Direct composite method for coating magnesium-alloy surface with nano-titanium dioxide

A nano-titanium dioxide, chemical composite plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of poor corrosion resistance, affecting development, etc., to improve compatibility, improve corrosion resistance, Good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

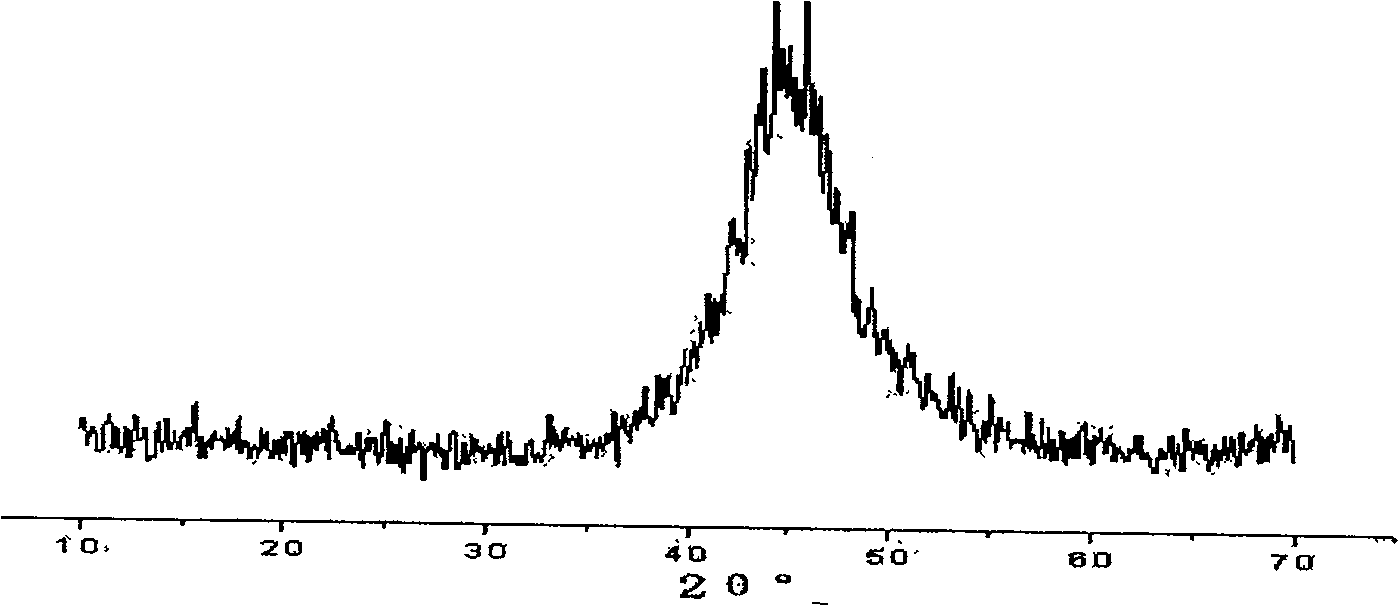

[0022] The method for direct nano-titanium dioxide chemical composite plating on the surface of magnesium alloy of the present invention comprises the following steps: (1) preparation solution, each component of plating solution is as follows, and the content of each component in every liter of solution is: NiCO 3 2Ni(OH) 2 4H 2 O 15g, 40% HF 12ml, citric acid or sodium citrate 12g, NH 4 HF 2 10g, complexing agent lactic acid 12g, stabilizer thiourea 0.5mg, NaH 2 PO 2 4H 2 O 25g, adjust the pH value of plating solution with ammoniacal liquor and hydrofluoric acid to be 6.0, and temperature is 90 ℃; The anatase type nano-titanium dioxide powder ultrasonic dispersion of 8g / l adds in the plating solution after 30 minutes, and stirs, makes Nano-TiO 2 The powder is uniformly suspended in the plating solution to obtain uniform Ni-P-TiO 2 Composite coating;

[0023] (2) Polish the magnesium alloy sample with 100-1000 sandpaper, then ultrasonically clean it for 10 minutes in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com