Technique for treating wastewater of molasses alcohol

A technology of molasses alcohol wastewater and treatment process, which is applied in the fields of food industry wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc. Easy secondary pollution, good environmental benefits, and the effect of large organic volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

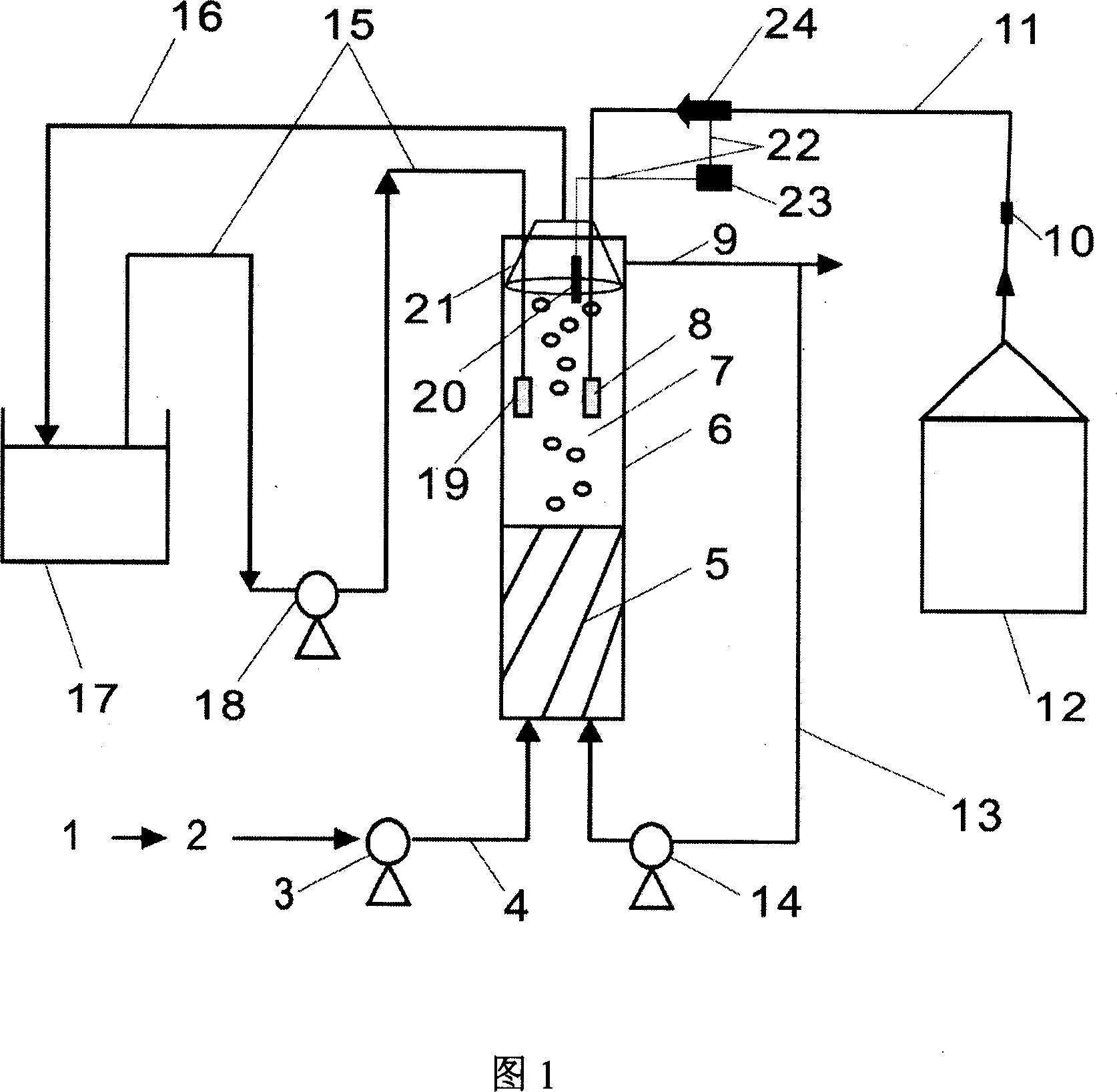

[0022] A small amount of oxygen is passed into the micro-aerobic reactor (6) with an effective volume of 12L from the oxygen tank (12), oxygen pipe (11), and oxygen aerator head (8), and the oxygen flowmeter (10), redox potential On-line controller (23), oxidation-reduction potential on-line controller probe (20), solenoid valve (24) control the oxygen intake of the reactor, so that the micro-oxygen reactor is in a micro-oxygen state with an oxidation-reduction potential of -390mV . Under the micro-aerobic state, the activated sludge rich in sulfate-reducing bacteria, methanogens and colorless sulfur bacteria is cultivated at the same time.

[0023] The molasses alcohol wastewater is adjusted to pH 6.7 and COD to 7900mg / L through the regulating tank (2), and enters the sludge bed of the micro-aerobic reactor (5) through the water inlet pump (3) and the water inlet pipe (4), and maintains the micro-oxygen reaction The hydraulic retention time in the device (6) is 12 hours; in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com