Flame-retardant and its preparation method

A technology of flame retardant and catalyst, which is applied in the field of flame retardant materials and their preparation, can solve problems such as unfavorable environmental protection, and achieve the effects of low cost, good water solubility, and remarkable flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

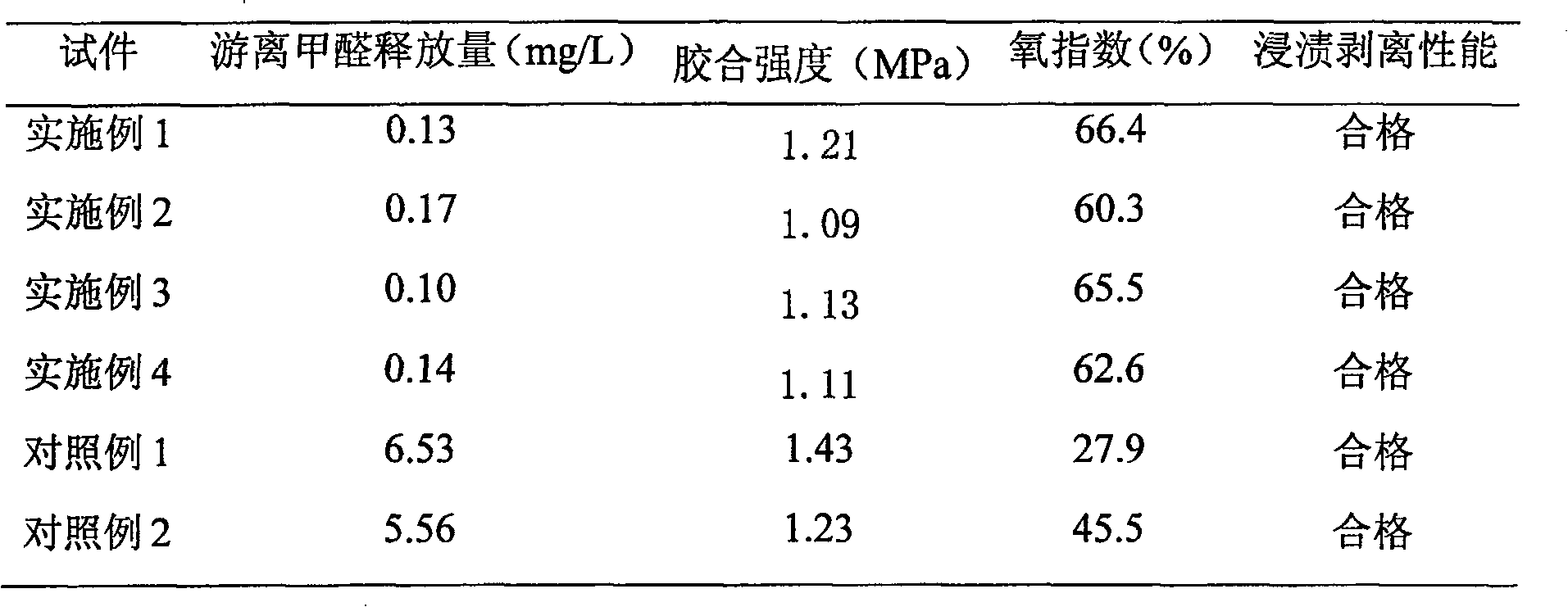

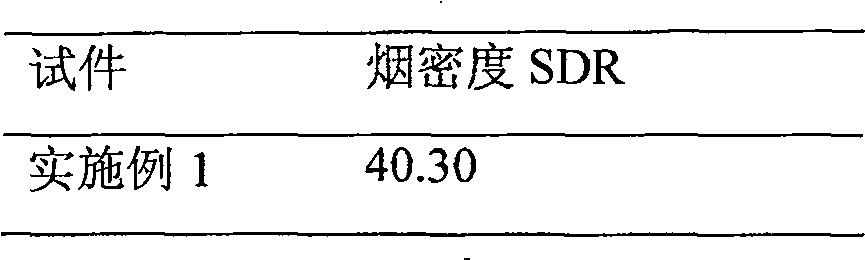

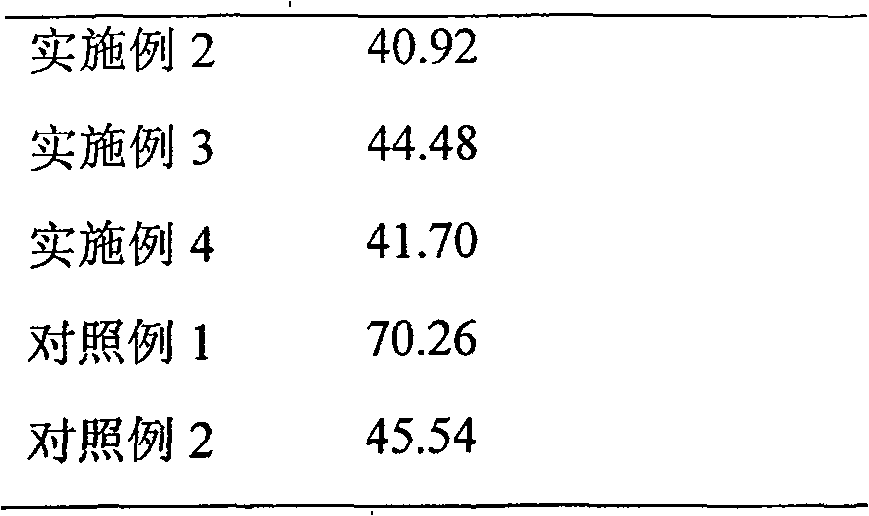

Examples

Embodiment 1

[0043] 1) Prepare raw materials according to the following weight ratio:

[0044] Demineralized water (hardness below 8 degrees) 1.3kg

[0045] Phosphoric acid (85% concentration) 1.0kg

[0046] Urea (content 99%) 0.5kg

[0047] Catalyst: 0.0035kg

[0048] Among them, the catalyst is a light yellow-green powder prepared by the Environmental Protection Flame Retardant Technology Center of the School of Materials Science and Technology, Beijing Forestry University. The raw materials include 1 weight part of tin chloride, 2 weight parts of copper sulfate, 1 weight part of sodium chloride, ferric chloride 1 part by weight, 1 part by weight of aluminum sulfate, 1 part by weight of boric acid, and 2 parts by weight of zinc chloride were ground uniformly and mixed.

[0049] 2) In a reaction kettle equipped with a stirrer, a thermometer and a condenser, add phosphoric acid in the reaction raw materials, stir and heat at the same time, the stirring speed is controlled at 50 rpm, and...

Embodiment 2

[0063] 1) Prepare raw materials according to the following weight ratio:

[0064] Demineralized water 1.8kg

[0065] Phosphoric acid (concentration is 85%) 1.3kg

[0066] Urea (content 99%) 0.54kg

[0067] Catalyst: 0.0038kg

[0068] The catalyst is the same as in Example 1.

[0069] 2) In a reaction kettle equipped with a stirrer, a thermometer and a condenser, add phosphoric acid in the reaction raw materials, stir and heat at the same time, the stirring speed is controlled at 50 rpm, and the temperature rises to 50°C;

[0070] 3) Add urea in the reactor, and continue to stir the mixture of phosphoric acid and urea at the same time, so that the material is distributed and heated evenly;

[0071] 4) Continue heating to raise the temperature to 115°C, slowly and evenly add the catalyst into the reaction kettle to make the mixture react;

[0072] 5) After continuing to heat until the temperature reaches 135°C, observe the reaction phenomenon while continuing to heat. As th...

Embodiment 3

[0083] 1) Prepare raw materials according to the following weight ratio:

[0084] Demineralized water 1kg

[0085] Phosphoric acid (concentration is 85%) 0.65kg

[0086] Urea (content 99%) 0.38kg

[0087] Catalyst: 0.0028kg

[0088] Among them, the catalyst is a light yellow-green powder prepared by the Environmental Protection Flame Retardant Technology Center of the School of Materials Science and Technology, Beijing Forestry University. The raw materials include 0.8 parts by weight of tin chloride, 2.5 parts by weight of copper sulfate, 1.2 parts by weight of sodium chloride, ferric chloride 0.8 parts by weight, 0.8 parts by weight of aluminum sulfate, 0.8 parts by weight of boric acid, and 1.5 parts by weight of zinc chloride were uniformly ground and mixed.

[0089] 2) In a reaction kettle equipped with a mixer, a temperature and pressure display, and a condenser, add phosphoric acid in the reaction raw materials, stir while heating, control the stirring speed to 70 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| release amount | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com