Special copper alloy and manufacturing method thereof

A copper alloy and alloy technology, which is applied in the field of new high-strength and high-conductivity copper-based alloys and their preparation, can solve the problems of material conductivity, high-temperature strength, high-temperature hardness, and softening temperature thermal strength without obvious improvement, and achieve high softening temperature , high conductivity, and high strength at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

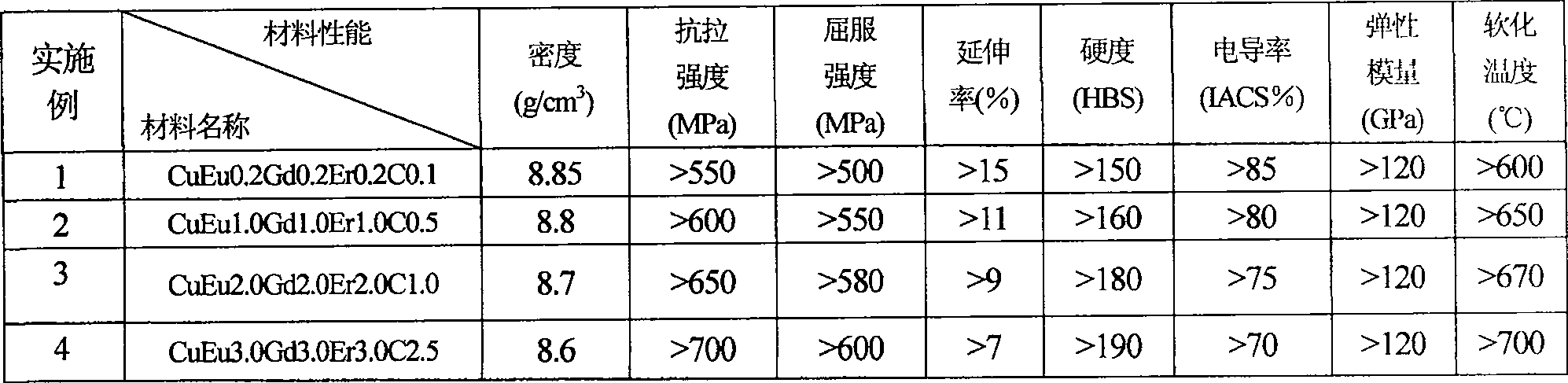

Examples

Embodiment Construction

[0023] The chemical composition (wt%) of the special copper alloy material of the present invention is: 0.01-5.0Eu, 0.01-5.0Gd, 0.01-5.0Er, 0.01-3.0C, and the balance is Cu.

[0024] The preparation method of special copper alloy material is characterized in that it includes the following process steps in sequence:

[0025] (1) In a vacuum intermediate frequency furnace (vacuum degree: >1×10 -2 Pa) Melting Cu, Eu, Gd, Er alloys in proportion;

[0026] (2) Under vacuum conditions (vacuum degree: >1×10 -2 Pa) at a cooling rate of 10 4 ~10 5 K / S atomizes the alloy liquid obtained in step (1) into powder;

[0027] (3) Mix the CuEuGdEr powder and graphite powder (C) in a mechanical alloying high-energy ball milling device for 24 hours;

[0028] (4) Pressing and forming the alloy powder obtained in step (3) under a pressure of 100-200 MPa;

[0029] (5) Vacuum sintering at 800~900℃ (vacuum degree: >1×10 -2 Pa) The alloy compact obtained in step (3);

[0030] (6) Then the CuEuGdErC alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com