Low-modulus high-elongation high-adhesive-strength organosilicon sealing material and its preparing method

A high elongation, sealing material technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low bonding strength of substrates, low modulus, high elongation, and reduced adhesion. Long curing time, high elongation, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

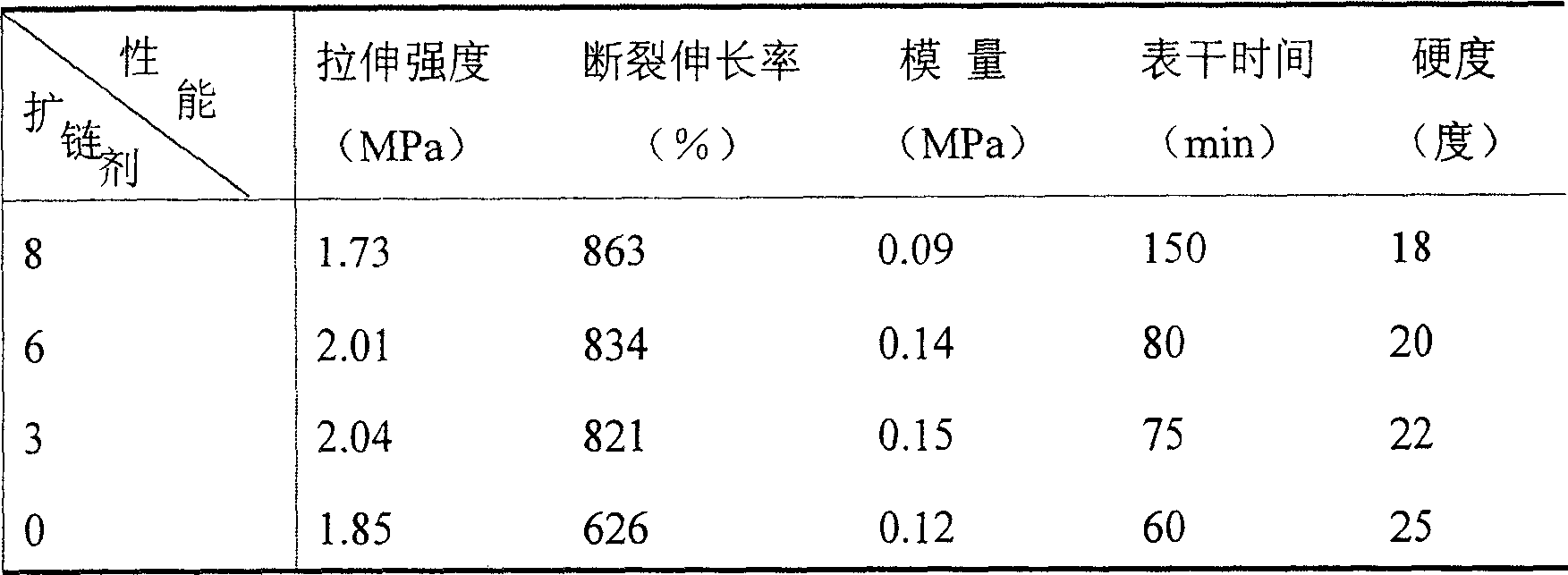

[0035] 100 parts of hydroxyl-terminated polydimethylsiloxane (25° C., 53000 cP), 100 parts of dried superfine activated calcium carbonate with a particle size range of 0.04-20 μm treated with stearic acid were placed in a vacuum-tight condition Mix in a planetary mixer for 2-3 hours to obtain the base rubber; then add 8 parts of dimethyl dibutylketoxime silane chain extender and 5 parts of methyl tributyl ketoxime silane crosslinking agent, under vacuum airtight condition Mix for 8-10 minutes; finally add 0.1 part of dibutyltin dilaurate catalyst and 1 part of 7A silane coupling agent, mix for 8-10 minutes, vacuum remove air bubbles and some low molecular substances generated during the reaction, and then seal and store .

[0036] The other three groups of silicone sealing materials were prepared in the same way, except that 6 parts, 3 parts and 0 parts of dimethyldibutylketoximosilane chain extender were added respectively. Inject the prepared silicone sealing material into ...

Embodiment 2

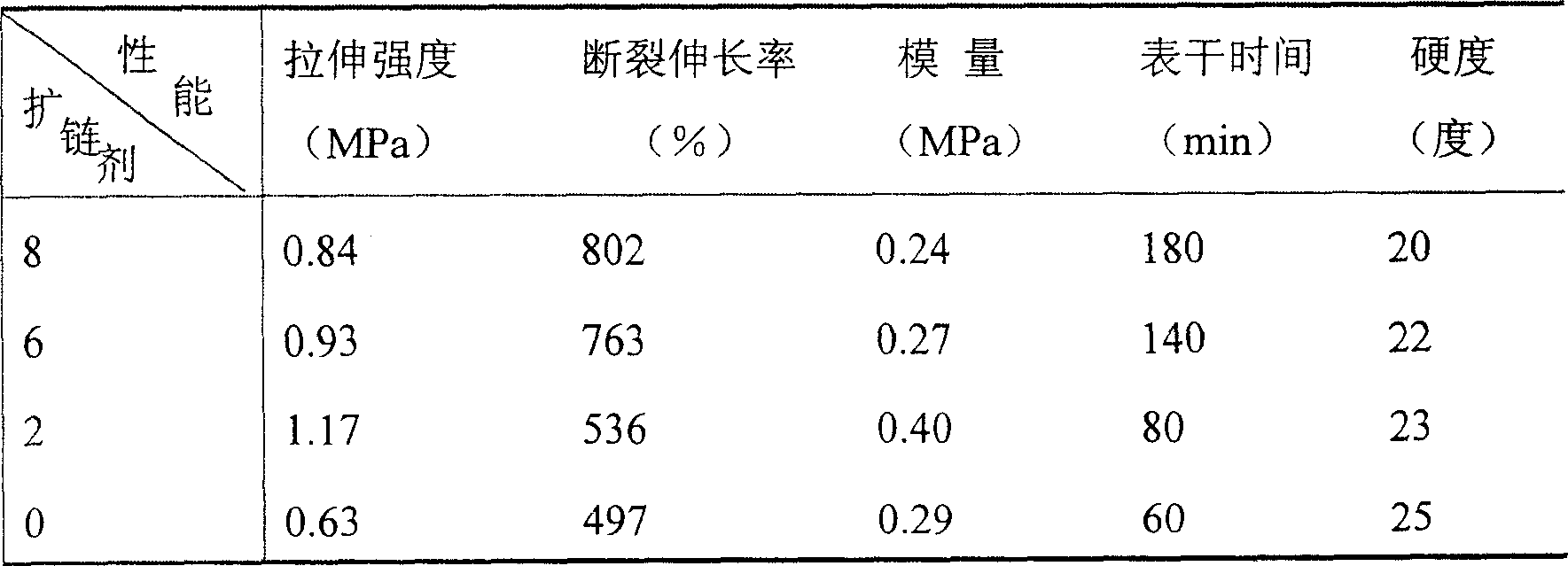

[0041] 100 parts of hydroxyl-terminated polydimethylsiloxane (25° C., 53000 cP), 100 parts of dried superfine activated calcium carbonate with a particle size range of 0.04-20 μm treated with stearic acid were placed in a vacuum-tight condition Mix in a planetary mixer for 2-3 hours to obtain the base rubber; then add 8 parts of methyl vinyl dibutylketoxime silane chain extender and 4 parts of methyl tributylketoxime silane cross-linking agent, vacuum airtight condition Mix at low temperature for 8-10 minutes; finally add 0.1 part of dibutyltin dilaurate catalyst and 1 part of 7A silane coupling agent, mix for 8-10 minutes, remove air bubbles and some low molecular substances generated in the reaction by vacuum, seal save.

[0042] The other three groups of silicone sealing materials were prepared in the same way, except that 6 parts, 2 parts and 0 parts of methylvinyl dibutylketoxime silane chain extender were added respectively. Inject the prepared silicone sealing material...

Embodiment 3

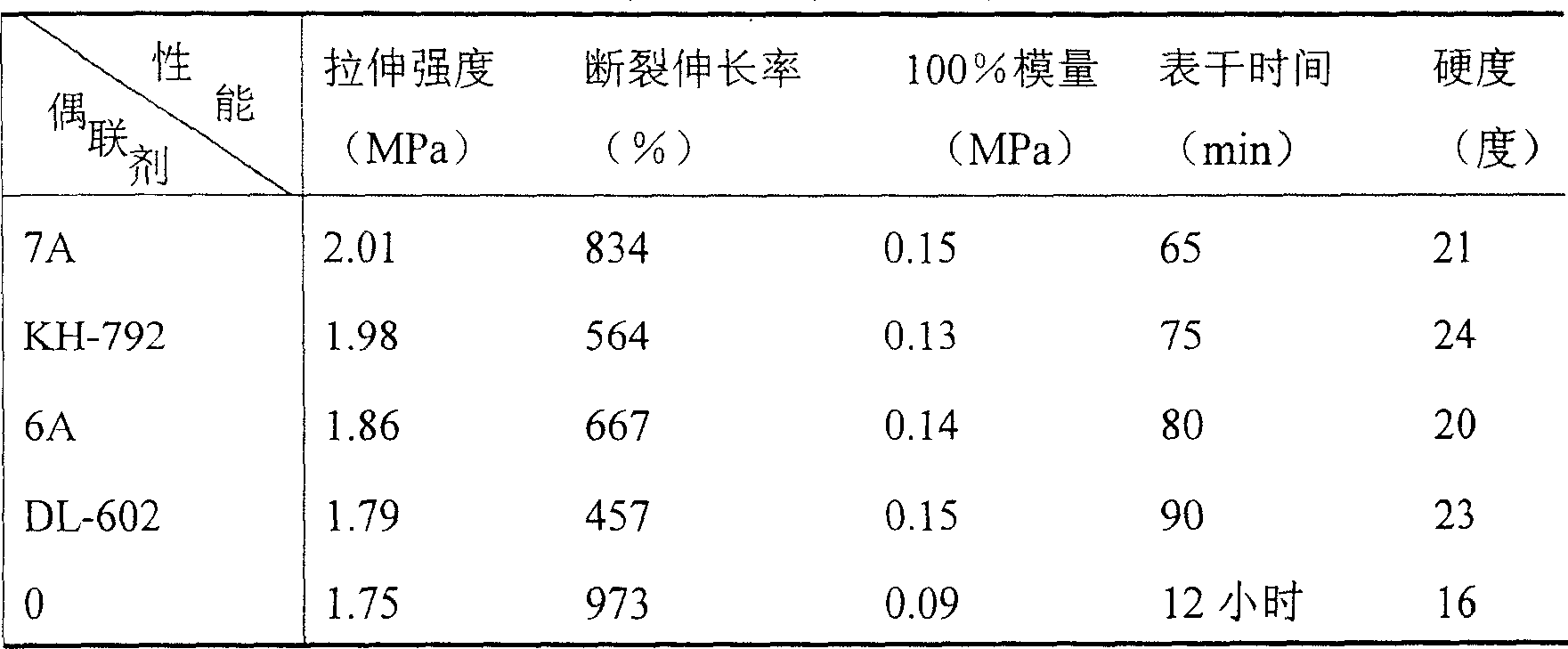

[0047] 100 parts of hydroxyl-terminated polydimethylsiloxane (25° C., 53000 cP), 100 parts of dried superfine activated calcium carbonate with a particle size range of 0.04-20 μm treated with stearic acid were placed in a vacuum-tight condition Mix in a planetary mixer for 2-3 hours to obtain the base compound. Then add 6 parts of dimethyl dibutylketoxime silane chain extender and 5 parts of methyl tributyl ketoxime silane crosslinking agent, and mix for 8-10 minutes under vacuum airtight condition; finally add 0.1 part of dibutyl dilaurel Acid tin catalyst and 1 part of 7A silane coupling agent, mix for 8-10 minutes, vacuum remove air bubbles and some low molecular substances generated in the reaction, and then seal and store.

[0048] The other four groups of silicone sealing materials were prepared in the same way, except for the type of silane coupling agent. One part of KH-792, 6A, DL-602 or no silane coupling agent is added respectively. Inject the prepared silicone se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com