Planography strut attachment, mfg. method for original plate of planography printing plate and planography printing plate

A technology of lithographic printing plates and supports, applied in lithographic printing equipment, preparation of printing surfaces, printing, etc., to achieve good printing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0146] The preparation method of the solution containing rare earth element ions is not particularly limited. For example, it can be prepared by dissolving or suspending a rare earth element compound in a liquid such as water by a conventionally known method.

[0147] The rare earth element compound is not particularly limited, and examples thereof include hydroxides, rare earth element cation salt compounds, coordination compounds, and double salts.

[0148] The anion serving as the counter ion of the salt compound may be either an inorganic anion or an organic anion. Examples of inorganic anions include halide ions (halogen elements can be fluorine atoms, chlorine atoms, bromine atoms, and iodine atoms), carbonate ions, borate ions, potassium ions, nitrate ions, sulfite ions, and sulfate ions. , perchlorate ion, perbromate ion, periodate ion, phosphonate ion, phosphate ion, cyanate ion, thiocyanate ion, PF 6 - , BF 4 - Wait.

[0149] Examples of organic anions include i...

Embodiment 1-1

[0394]

[0395] Use contains Si: 0.06% (mass), Fe: 0.30% (mass), Cu: 0.005% (mass), Mn: 0.001% (mass), Mg: 0.001% (mass), Zn: 0.001% (mass), Ti: 0.03% (mass), aluminum alloy with the balance being Al and unavoidable impurities, which is made into molten metal, processed and filtered, and made into an ingot with a thickness of 500 mm and a width of 1200 mm by DC casting. The surface layer with an average thickness of 10 mm was cut off with a surface cutting machine, and then soaked at 550 ° C for about 5 hours, then cooled to 400 ° C, and a rolled plate with a thickness of 2.7 mm was produced using a hot rolling machine. Heat treatment was carried out at 500° C. in a continuous annealing furnace, and then cold rolled to a thickness of 0.24 mm to obtain a JIS 1050 aluminum plate. This aluminum plate was made into a width of 1030 mm and subjected to the surface treatment described below to obtain a lithographic printing plate support.

[0396]

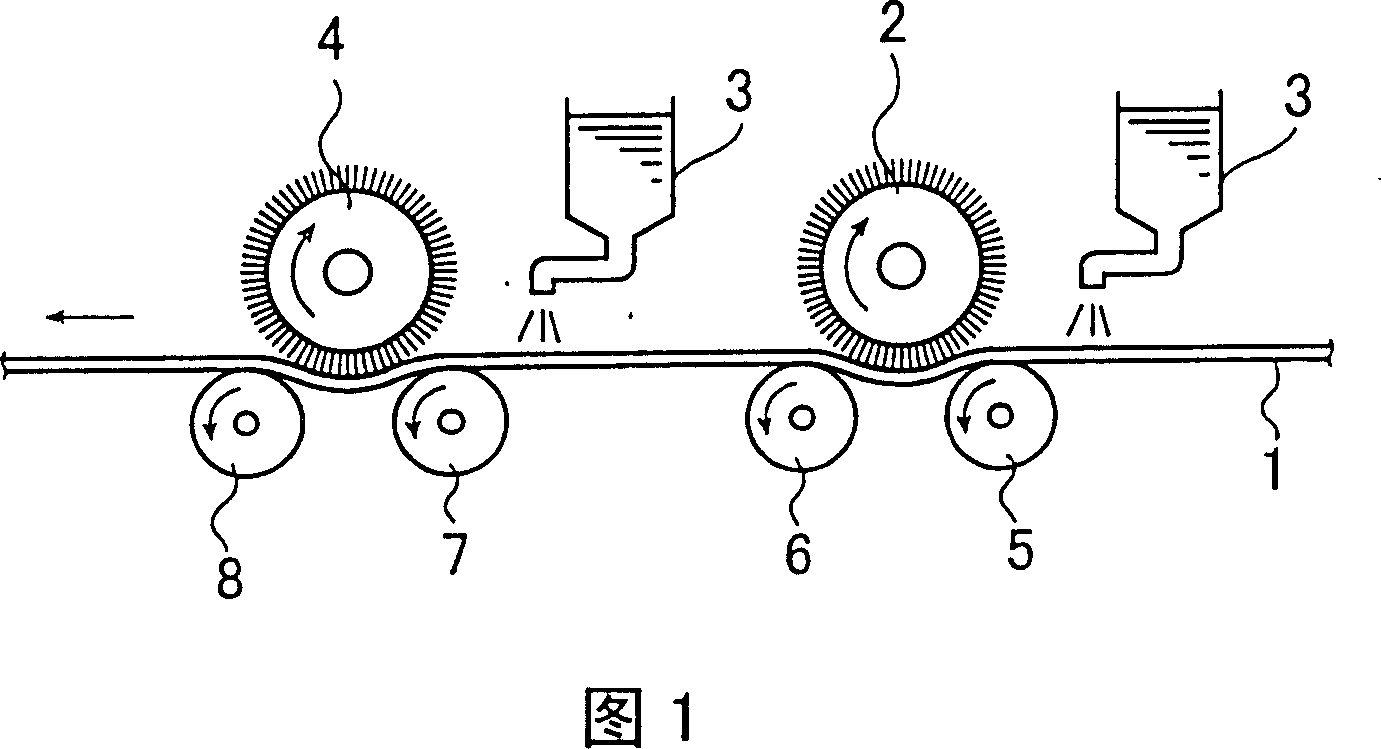

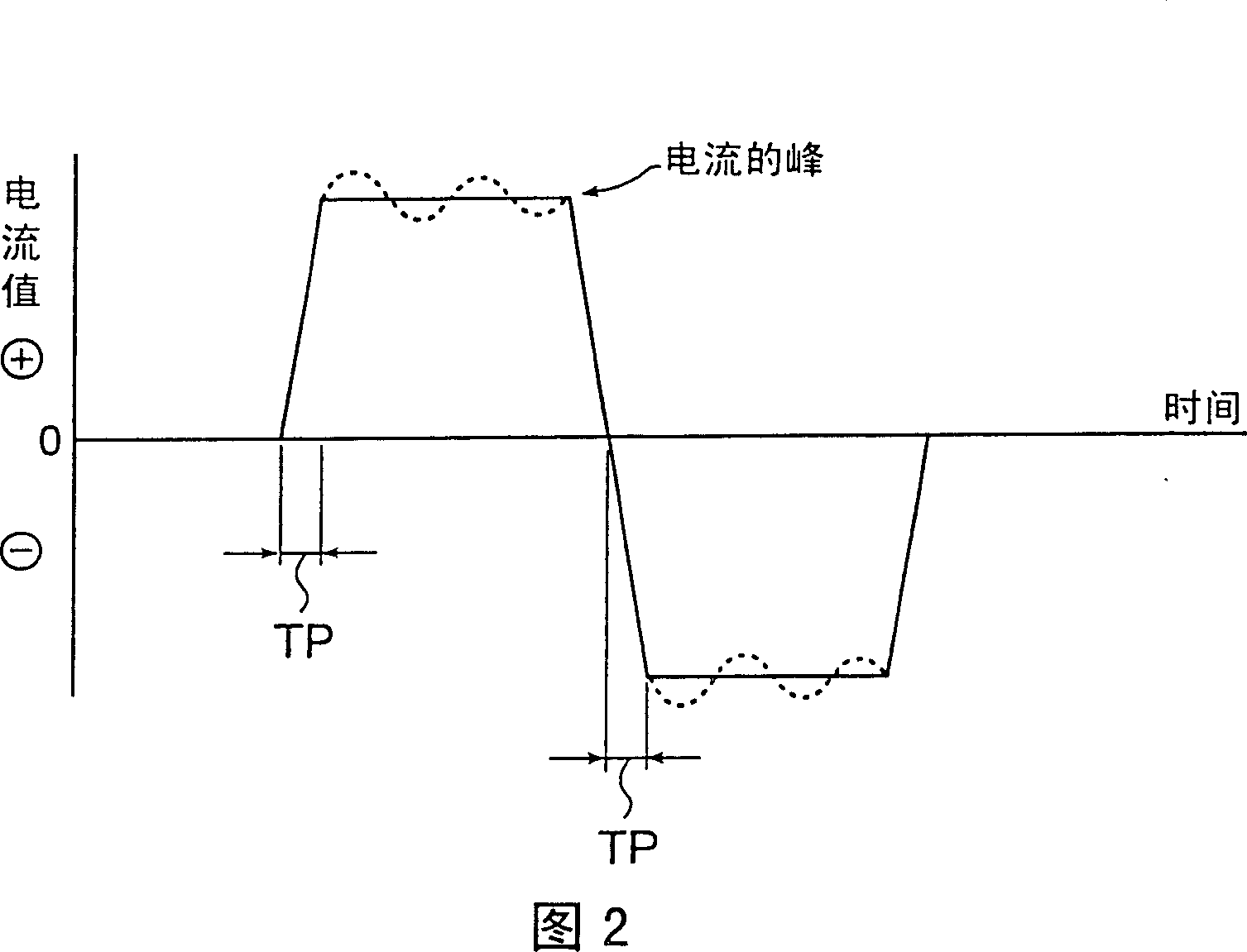

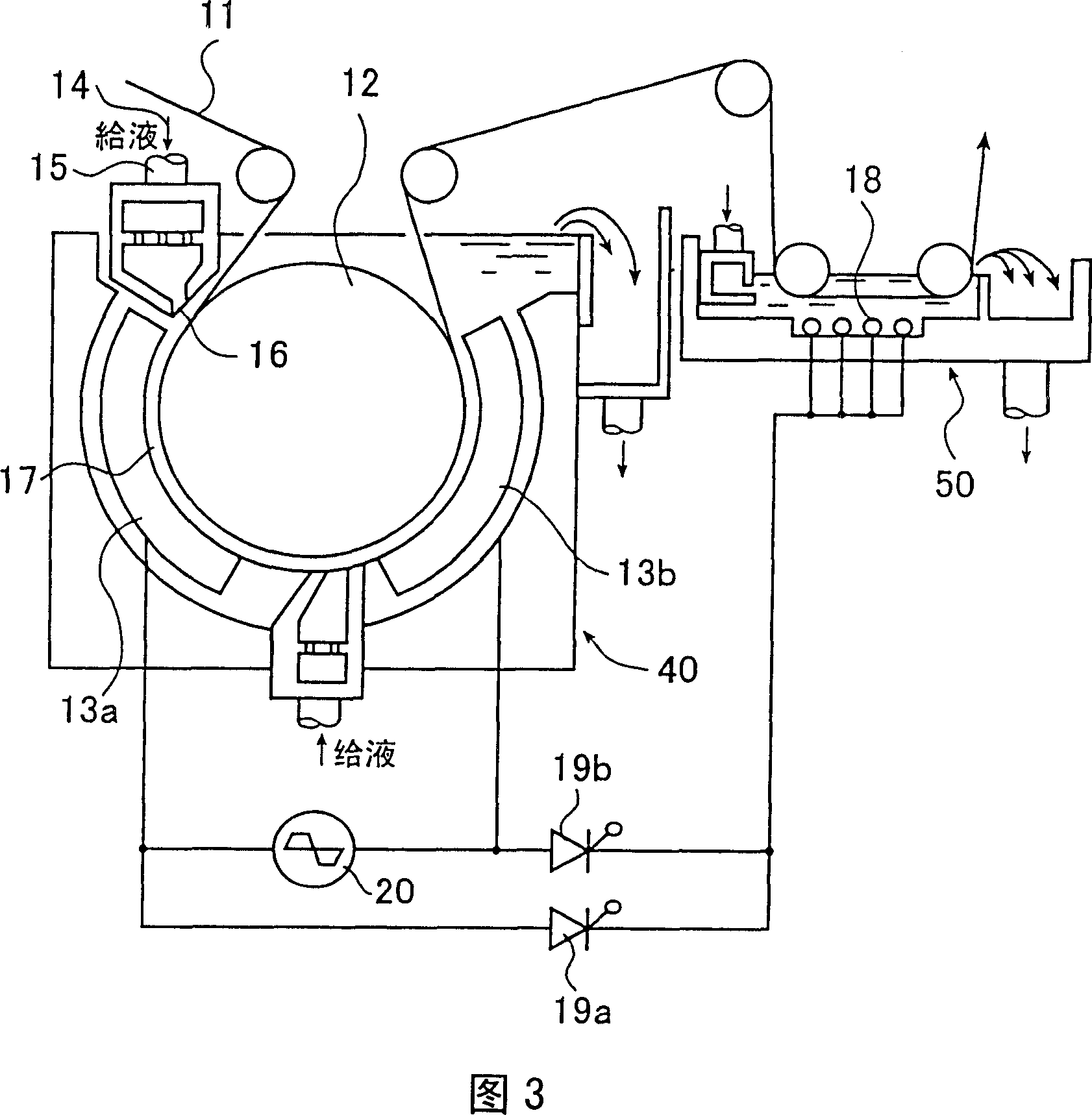

[0397] The surface treatment ...

Embodiment 1-2~1-19

[0439] Change the aqueous solution concentration, liquid temperature and immersion time in the above-mentioned (h), and the rare earth element compound type, aqueous solution concentration, liquid temperature and immersion time in the above-mentioned (i-1) to be shown in Table 2, and in addition follow the same as The original lithographic printing plates were prepared by the same method as in Example 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion amount | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com