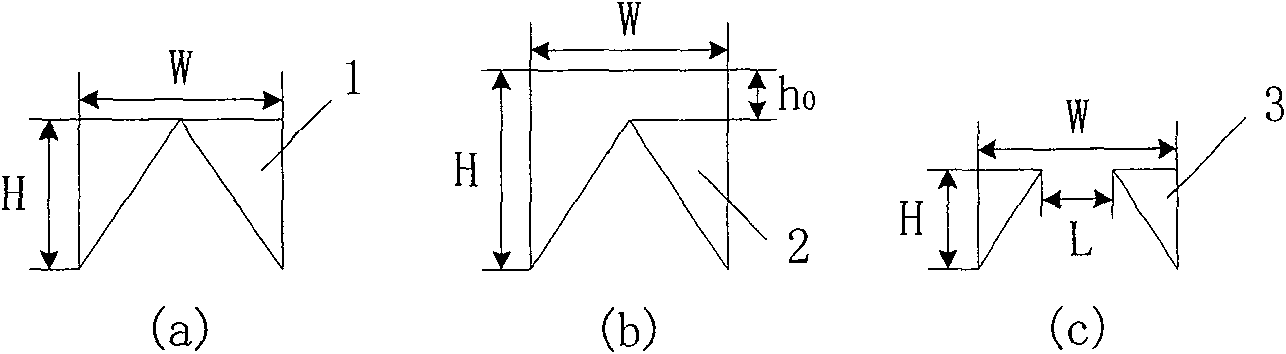

Cantilever structure and its making process and application

A cantilever beam and dry etching technology, which is applied in microstructure technology, microstructure devices, and manufacturing microstructure devices, etc., can solve the problems of increasing device cost, affecting device performance, and inconsistent beam thickness, etc., and achieve the improvement of manufacturing yield , The processing technology is simple, the effect of improving the control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

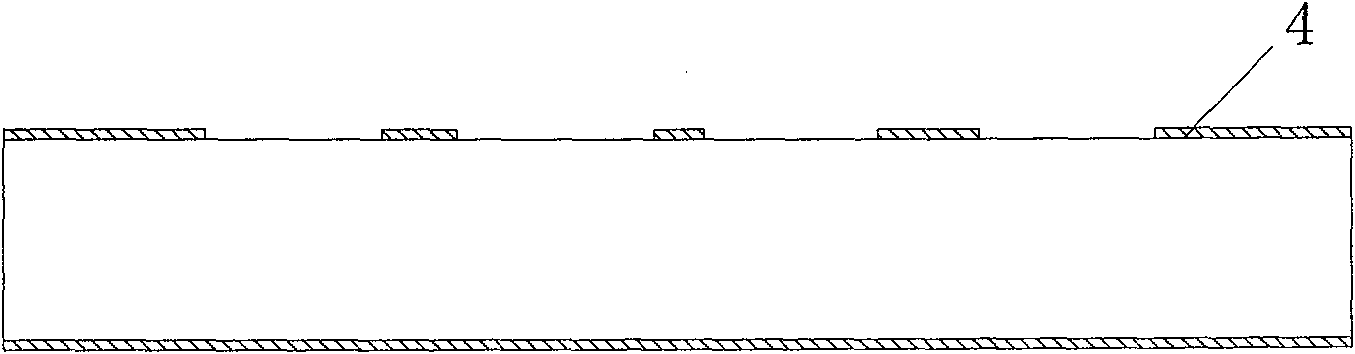

[0046] 1. Use photolithography on the upper surface of the oxidized double-throwing (100) silicon wafer to form a cantilever beam pattern ( image 3 );

[0047] 2. Corrosion of silicon oxide, dry etching of silicon; etching forms the two sides of the cantilever beam ( Figure 4 );

[0048] 3. On the surface of the silicon wafer after etching, cover a layer of silicon oxide to protect the upper surface and sides of the cantilever ( Figure 5 );

[0049] 4. Perform positive and negative alignment photolithography, and form a silicon etching window ( Image 6 );

[0050] 5. Perform anisotropic corrosion until the two corrosion termination surfaces (111) on the lower surface of the cantilever appear, forming the desired cantilever ( Figure 7 ).

[0051] The characteristic of this structure is that the lower surface of the cantilever beam will generate two (111) surfaces under the corrosion of the silicon anisotropic etching solution, as the surface of the cantilever beam th...

Embodiment 2

[0052] Embodiment 2 is used to make the elastic beam and mass block of acceleration sensor

[0053](1) The upper and lower surfaces of the oxidized double-polished (100) silicon wafer are made of damping gap windows by anisotropic etching method, and the etching depth is 4um;

[0054] (2) Secondary oxidation to form silicon oxide, double-sided photolithography, dry etching to obtain 4 straight elastic beams and movable mass at the same time;

[0055] (3) Three times of oxidation, photolithographic pattern on the back, and wet anisotropic etching to obtain straight elastic beams and movable masses at the same time. There are four straight elastic beams on the front side of the silicon wafer, which are distributed on the four corners of the movable mass.

Embodiment 3

[0056] Embodiment 3 is used to make the elastic beam and mass block of acceleration sensor

[0057] (1) The upper and lower surfaces of the oxidized double-polished (100) silicon wafer are made of damping gap windows by anisotropic etching method, and the etching depth is 4um;

[0058] (2) Secondary oxidation to form silicon oxide, double-sided photolithography, and dry etching on the front and back sides to obtain 8 straight elastic beams and movable masses at the same time;

[0059] (3) Three times of oxidation, photolithographic patterns on the front and back sides, and wet anisotropic etching to obtain straight elastic beams and movable masses at the same time. There are four straight elastic beams on the front and back sides of the silicon wafer respectively, which are distributed on the four corners of the movable mass block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com