Methods of treating Syndrome X with aliphatic polyamines

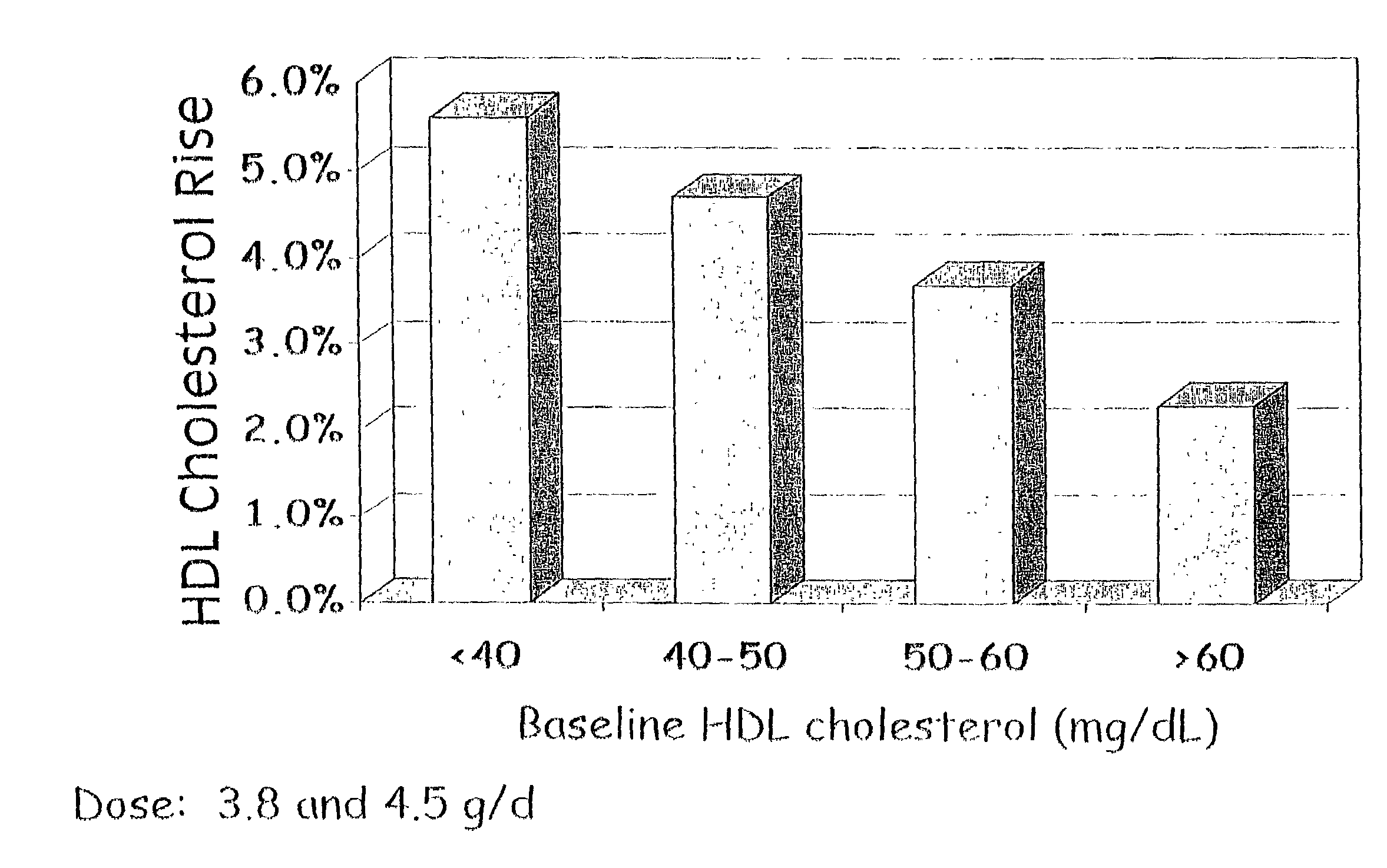

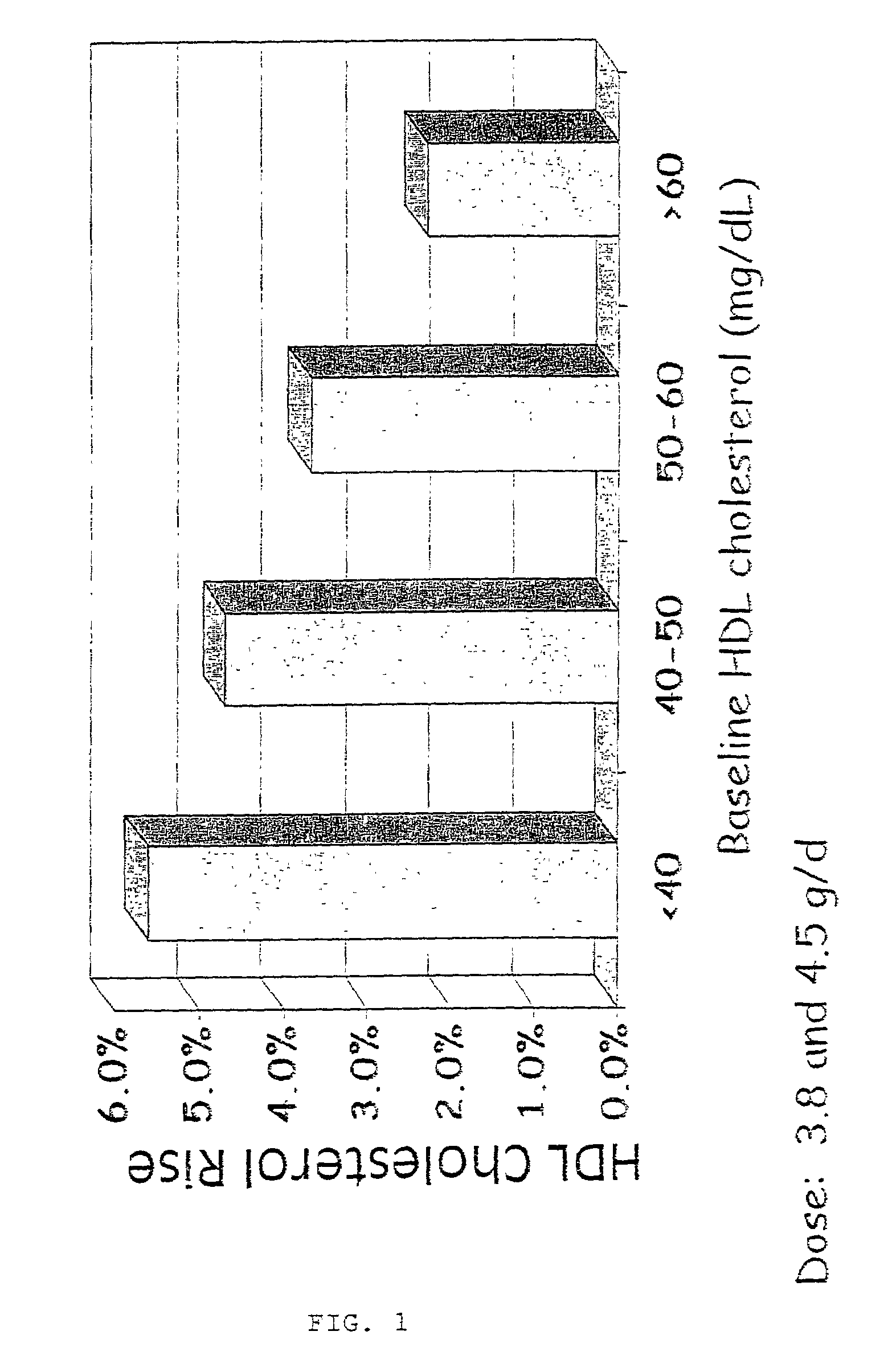

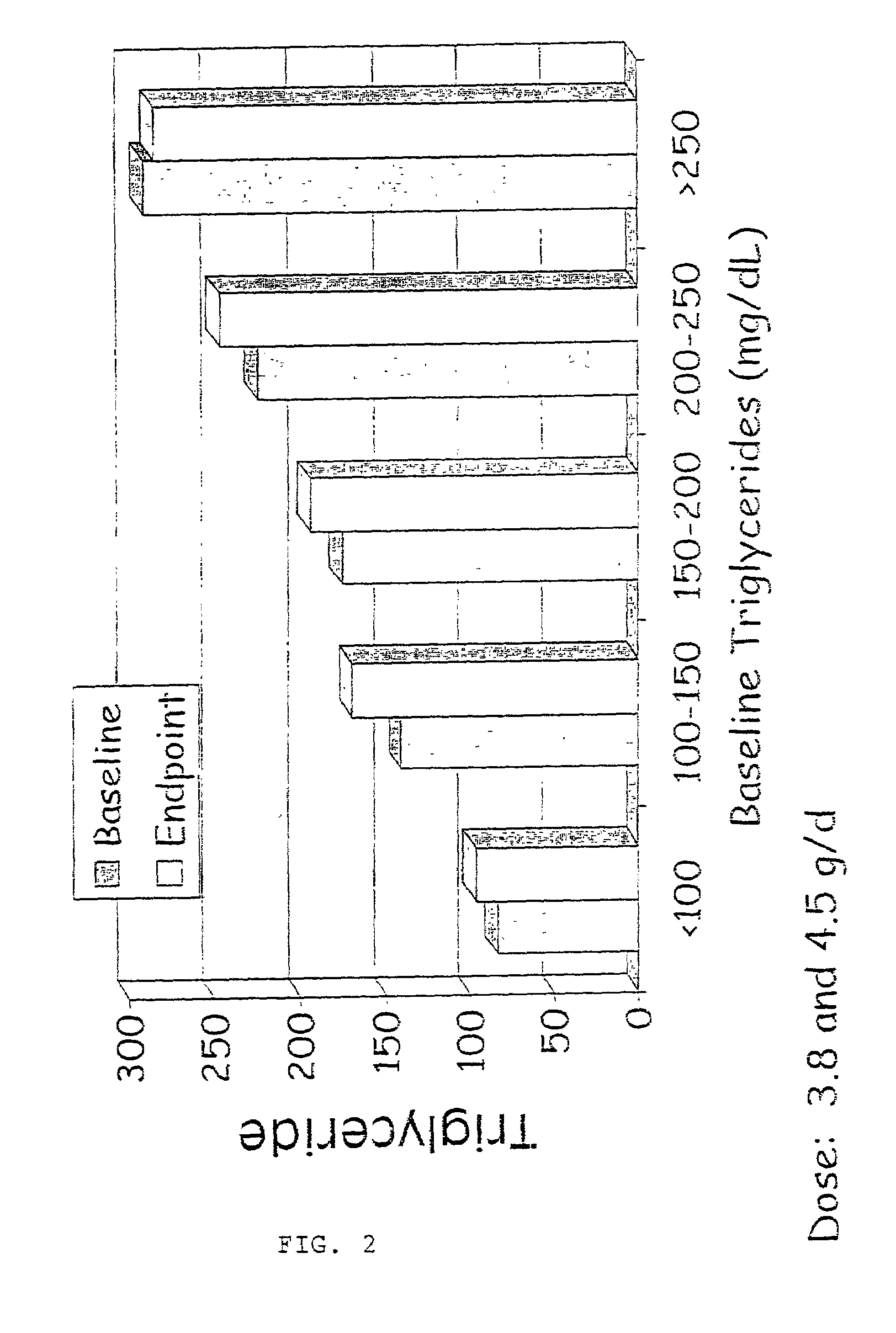

a technology of aliphatic polyamine and syndrome x, which is applied in the direction of antinoxious agents, extracellular fluid disorders, metabolic disorders, etc., can solve the problems of increased risk of peripheral vascular and coronary artery disease in individuals with syndrome x, and achieve the effects of improving the symptoms of patients, reducing the ldl level, and raising the plasma level of high density lipoprotein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Poly(allylamine) Hydrochloride

[0082]To a 2 liter, water-jacketed reaction kettle equipped with (1) a condenser topped with a nitrogen gas inlet, (2) a thermometer, and (3) a mechanical stirrer was added concentrated hydrochloric acid (360 mL). The acid was cooled to 5° C. using circulating water in the jacket of the reaction kettle (water temperature=0° C.). Allylamine (328.5 mL, 250 g) was added dropwise with stirring while maintaining the reaction temperature between about 5° C. and about 10° C. After addition was complete, the mixture was removed, placed in a 3 liter one-neck flask, and 206 g of liquid was removed by rotary vacuum evaporation at 60° C. Water (20 mL) was then added and the liquid was returned to the reaction kettle. Azobis(amidinopropane) dihydrochloride (0.5 g) suspended in 11 mL of water was then added. The resulting reaction mixture was heated to about 50° C. under a nitrogen atmosphere with stirring for 24 hours. Additional azobis(amidinopropane...

example 2

Preparation of Poly(allylamine) Hydrochloride Cross-linked with Epichlorohydrin

[0084]To a 5 gallon vessel was added poly(allylamine) hydrochloride prepared as described in Example 1 (1 kg) and water (4 L). The mixture was stirred to dissolve the hydrochloride and the pH was adjusted by adding solid NaOH (284 g). The resulting solution was cooled to room temperature, after which epichlorohydrin cross-linking agent (50 mL) was added all at once with stirring. The resulting mixture was stirred gently until it gelled (about 35 minutes). The cross-linking reaction was allowed to proceed for an additional 18 hours at room temperature, after which the polymer gel was removed and placed in portions in a blender with a total of 10 L of water. Each portion was blended gently for about 3 minutes to form coarse particles which were then stirred for 1 hour and collected by filtration. The solid was rinsed three times by suspending it in water (10 L, 15 L, 20 L), stirring each suspension for 1 ho...

example 3

Alkylation of Poly(allylamine) Cross-linked with epichlorohydrin with (6-Bromohexyl)trimethylammonium bromide and 1-bromodecane alkylating Agent

[0085]To a 12-1 round bottom flask equipped with a mechanical stirrer, a thermometer, and a condenser was added methanol (5 L) and sodium hydroxide (133.7 g). The mixture was stirred until the solid dissolved. Cross-linked poly(allylamine) (297 g, ground to −80 mesh size) was added along with additional methanol (3 L). (6-Bromohexyl) trimethylammonium bromide (522.1 g) and 1-bromodecane (311.7 g) were added and the mixture heated to 65° C. with stirring. After 18 hours at 65° C. the mixture was allowed to cool to room temperature. The solid was filtered off and rinsed by suspending, stirring for 30 minutes, and filtering off the solid from: methanol, 12 L; methanol, 12 L; 2 M aqueous NaCl, 22 L; 2 M aqueous NaCl, 22 L; deionized water, 22 L; deionized water, 22 L; deionized water, 22 L and isopropanol, 22 L. The solid was dried in a vacuum o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com