Method for preparing photocatalyst of platinum-carried cadmium sulfide

A photocatalyst, cadmium sulfide technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. The effects of improved photocorrosion ability, improved hydrogen production activity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Spread 2g of cadmium acetate evenly in the magnetic boat, place it in the center of the quartz tube furnace, raise the temperature of the quartz tube furnace to 400°C at a heating rate of 10°C / min, and thermally decompose cadmium acetate at this temperature for 1 hour , and then lowered to room temperature to obtain a cadmium oxide precursor.

[0031] 2) Select dry hydrogen sulfide to pass into the quartz tube furnace at a flow rate of 5ml / min, raise the temperature of the quartz tube furnace to 400°C at a rate of 10°C / min, and heat the cadmium oxide precursor at 400°C Vulcanization 4h.

[0032] 3) Turn off the quartz tube furnace. Under the hydrogen sulfide atmosphere, the quartz tube furnace cools down naturally. At 50°C, turn off the hydrogen sulfide gas, and continue cooling to room temperature to obtain cadmium sulfide.

[0033] 4) Loading the prepared cadmium sulfide on the noble metal platinum by photoreduction method to obtain the platinum-loaded cadmium sul...

Embodiment 2

[0036] The difference between this embodiment and Example 1 is that the quartz tube furnace in step 1) is raised to 300°C, and the quartz tube furnace in step 2) is raised to 400°C. The rest are the same as in Example 1, and can also be obtained Platinum-supported cadmium sulfide photocatalyst.

Embodiment 3

[0038] This embodiment is different from Example 1 in that the quartz tube furnace in step 1) is raised to 400°C, and the quartz tube furnace in step 2) is raised to 300°C, and the rest are the same as in Example 1, and can also be obtained Platinum-supported cadmium sulfide photocatalyst.

[0039]The difference between this embodiment and Example 1 is that the quartz tube furnace in step 1) is raised to 500°C, and the quartz tube furnace in step 2) is raised to 400°C. The rest are the same as in Example 1, and can also be obtained Platinum-supported cadmium sulfide photocatalyst.

[0040] The above experimental examples can also be cited, as long as it is within the scope of the present invention, suitable cadmium sulfide can be obtained, but in order to further simplify the process, the parameters of experimental example 1 are the optimal choice.

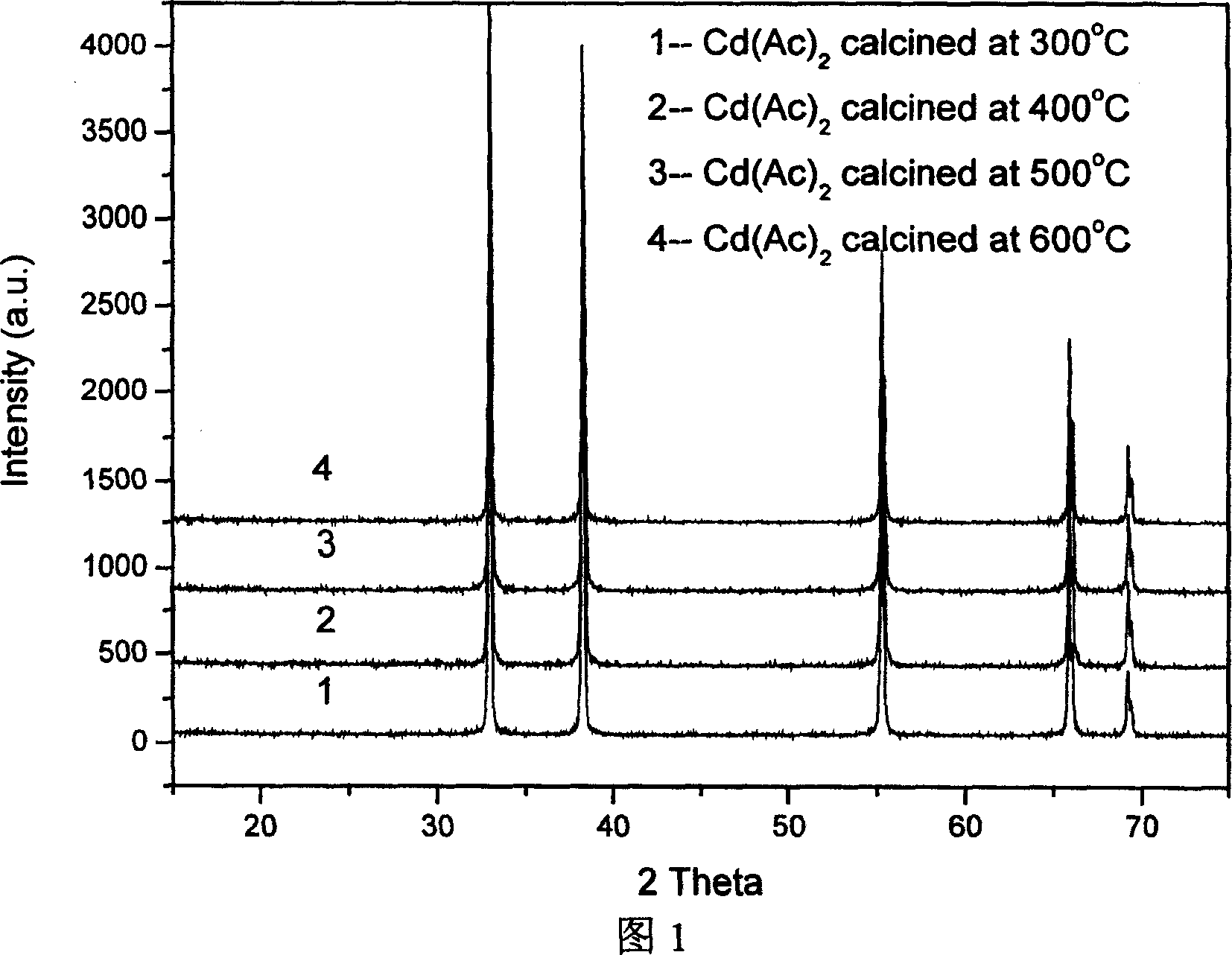

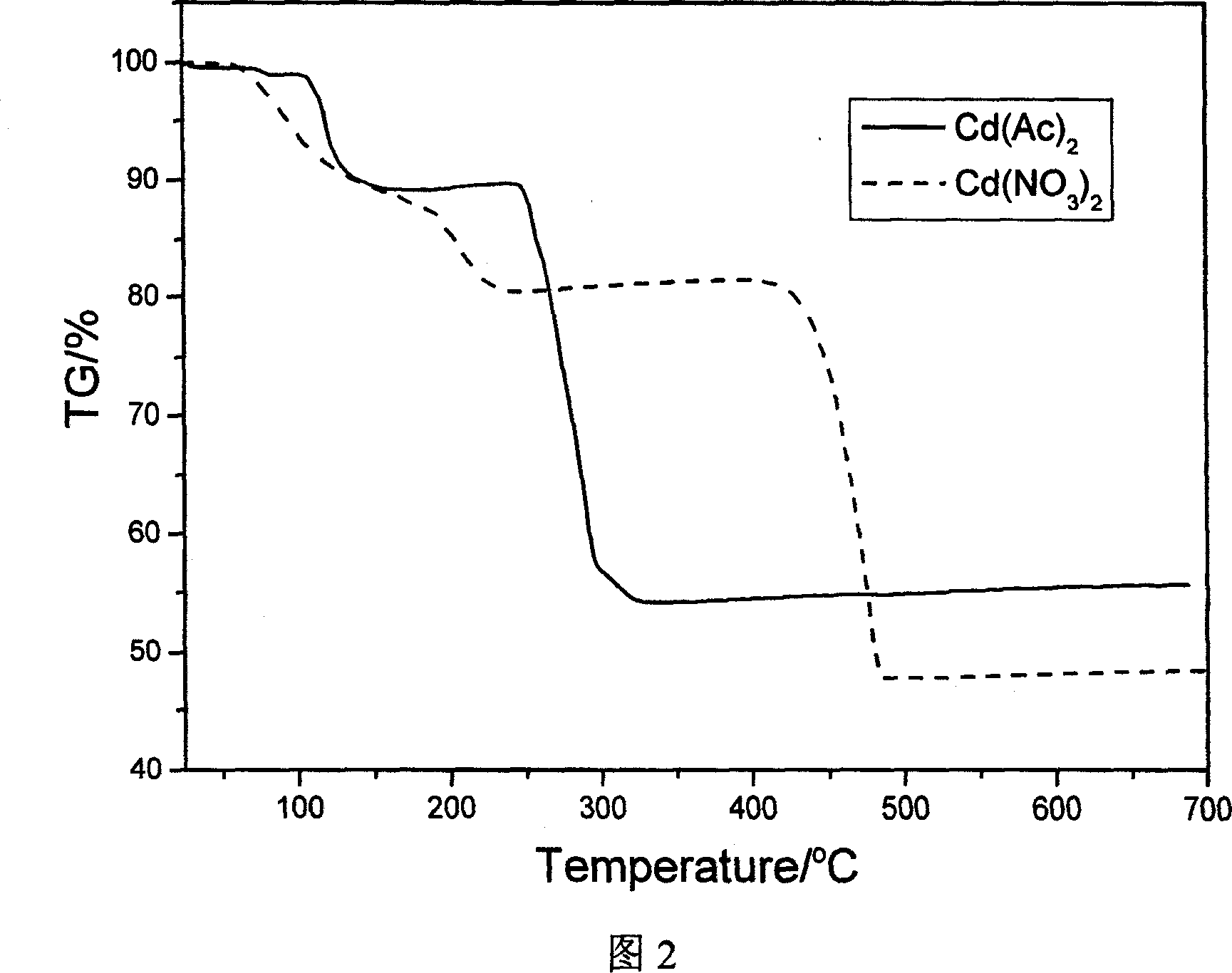

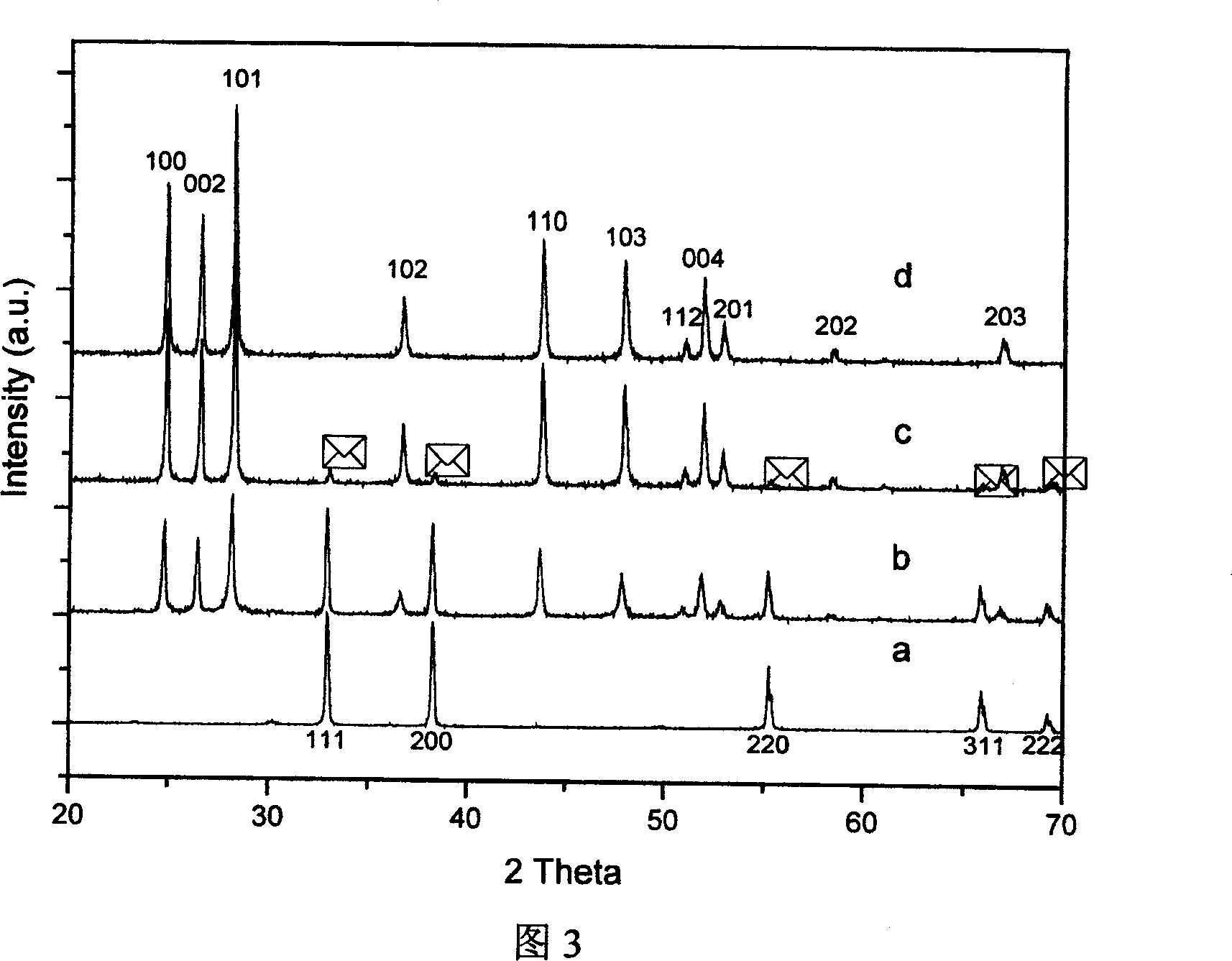

[0041] Referring to Fig. 1, Fig. 1 has provided the X-ray diffraction pattern (XRD) of the decomposition product of cadmium ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com