Plastic surface vacuum plating process

A technology for vacuum coating and plastic parts, applied in vacuum evaporation coating, surface pretreatment, metal material coating process, etc., can solve the problems of restricting the safe use of plastic parts, semi-mirror effect that the film layer does not have a metallic texture, etc. The effect of achieving good insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

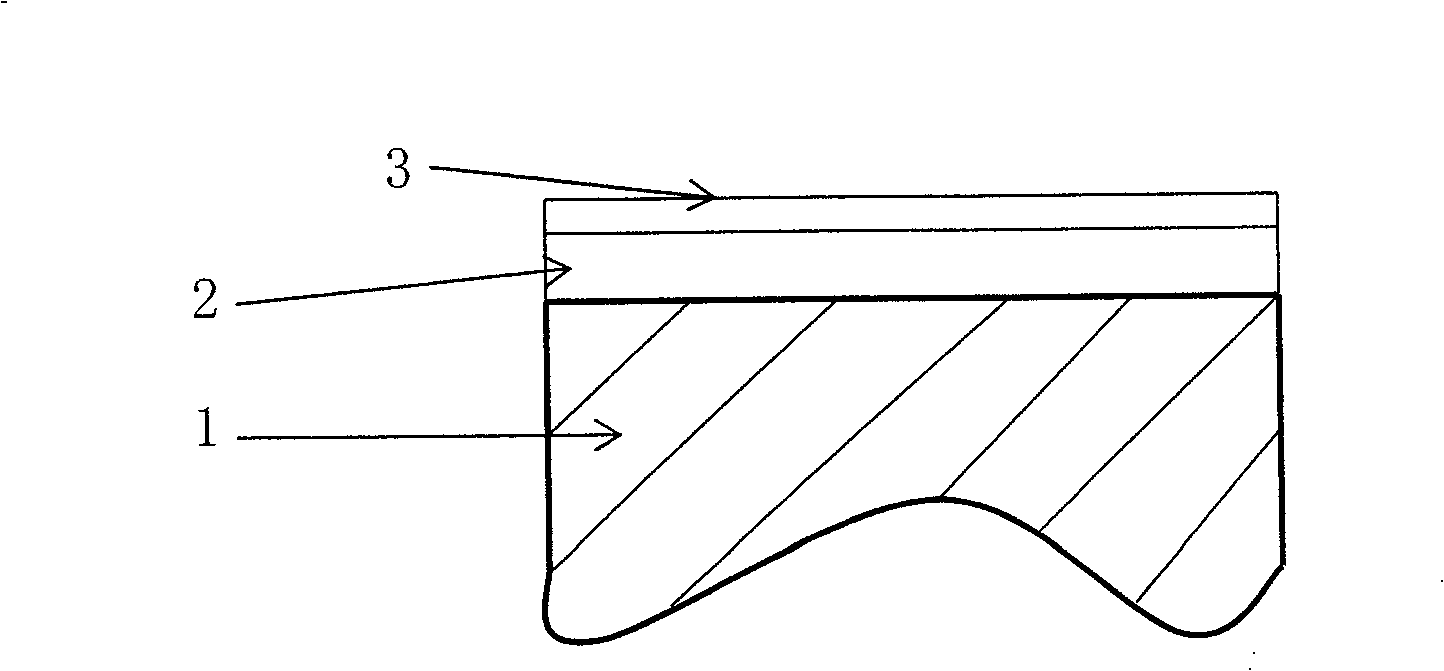

[0023] After cleaning the surface of the PC plastic part 1 by ultrasonic cleaning, spray a layer of UV primer 2 for vacuum sputtering, control the thickness of the paint layer to 5-20 μm, and then cure it under ultraviolet light; use zirconium metal as the target material for vacuum Sputtering, the sputtering process conditions are: coating power 9Kw, Ar flow rate 140Sccm, N 2 The flow rate is 65Sccm, and the coating time is 5 seconds. A zirconium nitride coating 3 with a film thickness of 10-30 nm was obtained. The coating had a metallic color and a semi-mirror texture, and its resistance value was determined to be infinite.

Embodiment 2

[0025] After cleaning the surface of the PC plastic part 1 by ultrasonic cleaning, spray a layer of UV primer 2 for vacuum sputtering, control the thickness of the paint layer to 5-20 μm, and then cure it under ultraviolet light; use zirconium metal as the target material for vacuum Sputtering, the sputtering process conditions are: coating power 9Kw, Ar flow rate 140Sccm, N 2 The flow rate is 150Sccm, and the coating time is 5 seconds. A zirconium nitride coating 3 with a film thickness of 10-30 nm was obtained. The coating had a metallic color and a semi-mirror texture, and its resistance value was determined to be infinite.

Embodiment 3

[0027] After cleaning the surface of the PC plastic part 1 by ultrasonic cleaning, a layer of primer layer 2 with a thickness of 5-20 μm is coated on the surface by immersion plating, and then cured by ultraviolet light; zirconium metal is used as the target material. Vacuum sputtering, the sputtering process conditions are: coating power 9Kw, Ar flow rate 140Sccm, N 2 The flow rate is 70Sccm, and the coating time is 5 seconds. A zirconium nitride coating 3 with a film thickness of 40-70 nm was obtained. The coating had a metallic color and a semi-mirror texture, and its resistance value was determined to be infinite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com