Pearlitic steel rail having excellent wear resistance and method of producing the same

a technology wear resistance, which is applied in the field of pearlitic steel rail, can solve the problems of reducing the affecting the service life of the rail, and affecting the service life of the rail, and achieves the effect of securing wear resistance and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0132]Table 1 tabulates the chemical components of the rail steel having the pearlite structure of this Example 1 of the present invention and the chemical components of a Comparative rail steel. Table 2 tabulates the lamella space λ (λ=ferrite thickness t1+cementite thickness t2), the ratio Rc (Rc=t2 / t1) and the result of measurement of the wear quantity after repetition of 500,000 times under a dry condition by a Nishihara type wear test of each of these steels.

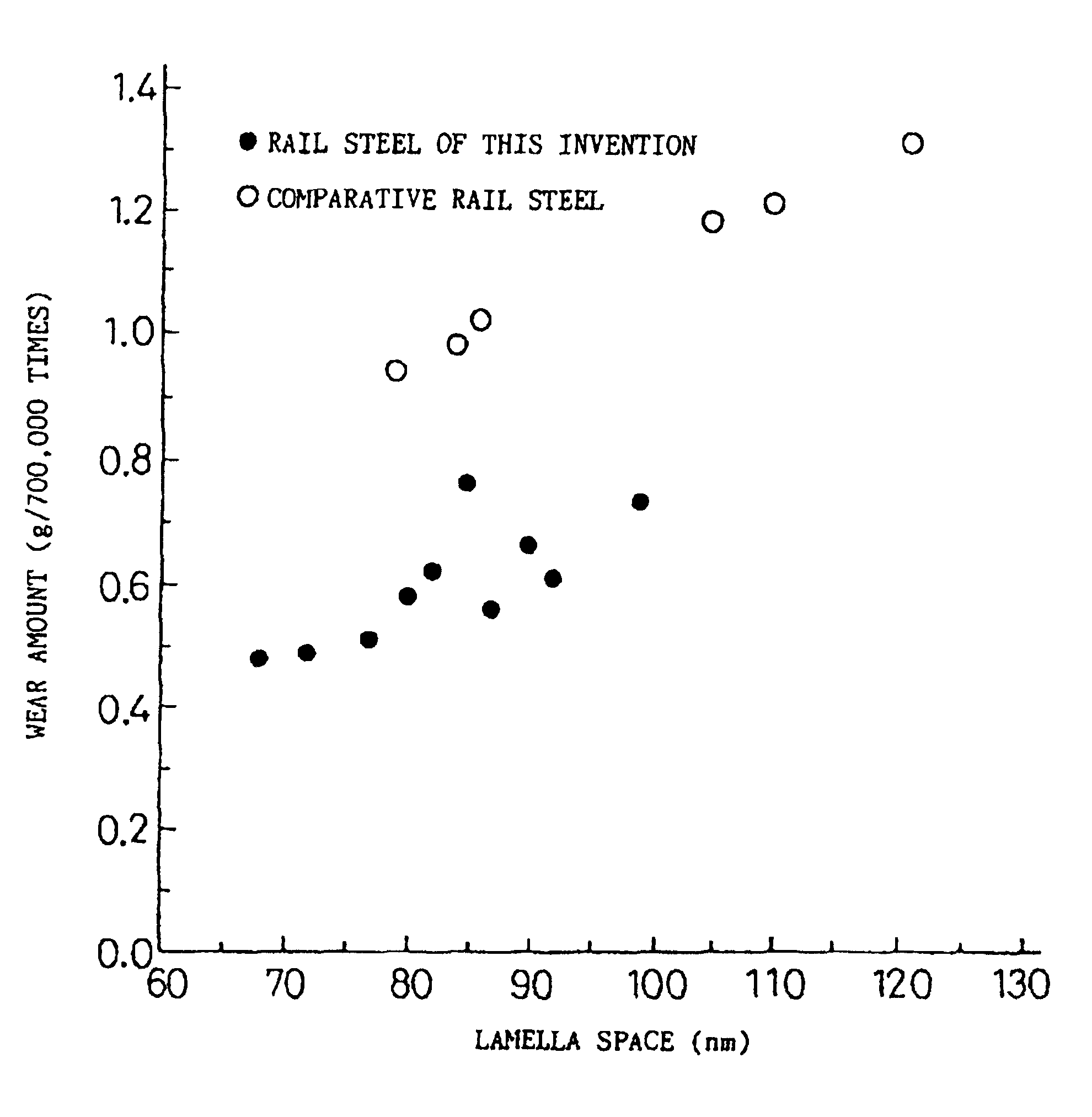

[0133]Further, FIGS. 3 and 4 show the relation between the lamella space (λ) and the ratio of the cementite thickness to the ferrite thickness and the relation between the lamella space (λ) and the wear quantity of the Comparative rail steel and the present rail steel. FIG. 5 shows a 10,000× micrograph of the present rail steel (No. 8). FIG. 5 is obtained by etching the present rail steel by a 5% nital solution and observing it through a scanning electron micrograph. A white portion in the drawing represents the cementite l...

example 2

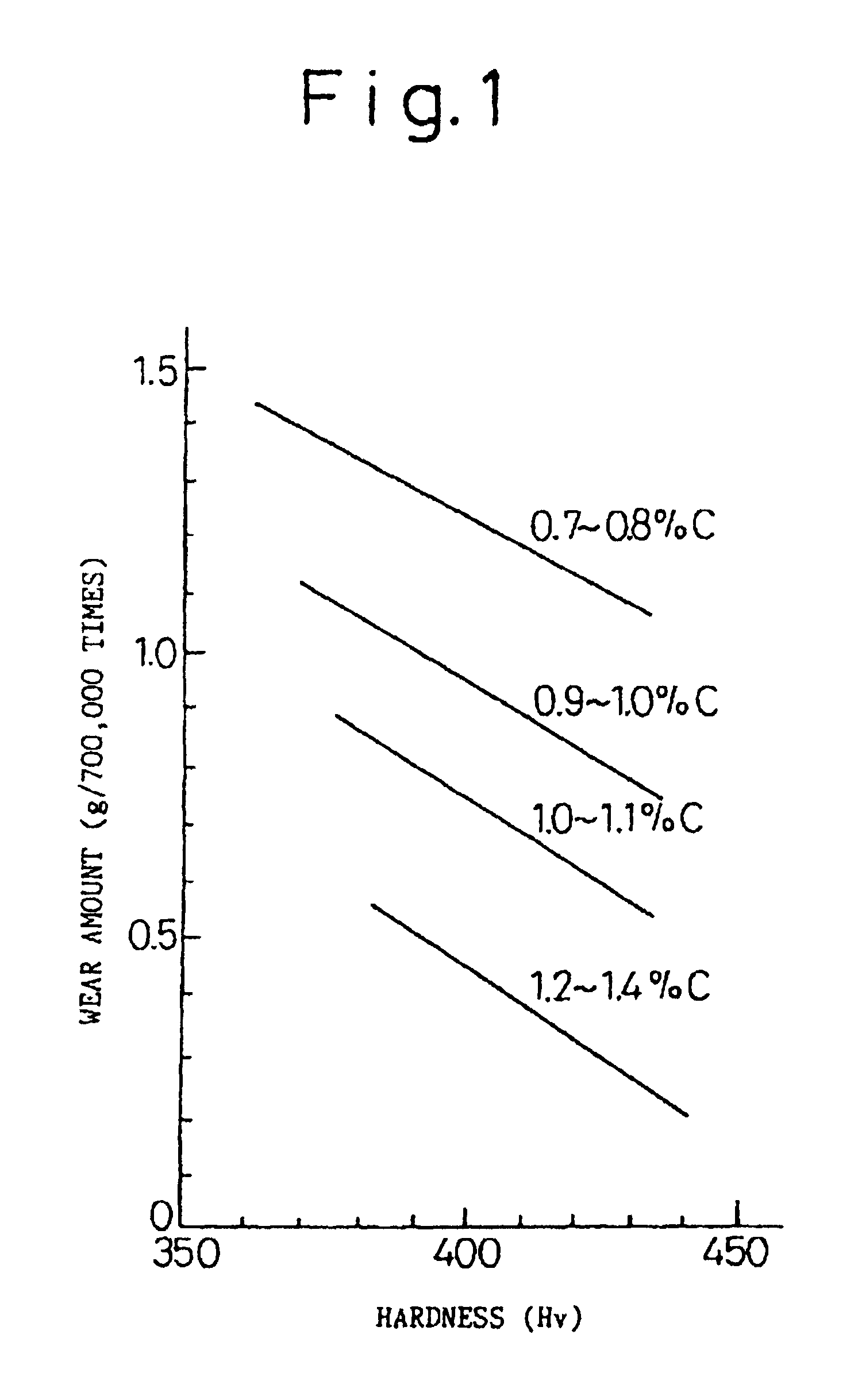

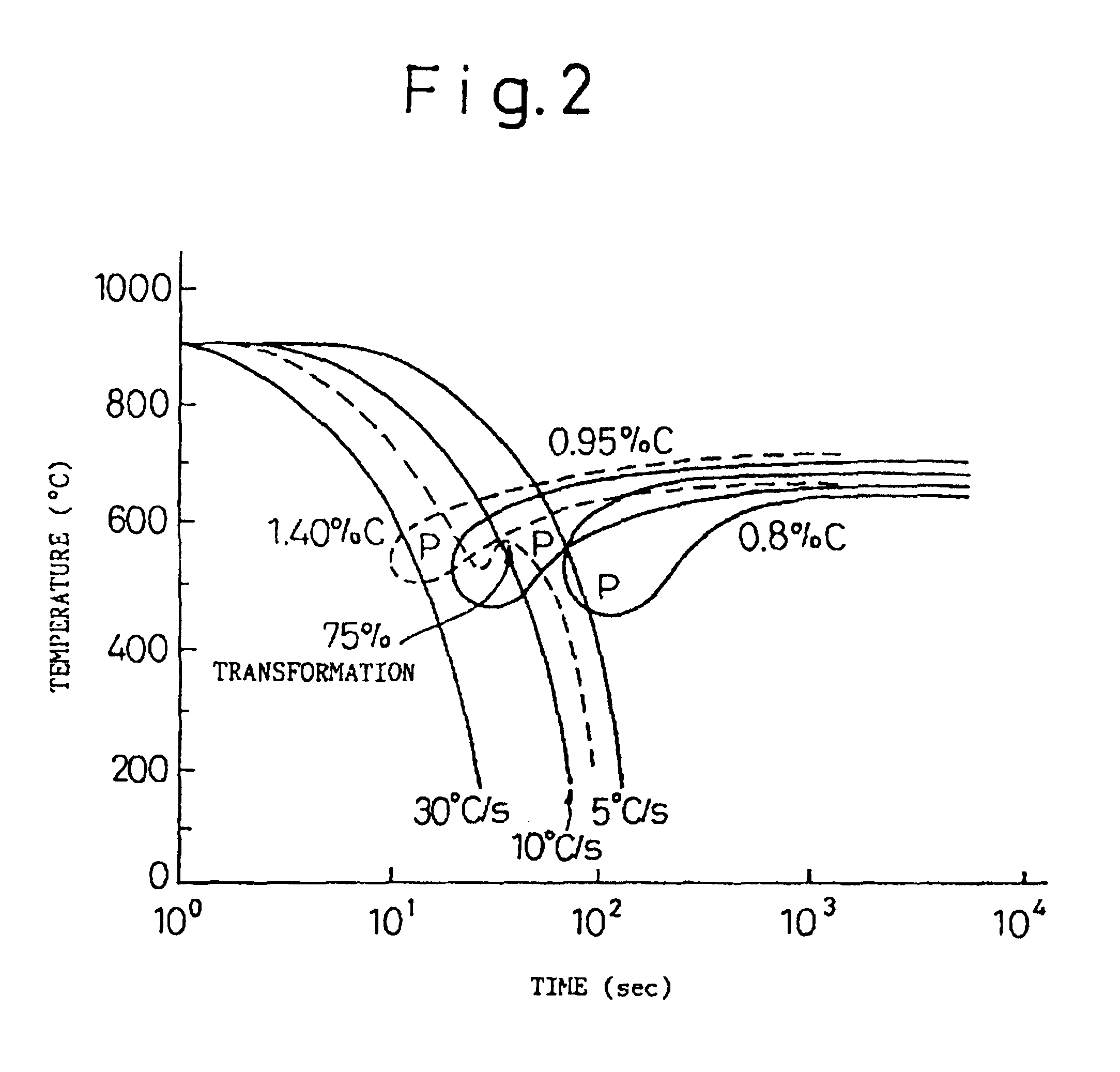

[0149]Table 3 shows the chemical components of the Present rail steels and the accelerated cooling condition, and Table 4 shows the chemical components of the Comparative rail steels and the accelerated cooling condition. Further, Tables 3 and 4 represent also the hardness after accelerated cooling and the measurement result of the wear amount after repetition of 700,000 times under the compulsive cooling condition by compressed air in the Nishihara type wear test shown in FIG. 7.

[0150]FIG. 8 graphically compares the wear test results between the Present rail steels and the Comparative rail steels shown in Tables 1 and 4 in terms of the relation between the hardness and the wear amount.

[0151]By the way, the rail construction is as follows.

Present rails (16 rails) Nos. 17 to 32

[0152]Heat-treated rails having the components within the range described above, and exhibiting the pearlite structure within the range of depth of at least 20 mm from the surfaces of the gage corner portion an...

example 3

[0156]Table 5 tabulates the chemical components, the accelerated cooling rate at the time of heat-treatment of the rails and the pearlite structure fractions at the stop of accelerated cooling of each of the present rail steels and Comparative rail steels. Further, Table 6 tabulates the hardness (Hv) of the head surface after heat-treatment of the rails and the wear amount after the Nishihara type wear test of each of the present rail steels and the Comparative rail steels. The wear test results of the rail head materials by the Nishihara type wear tester shown in FIG. 7 are shown.

[0157]By the way, the wear testing condition are as follows.[0158]Testing machine: Nishihara type wear tester[0159]Shape of testpiece: disc-like testpiece (outer diameter: 30 mm, thickness: 8 mm)[0160]Test load: 686N[0161]Slippage ratio: 20%[0162]Wheel material: pearlite steel (Hv 390)[0163]Atmosphere: in air (compulsive cooling by compressed air)[0164]Number of times of repetition: 700,000 times

[0165]

TABL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com