Anti-cracking impervious agent and production method thereof

An anti-seepage agent and anti-cracking technology, which is applied in the field of anti-cracking and anti-seepage agents, can solve the problems of huge cost and consumables, crack resistance, flexural resistance, impact resistance and poor weather resistance and durability, so as to improve the later strength and reduce bleeding. Water-based, durability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

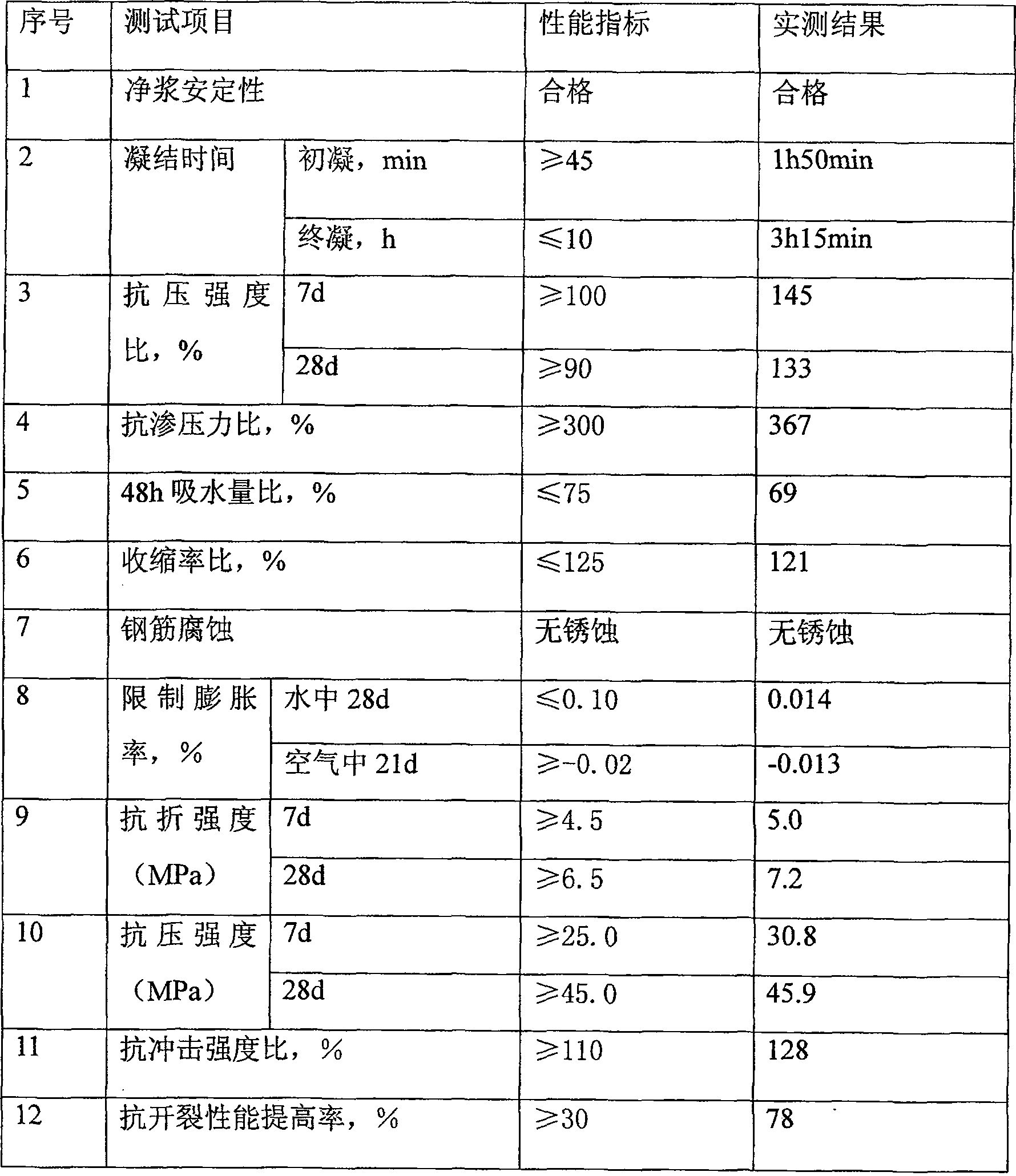

Examples

Embodiment 1

[0034] Embodiment 1, a kind of high-efficiency anti-crack and anti-seepage agent, its component and weight content are: activated zeolite powder 60%, silica fume 15%, calcium oxide 5%, magnesium oxide 5%, anhydrous sodium sulfate 8%, formazan Base cellulose ether 0.1%, sodium lauryl sulfate 2.9% and high-strength high elastic modulus polyvinyl alcohol fiber 4%.

[0035] The specific requirements for the above components are as follows:

[0036] Activated zeolite powder is obtained by grinding clinoptilolite with a pore size of 400 nanometers to 150 mesh, and removing crystal water at an ultra-high temperature of 800°C. The high-strength and high-elastic-modulus polyvinyl alcohol fiber has a diameter of 18 μm and a length of 6 mm. The silica fume is 7000 mesh silica fume.

[0037] All components in the anti-cracking and anti-seepage agent of the present invention are commercially available products.

[0038] The production method of above-mentioned anti-cracking anti-seepage...

Embodiment 2

[0042] Embodiment 2, a high-efficiency crack-resistance and anti-seepage agent, its components and weight content are: 80% of activated zeolite powder, 5.8% of silica fume, 3% of calcium oxide, 3% of magnesium oxide, 3% of anhydrous sodium sulfate, formazan Base cellulose ether 0.2%, sodium dodecylbenzene sulfonate 2% and high-strength high elastic modulus polyvinyl alcohol fiber 3%.

[0043] The specific requirements for the above components are as follows:

[0044] Activated zeolite powder is obtained by grinding clinoptilolite with a pore size of 600 nanometers to 200 mesh, and removing crystal water at an ultra-high temperature of 900°C. The high-strength and high-elastic-modulus polyvinyl alcohol fiber has a diameter of 20 μm and a length of 3 mm. The silica fume is 9000 mesh silica fume.

[0045] All components in the anti-cracking and anti-seepage agent of the present invention are commercially available products.

[0046] The production method of above-mentioned ant...

Embodiment 3

[0050] Embodiment 3, a high-efficiency crack resistance and anti-seepage agent, its components and weight content are: activated zeolite powder 65.7%, silica fume 10%, calcium oxide 8%, magnesium oxide 8%, anhydrous sodium sulfate 5%, formazan 0.3% of base cellulose ether, 1% of silane-based composite material and 2% of high-strength and high-elastic-modulus polyvinyl alcohol fiber.

[0051] The specific requirements for the above components are as follows:

[0052] Activated zeolite powder is obtained by grinding mordenite with a pore size of 500 nanometers to 250 mesh, and removing crystal water at an ultra-high temperature of 850°C. The high-strength and high-elastic-modulus polyvinyl alcohol fiber has a diameter of 19 μm and a length of 5 mm. Silica fume is made of 10000 mesh silica fume.

[0053] All components in the anti-cracking and anti-seepage agent of the present invention are commercially available products.

[0054] The production method of above-mentioned anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com