Method for preparing corn straw feed

A technology of corn stalks and production methods, which is applied in the direction of feed, animal feed, animal feed, etc., to achieve obvious environmental protection effects, solve the problem of sewage effluent, and have good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

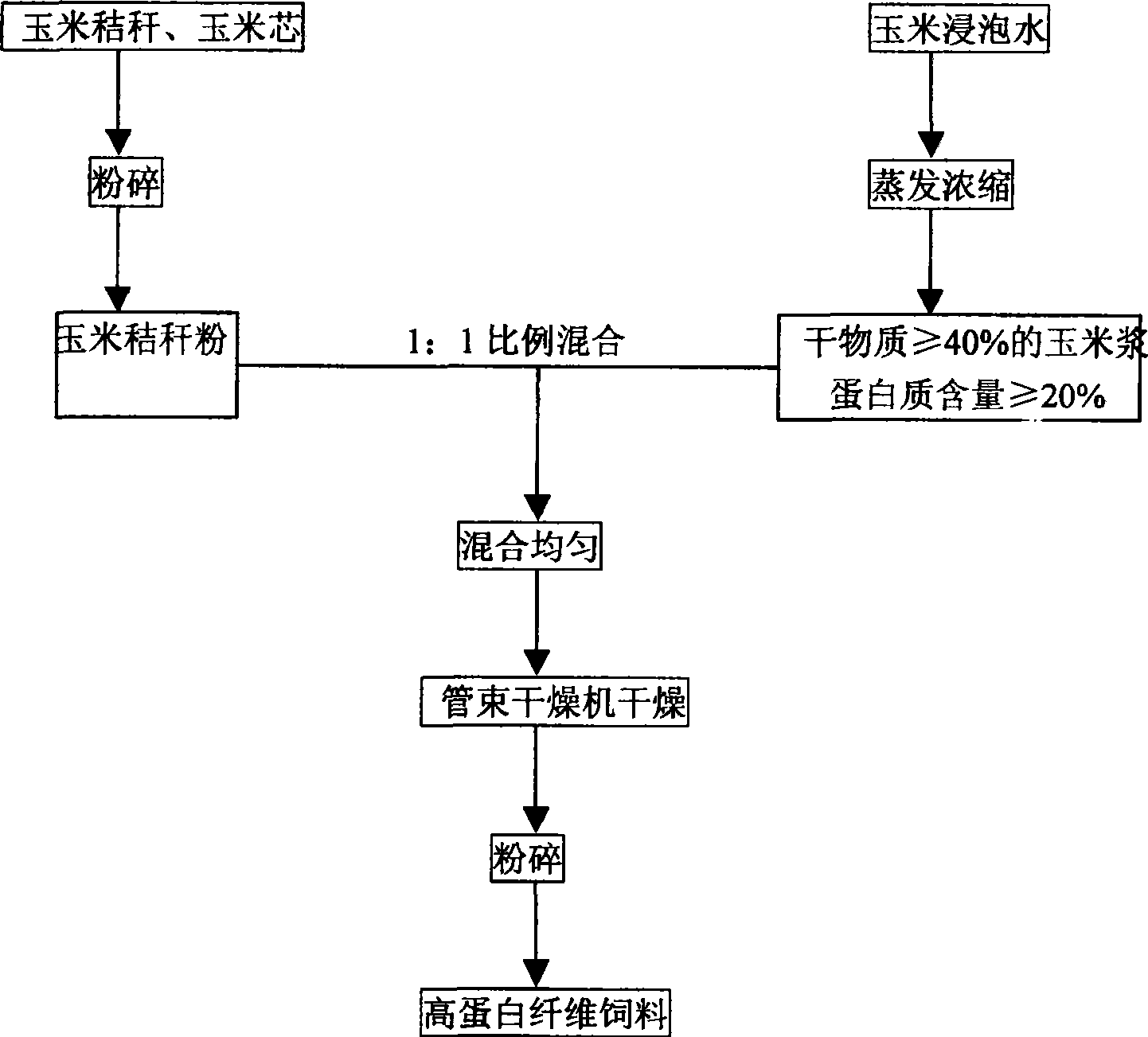

Image

Examples

Embodiment Construction

[0016] A kind of production method of corn stalk feed, the corn that concentration is 3.5Be ° is soaked in water earlier, and general displacement is 0.6m 3 / Ton (玉米) . The corn steep liquor is concentrated to a dry matter content of 40-42% by a three-effect vacuum evaporator and a protein content of 20-22%. Three-effect vacuum evaporator, the vacuum degree of each effect is controlled at: the first effect is normal pressure, the second effect is 460 mm Hg, and the third effect is 660 mm Hg; the evaporation temperature of each effect is respectively, the first effect is 98 ° C, the second effect is 75 ° C , Three-effect 53 ℃. Then crush the corn stalks and corncobs into 2-3mm particles, that is, corn stalk powder; then mix the corn stalk powder and corn steep liquor evenly at a ratio of 1:1, and then enter the tube bundle dryer for drying. The machine moisture is 40%, the outlet water is 10-12%, and the steam pressure in the tube bundle is 0.6MP a . Finally, put the dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com