GaN crystal substrate, fabricating method of GaN crystal substrate, and light-emitting device

a technology of gan crystal substrate and gan crystal substrate, which is applied in the direction of crystal growth process, polycrystalline material growth, chemically reactive gas growth, etc., can solve the problems of degrading optical output and inability to form an electrode on the back surface, and achieves small light absorption coefficient and increased optical output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0051]1. Fabrication of GaN Crystal Substrate

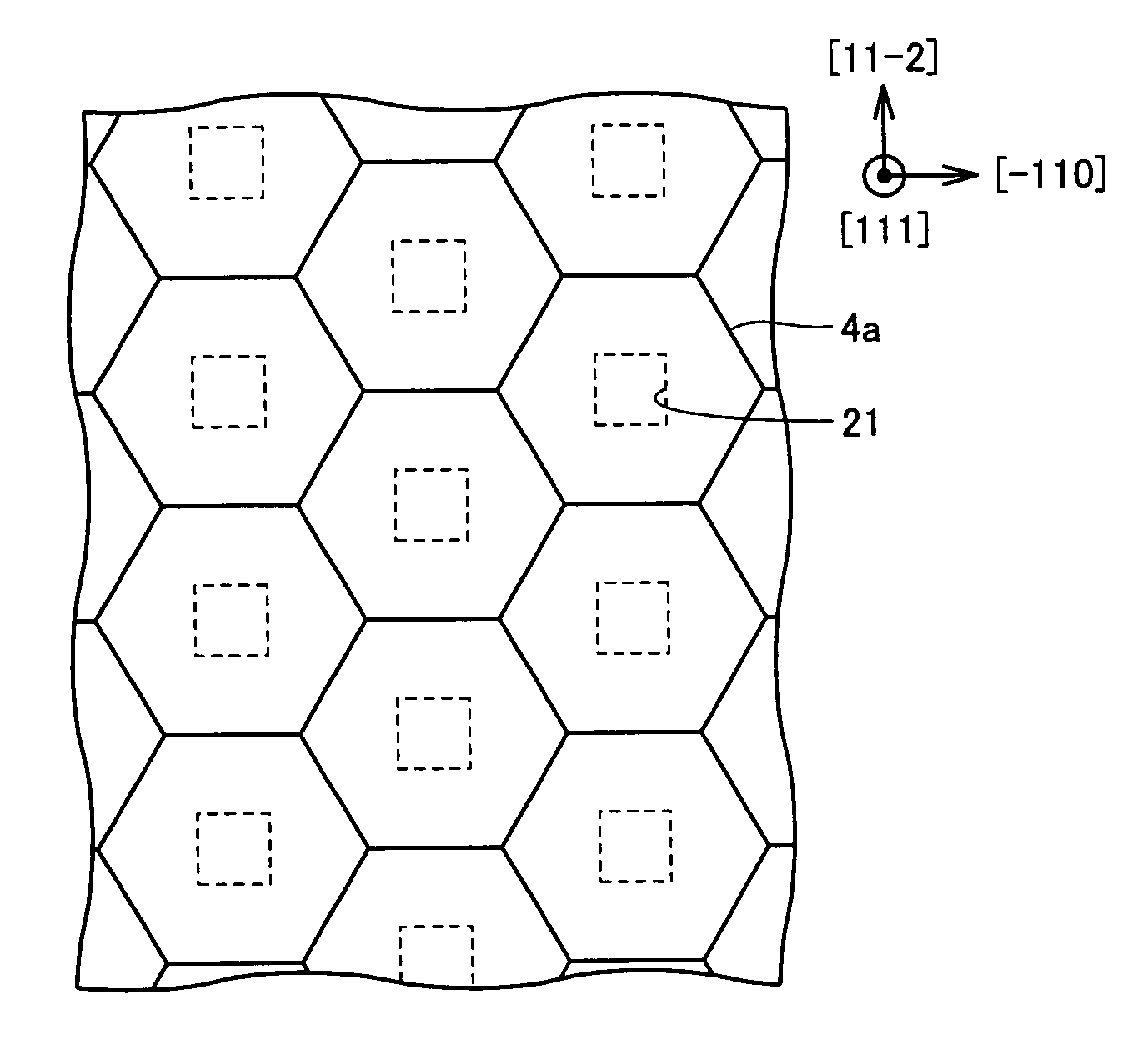

[0052]Firstly, on a GaAs substrate 1 having a diameter of 50 mm, a Si3N4 layer having a thickness of 100 nm was formed as a mask layer 2 by CVD under the atmospheric pressure, as shown in FIG. 1(a).

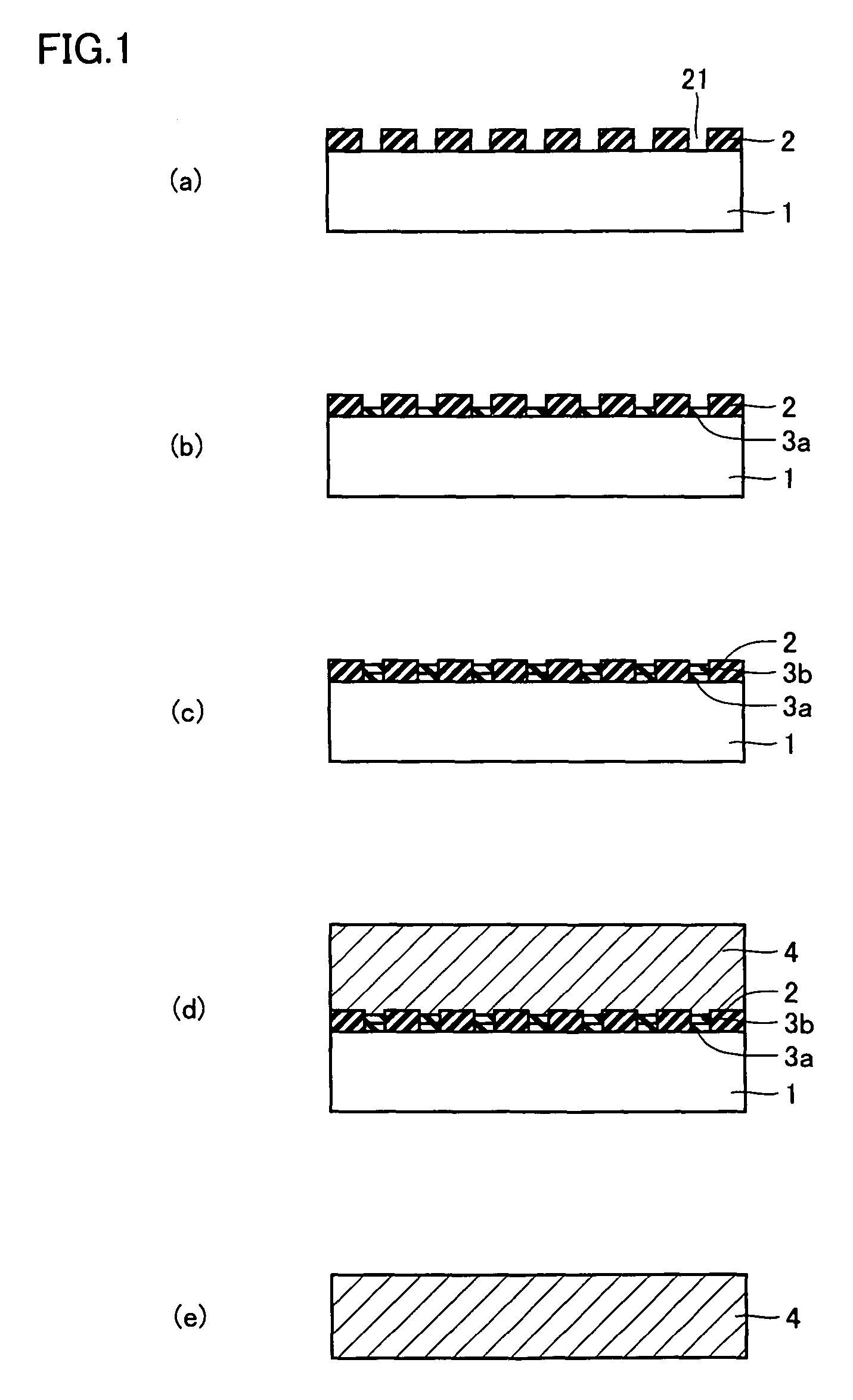

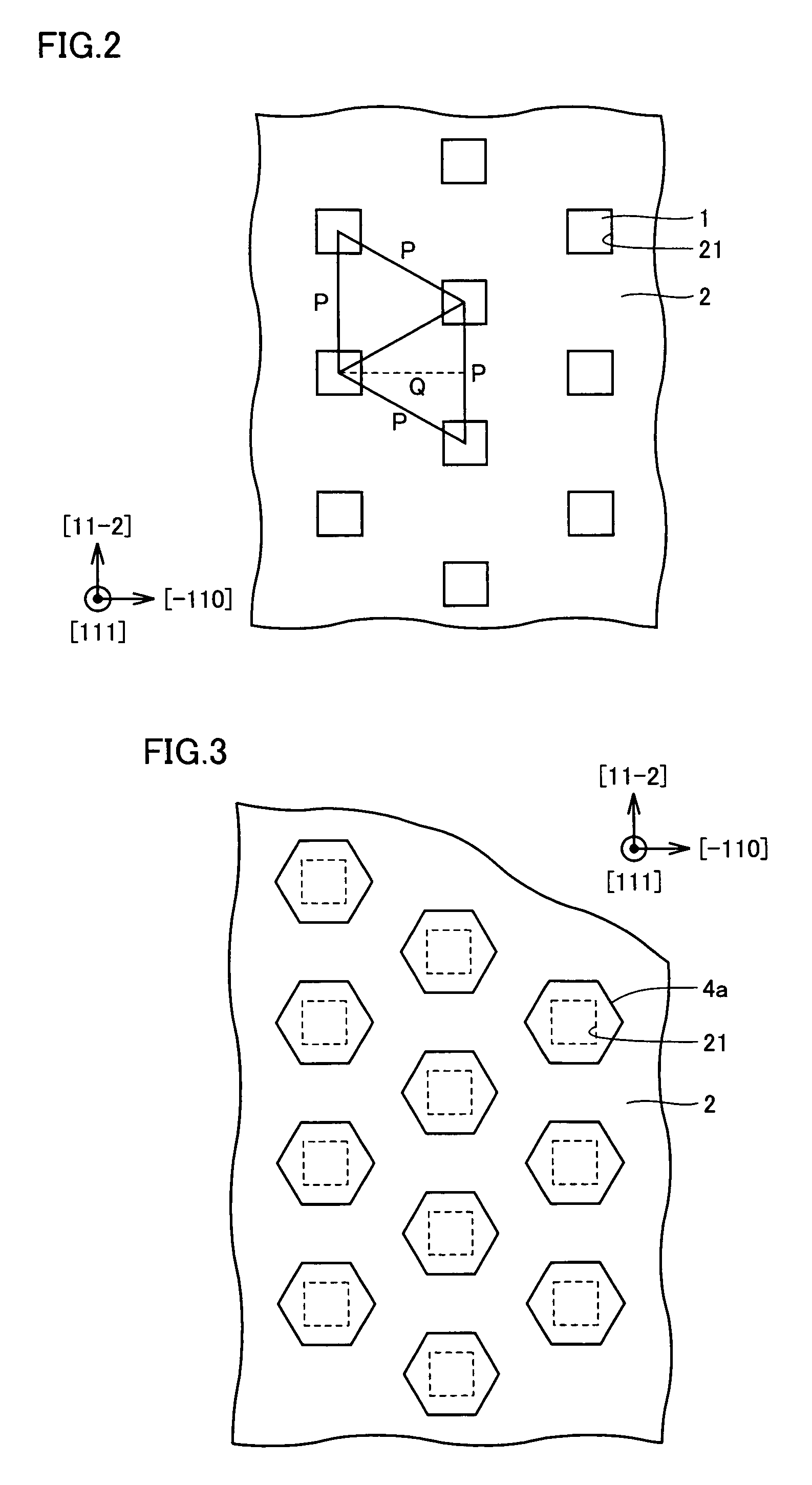

[0053]Thereafter, openings 21 were formed at mask layer 2 by photo etching to have centers corresponding to apexes of triangles with P of 4 μm and Q of 3.5 μm shown in FIG. 2. Here, opening 21 was shaped into a quadrate with a side of 1 μm.

[0054]Next, as shown in FIG. 1(b), a first GaN buffer layer 3a was grown to a thickness of 40 nm on the surface of GaAs substrate 1 exposed from openings 21 by HVPE, using HCl gas (partial pressure: 60.8 Pa) and NH3 gas (partial pressure: 1.31×104 Pa) as the source gases, at the ambient temperature of 475° C.

[0055]Subsequently, as shown in FIG. 1(c), a second GaN buffer layer 3b was grown to a thickness of 40 nm on first GaN buffer layer 3a by HVPE, using HCl gas (partial pressure: 60.8 Pa) and NH3 gas (parti...

example 2

[0070]A GaN crystal substrate of Example 2 was fabricated in a similar manner and under similar conditions as in Example 1, except that mixed gas of O2 and N2 (partial pressure: 6.55×102 Pa) containing 0.1 mass % of O2 as well as HCl gas (partial pressure: 1.25×103 Pa) and NH3 gas (partial pressure: 1.31×104 Pa) were used as the source gases. The surface of the GaN crystal substrate of Example 2 had surface roughness Ra of 3 nm.

[0071]For the GaN crystal substrate of Example 2 thus obtained, the carrier concentration and the light absorption coefficient were evaluated in a similar manner and under similar conditions as in Example 1. The results are shown in Table 1.

[0072]As shown in Table 1, the GaN crystal substrate of Example 2 had the carrier concentration of 2×1019 cm−3, and the absorption coefficient of light of 375 nm wavelength was 68 cm−1, and the absorption coefficient of light of 500 nm wavelength was 10 cm−1. Since the light absorption coefficient becomes greater as the wa...

example 3

[0075]A GaN crystal substrate of Example 3 was fabricated in a similar manner and under similar conditions as in Example 1, except that mixed gas of SiH4 and N2 (partial pressure: 93.5 Pa) containing 0.1 mass % of SiH4 as well as HCl gas (partial pressure: 1.25×103 Pa) and NH3 gas (partial pressure: 1.31×104 Pa) were used as the source gases. The surface of the GaN crystal substrate of Example 3 had surface roughness Ra of 3 nm.

[0076]For the GaN crystal substrate of Example 3 thus obtained, the carrier concentration and the light absorption coefficient were evaluated in a similar manner and under similar conditions as in Example 1. The results are shown in Table 1.

[0077]As shown in Table 1, the GaN crystal substrate of Example 3 had the carrier concentration of 5×1017 cm−3, and the absorption coefficient of light of 375 nm wavelength was 35 cm−1, and the absorption coefficient of light of 500 nm wavelength was 8 cm−1. Since the light absorption coefficient becomes greater as the wav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| light absorption coefficient | aaaaa | aaaaa |

| light absorption coefficient | aaaaa | aaaaa |

| light absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com