Method for preparing semiconductor nano-material and processing organic-inorganic wastewater synchronously

A technology of organic wastewater and simultaneous treatment, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of secondary pollution, incomplete and complete pollution, loss, etc., to reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

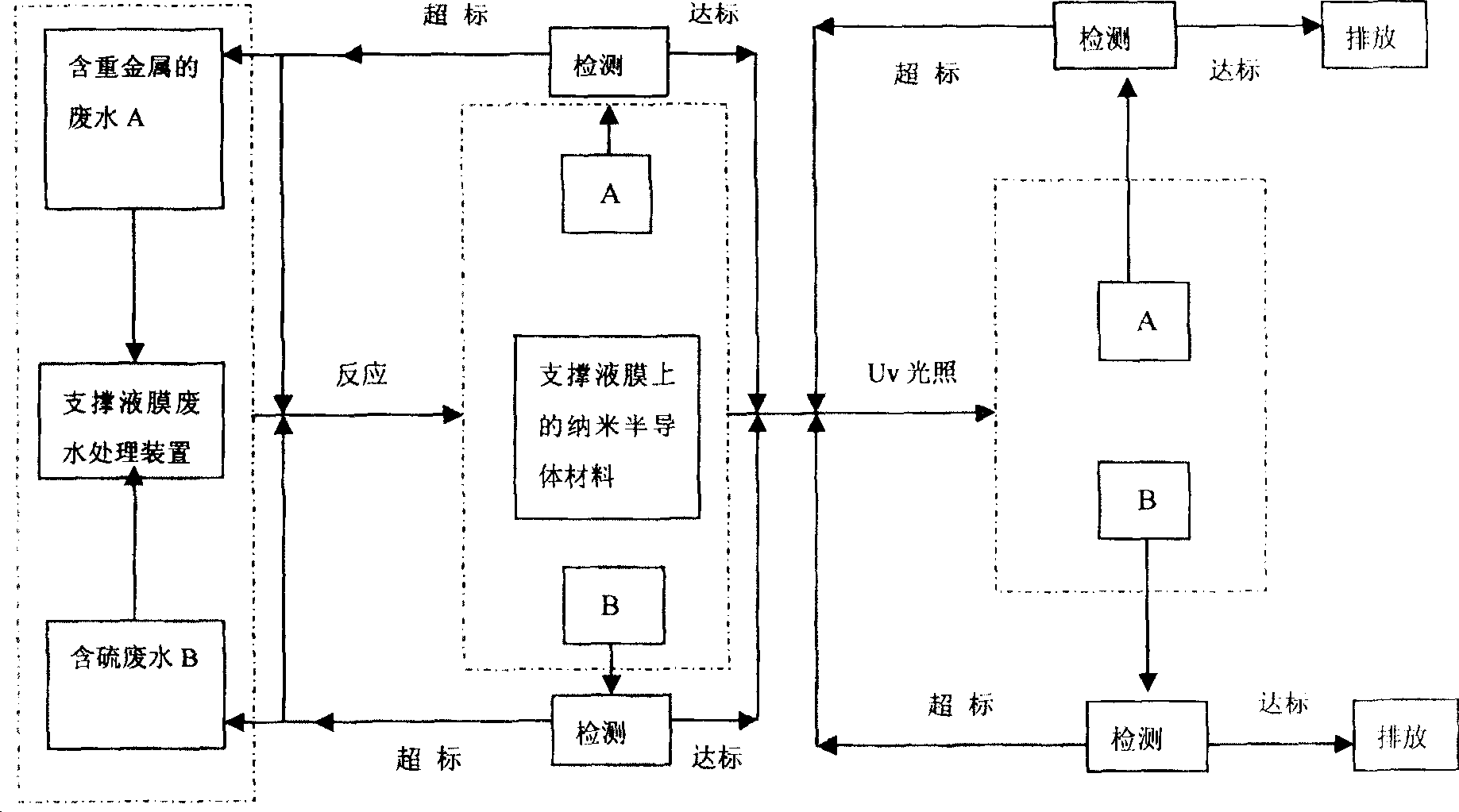

Method used

Image

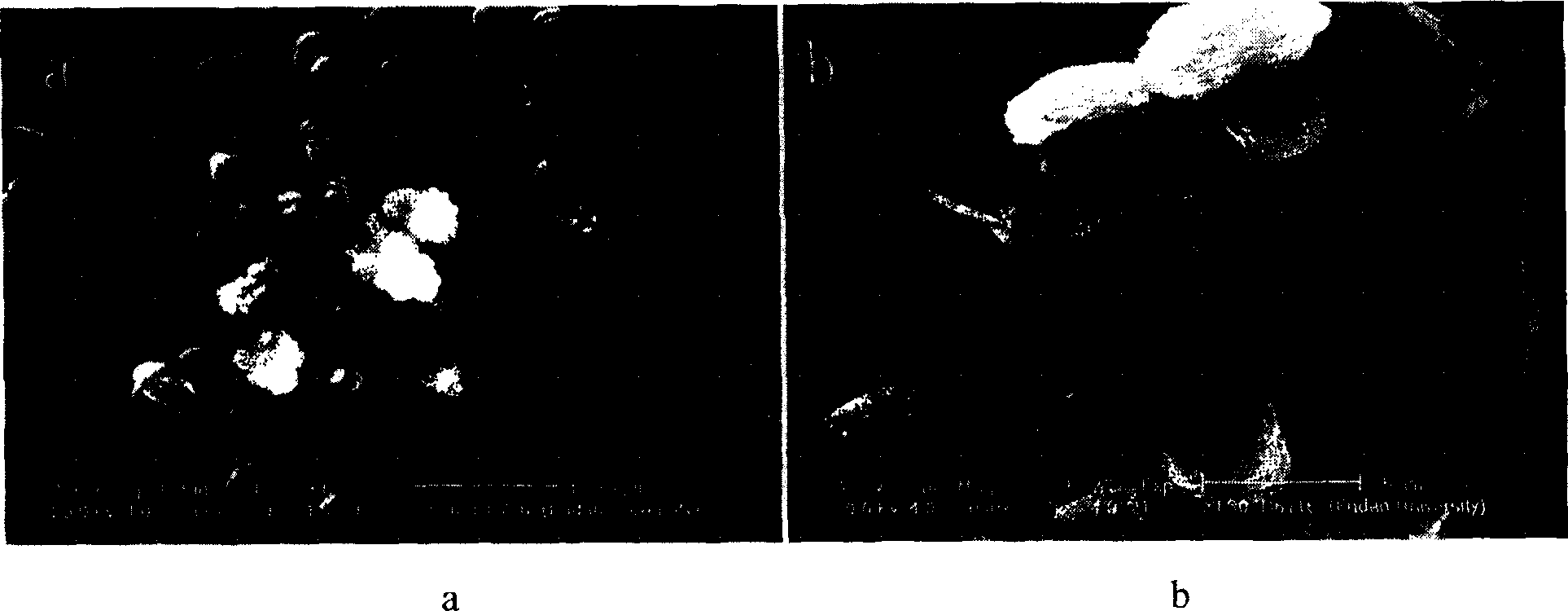

Examples

Embodiment 1

[0030] (1) Dissolve 0.5g o-phenanthroline in 80ml chloroform, stir vigorously at a speed of 4000rpm for 15min to make a carrier-containing liquid film, dry the cleaned microporous membrane and put it into the above liquid film system Take it out after soaking for 24 hours, clean the surface of the membrane with filter paper, put it into a reaction vessel, and form an isolation system with SLM in the middle and solution phase on the left and right, and an electric stirrer on each side of the membrane.

[0031] (2) prepare methyl orange content 40mg / L and Cd 2+ Content 0.1mol / LA solution, prepare methyl orange content 40mg / L and S 2- Content 0.1mol / L B solution, adjust the pH value of solutions A and B to 8-9, then add 80ml each of A and B solutions to the left and right sides of the SLM, and stir and react at 100-150rpm for 16 hours. Use atomic absorption spectrophotometry (GB7475-87) and methylene blue spectrophotometry (GB / T 16489-1996) to detect the contents of cadmium and ...

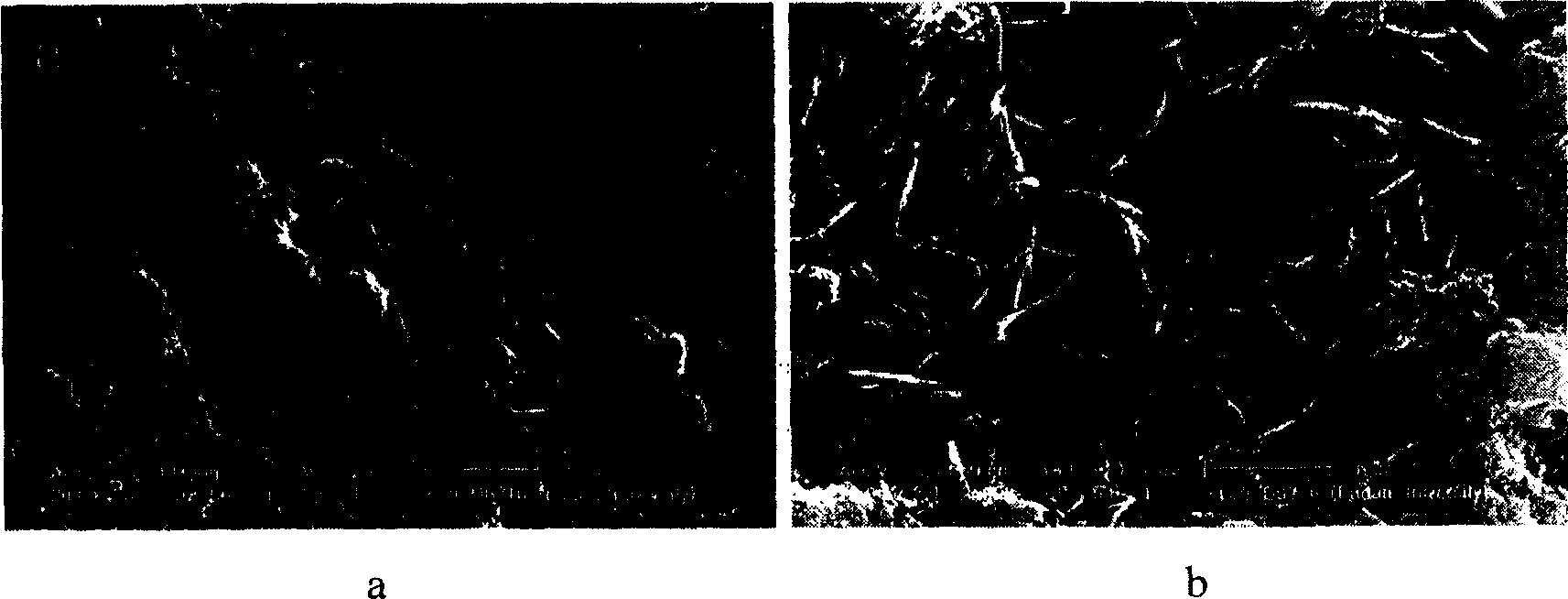

Embodiment 2

[0034] (1) Dissolve 0.3g o-phenanthroline in 70ml chloroform, stir vigorously at a speed of 3000rpm for 10min to form a carrier-containing liquid membrane, dry the cleaned microporous membrane and put it into the above liquid membrane system Take it out after soaking for 18 hours, clean the surface of the membrane with filter paper, and put it into a reaction vessel to form an isolation system with SLM in the middle and solution phase on the left and right, and an electric stirrer on each side of the membrane.

[0035] (2) prepare methyl orange content 60mg / L and Fe 2+ Content 0.01mol / LA solution, prepared methyl orange content 60mg / L, S 2- Content 0.01mol / L B solution, adjust the pH value of solutions A and B to 8-9, then add 60ml each of A and B solutions to the left and right sides of the SLM, and stir and react at 150-200rpm for 12h. Use flame atomic absorption spectrophotometry (GB11912-87) and methylene blue spectrophotometry (GB / T 16489-1996) to detect the content of i...

Embodiment 3

[0038] (1) Dissolve 0.2g o-phenanthroline in 60ml chloroform, stir vigorously at a speed of 2000rpm for about 20min to form a carrier-containing liquid film, dry the cleaned microporous filter membrane and put it into the above liquid film system Take it out after soaking in medium for 36 hours, clean the surface of the membrane with filter paper, put it into a reaction vessel, and form an isolation system with SLM in the middle and solution phase on the left and right, and an electric stirrer on each side of the membrane.

[0039] (2) Prepare methyl orange content 20mg / L, Ni 2+ Content 0.05mol / L A solution, prepared methyl orange content 20mg / L, S 2- Content 0.05mol / L B solution, adjust the pH value of solutions A and B to 8-9, then add 100ml each of A and B solutions to the left and right sides of the SLM, and stir and react at 120-160rpm for 12 hours. Use flame atomic absorption spectrophotometry (GB11912-87) and methylene blue spectrophotometry (GB / T 16489-1996) to detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com