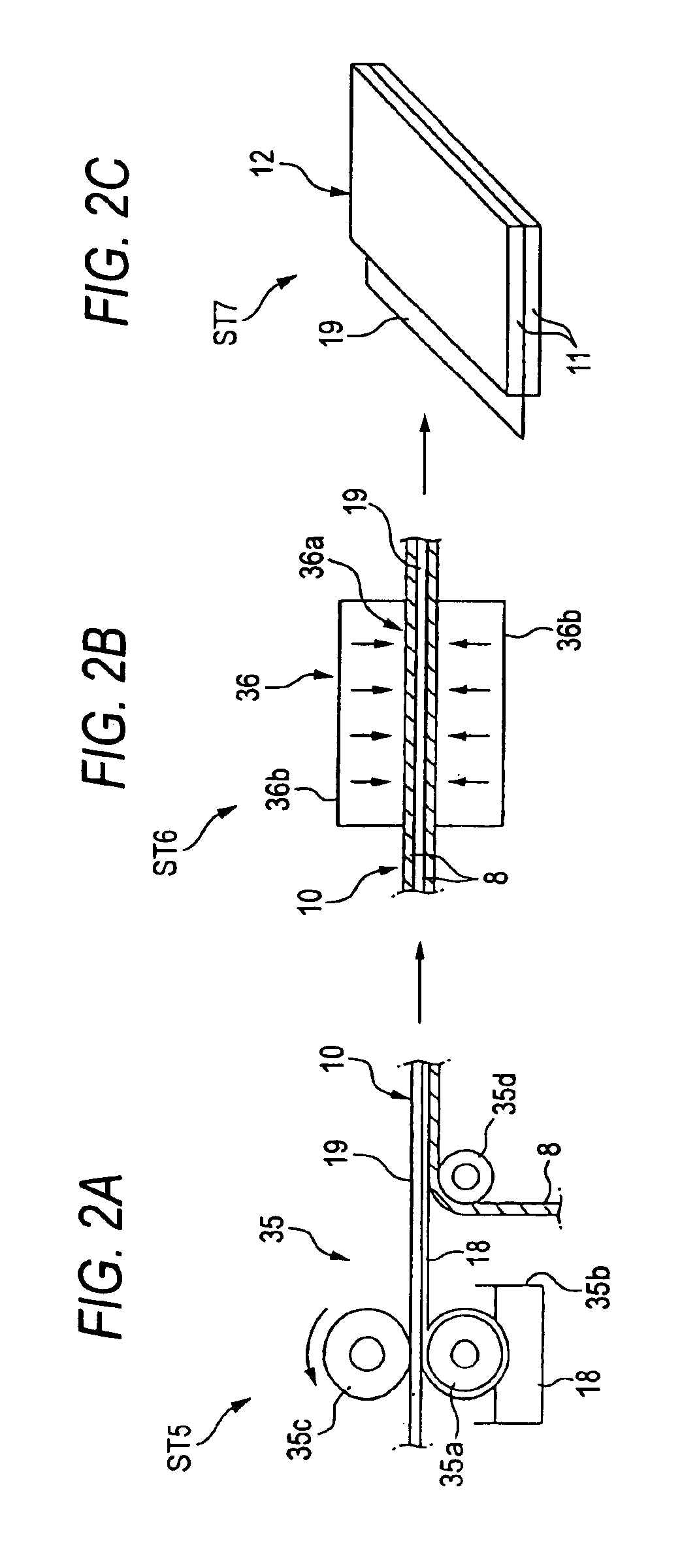

Similar to the case of the above Embodiment 1, the electrical double layer capacitor of Embodiment 2 is manufactured except that the electrode body sheet after the current collecting body adhering process is introduced into the continuous drying furnace of a hot air type, and the continuous drying (continuous drying process) is performed in the condition of blowing the hot air of 150° C. in temperature for four minutes at a flow rate of 10 L / minute, and the drying time in the vacuum drying process is set to 48 hours.

(Analysis of Organic Chemical Compound Amount Within Polarizing Property Electrode)

With respect to the Embodiment 2 and the Comparison Example 2 made in the above First Embodiment, one portion of the polarizing property electrode after the vacuum drying process is picked and heated for 60 minutes at 300° C. within a nitrogen gas current so that moisture within the electrode is set to wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| grain diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com