Method for preparing nano composite low melting point glass insulation coating

A low-melting-point glass and insulating coating technology, which is applied in the field of preparation of nano-composite low-melting-point glass insulating coatings, can solve the problems of high price, environmental pollution, and affecting the insulation performance of the coating, so as to improve the insulation strength and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

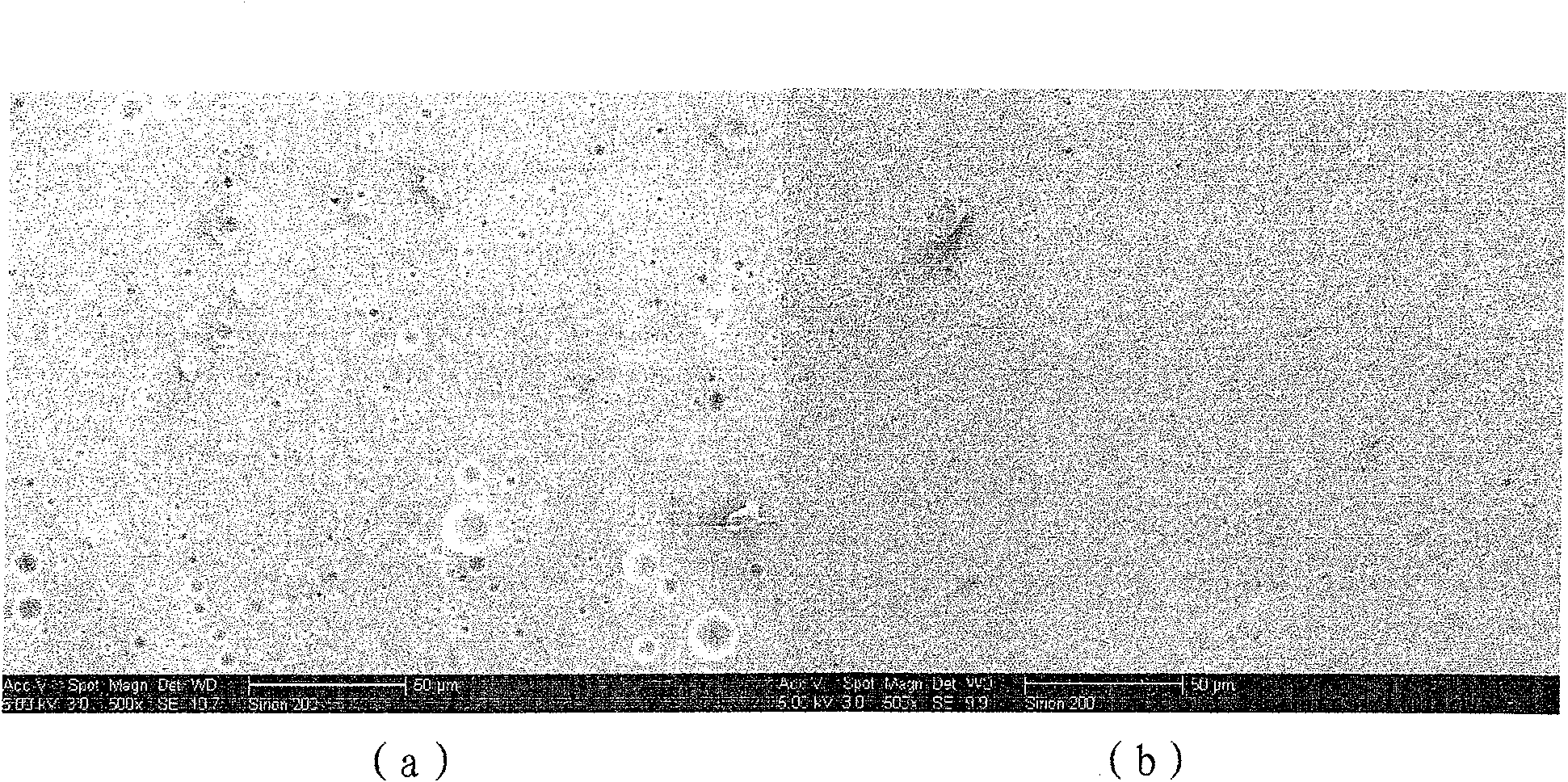

[0012] Embodiment 1: complete preparation according to the following steps: 1), first SiO 2 -B 2 o 3 Low-melting point glass powder and nano-ceramic powder are mixed with sodium silicate and deionized water (or distilled water) according to the ratio of 100:5:30:200; wherein, SiO 2 -B 2 o 3 Based on the low melting point glass powder, according to SiO 2 25wt%, B 2 o 3 10wt%, ZnO20wt%, CaO7wt%, MgO5wt%, BaO4wt%, Na 2 O15wt%, K 2 O13.4wt% and Al 2 o 3 The proportion of 0.6wt% is taken from the raw materials, mixed and ball milled for 5 hours, then melted at 1000°C for 80 minutes, and then quenched in water and ball milled for 5 hours to obtain a solid powder. The nano-ceramic powder is oxidized Aluminum powder. The mixture was then placed in a ball mill jar and mixed and ground on a planetary ball mill for 10 hours to obtain a mixed slurry. 2), first spin-coat (or spray or dip) the surface of the metal base copper (or semiconductor base or superconductor base) with the...

Embodiment 2

[0013] Embodiment 2: complete preparation according to the following steps: 1), first SiO 2 -B 2 o 3 Low-melting point glass powder and nano-ceramic powder are mixed with sodium silicate and deionized water (or distilled water) according to the ratio of 100:20:23:250; wherein, SiO 2 -B 2 o 3 Based on the low melting point glass powder, according to SiO 2 30wt%, B 2 o 3 25wt%, ZnO12wt%, CaO4wt%, MgO1wt%, BaO5wt%, Na 2 O13wt%, K 2 O9.7wt% and Al 2 o 3 The ratio of 0.3wt% is prepared to take raw materials, mix them and ball mill for 6.3 hours, then melt at 1100°C for 68 minutes, and then quench in water and ball mill for 6.3 hours to obtain a solid powder. The nano-ceramic powder is oxidized Aluminum powder. The mixture was then placed in a ball mill jar and mixed and ground on a planetary ball mill for 8.3 hours to obtain a mixed slurry. 2), first spin-coat (or spray or dip) the surface of the metal base copper (or semiconductor base or superconductor base) with the ...

Embodiment 3

[0014] Embodiment 3: complete preparation according to the following steps: 1), first SiO 2 -B 2 o 3 Low-melting point glass powder and nano-ceramic powder are mixed with sodium silicate and deionized water (or distilled water) according to the ratio of 100:35:15:300; wherein, SiO 2 -B 2 o 3 Based on the low melting point glass powder, according to SiO 2 35wt%, B 2 o 3 20wt%, ZnO8wt%, CaO9wt%, MgO6wt%, BaO3wt%, Na 2 10wt%, K 2 O7.8wt% and Al 2 o 3 The ratio of 1.2wt% is prepared by taking raw materials, mixing them and ball milling for 7.5 hours, then melting at 1200°C for 55 minutes, and then quenching in water and ball milling for 7.5 hours to obtain a solid powder. The nano-ceramic powder is oxidized Aluminum powder. Then the mixture was placed in a ball mill jar and mixed and ground on a planetary ball mill for 7.5 hours to obtain a mixed slurry. 2), first spin-coat (or spray or dip) the surface of the metal base copper (or semiconductor base or superconductor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com