Method for recovering nickel and cobalt from nickel oxide ore and nickel silicide ore

A technology of nickel oxide ore and nickel silicate, which is applied in the field of mineral processing engineering, can solve the problems of high metal recovery rate and failure to achieve it, and achieve good economic benefits, no tail gas emissions, and simple and easy processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

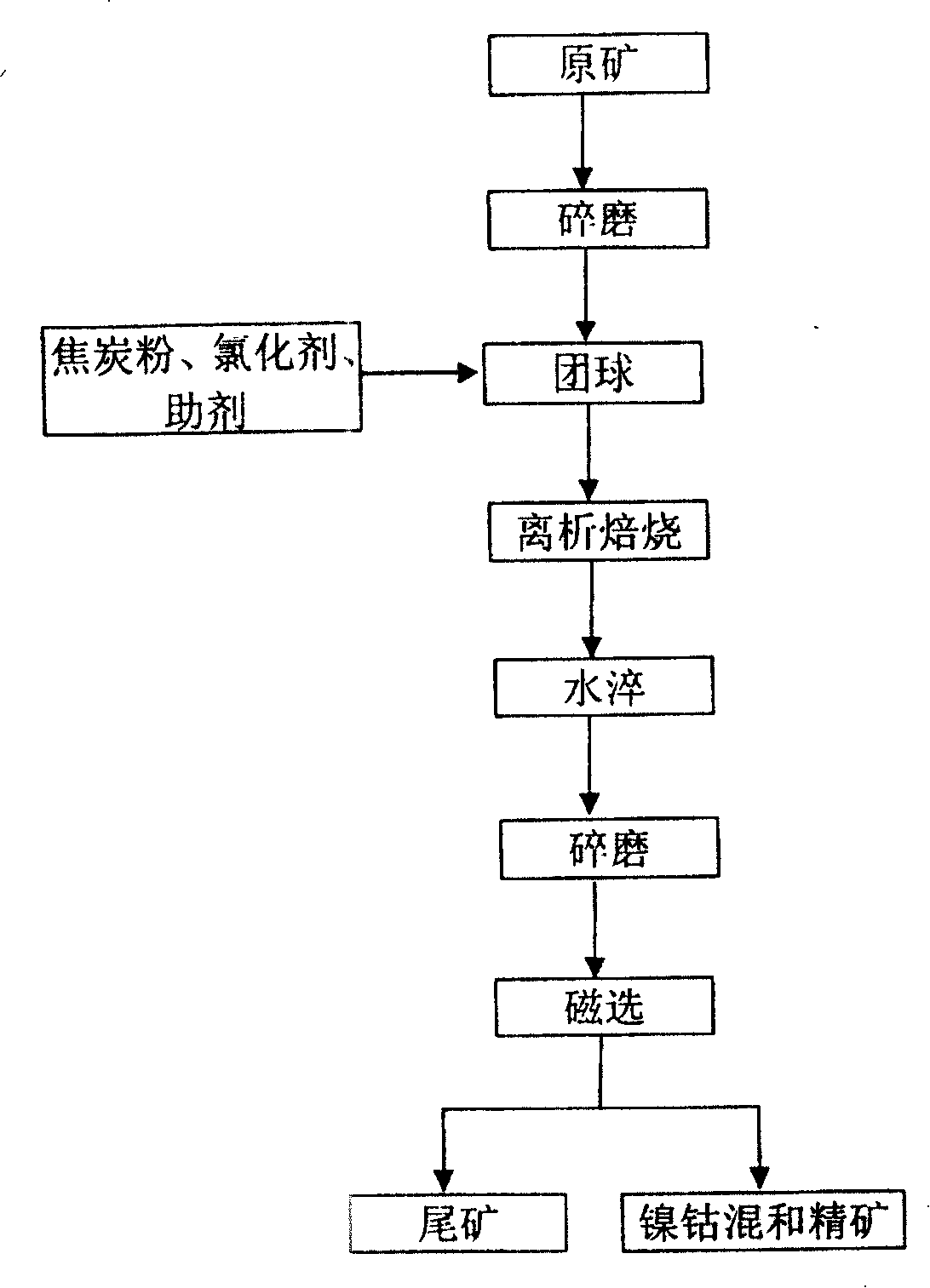

Image

Examples

Embodiment 1

[0021] Example 1: Yuanjiang nickel silicate ore, the raw ore contains 1.2% nickel and 0.08-0.1% cobalt. Crush the raw ore to -3mm-0mm, and then grind it to -200 mesh with a Raymond mill, accounting for 80-90wt%, add 12.5wt% coke powder with a particle size of -3mm-0mm, chlorinating agent CaCl 2 25wt%, additive MOP 0.5wt%, mixed pellets, made into pellets with a particle size of 8-15mm, and dried in the air until the moisture content was less than 8%. Segregation and roasting in a segregation rotary kiln at 400-500 ° C, the rotary kiln speed is 1.2 rpm, the roasting time is 1-1.2 hours, the roasting fuel is pulverized coal, the roasting method is counter-current roasting, the roasted products are unloaded into the pool and quenched with water. The quenched product is taken out and crushed and then ground. The grinding fineness is -200 mesh, accounting for 75~78wt%. The nickel grade of the mixed concentrate is 11.5%, the recovery rate is 84.5%, the cobalt grade is 0.56%, and t...

Embodiment 2

[0022] Example 2: Laterite nickel ore in the Philippines. The ore sample is taken from the Philippines. The grade of nickel in the raw ore is 1.28%, and the grade of cobalt is 0.041%. Crushing the raw ore to -3mm-0mm, and then grinding it to -200 mesh with a Raymond mill, accounting for 80-90wt%, adding 10wt% coke powder with a particle size of -3mm-0mm, 30wt% chlorinating agent (NaCl), and additives ( Copper dimethyl thiocarbamate) 0.6wt% mixed pellets, particle size 5-10mm, air-dried in the air until the moisture content is <3-5%, added to the high-temperature zone with a temperature of 1000-1200°C and a kiln tail temperature of 400 Segregation roasting in a segregation rotary kiln at ~500°C, the rotary kiln speed is 1 rpm, the roasting time is 1.5-2 hours, the roasting fuel is pulverized coal, the roasting method is countercurrent roasting, and the roasted products are discharged into the water pool for water quenching, water quenching The product is taken out and crushed a...

Embodiment 3

[0023] Example 3: Hanyuan cobalt-nickel ore, the raw ore contains 0.14% nickel grade and 0.25% cobalt grade. Crush the raw ore to -3mm-0mm, and then grind it to -200 mesh with Raymond Mill to account for 80-90wt%, add 5wt% of coke powder with a particle size of -3mm-0mm, chlorinating agent (CaCl 2 ) 23wt%, additives (CuCl: NH 4Cl=1:1) 1wt% mixed pellets, particle size 8-15mm, air-dried to moisture <3-5%, add high temperature zone temperature 1000-1300°C kiln tail temperature 500-600°C Isolation roasting in the segregation rotary kiln, the rotating speed of the rotary kiln is 2 rpm, and the roasting time is 1-1.5 hours. Grinding after crushing, the grinding fineness is -200 mesh, accounting for 95wt%, sorting with a magnetic separator with a magnetic field strength of H = 1800±50 gauss, the magnetic product is nickel-cobalt mixed concentrate I, the nickel grade of the concentrate is 2.12% , the recovery rate is 66.62%, the cobalt grade is 3.5%, and the recovery rate is 66.03%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com