Environmental protective type inorganic, composite non-combustible plates, and manufacturing method

An inorganic composite, environmentally friendly technology, applied in chemical instruments and methods, building structures, building components, etc., can solve problems such as unfavorable mass production of machines, iron machines are easy to rust, magnesium chloride is easy to return to halogen, etc., and shorten the delivery time. time, improve overall performance, and overcome the effect of returning to halogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

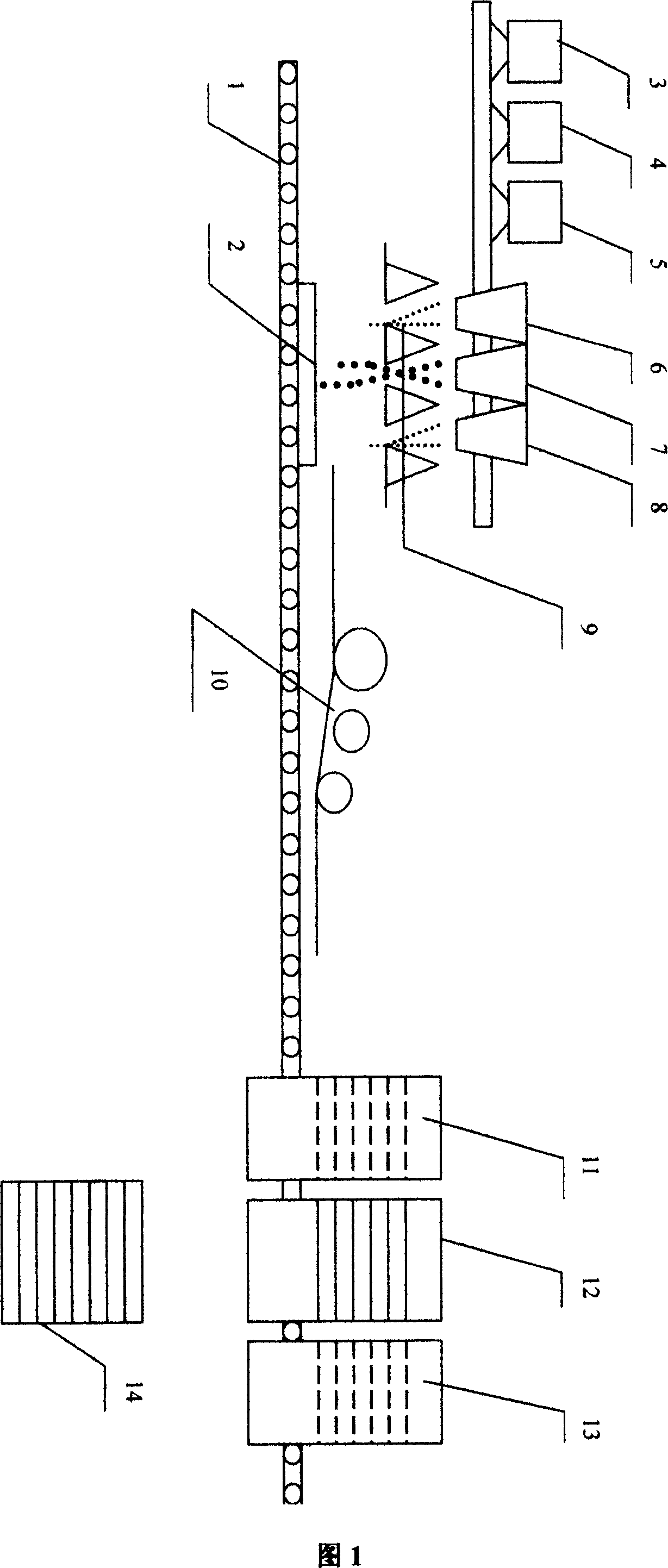

Method used

Image

Examples

Embodiment 1

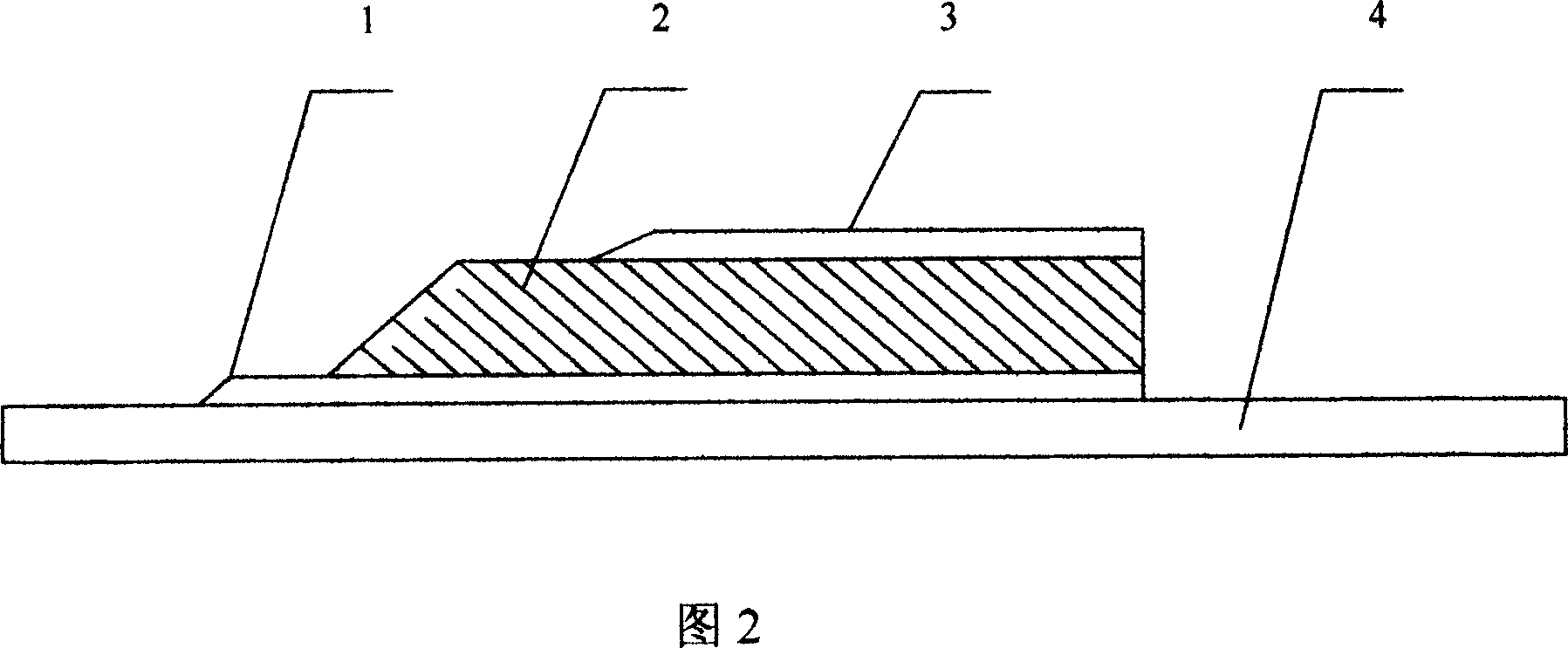

[0027] The raw material weight ratio of the environment-friendly inorganic composite non-combustible board provided by the present invention is: 40 parts of light-burned magnesium oxide; 40 parts of magnesium sulfate solution, mix the two, and then add 10 parts of fillers, which are fly ash and talcum powder , a mixture of aluminate cement (the specific gravity is 5:2:3), 40 parts of fibrous fillers are fibrous filaments such as bamboo silk and wood wool that are processed and discarded; 3 parts of water-resistant additives (using paraffin wax ); 3 parts of toughening agent (using water-soluble resin material); 5 parts of modifying agent (foaming material Baolilong ball), the above formula is produced by the above-mentioned mechanical manufacturing method, and it is 18mm finished product in 7 days of natural maintenance. The dry flexural strength is 15Mpa; the data obtained after immersing in water at 25°C for 30 hours and placing the specimen in an oven at 100°C-105°C for 2 ho...

Embodiment 2

[0029] 35 parts of lightly burned magnesia; 30 parts of magnesium sulfate solution; 10 parts of filler (the proportion of fly ash, talcum powder, and aluminate cement is 5:2:3); 45 parts of fibrous filler; water-resistant additive 3 parts (using phosphoric acid); 3 parts of toughening agent; 5 parts of modifier. The above formula is produced according to the above-mentioned mechanical manufacturing method. After 6 days of curing, the dry bending strength of the 10mm finished product is 18Mpa; the moisture absorption deformation rate is 0.21%; it is placed in a 95-100% humidity box at 25°C for 30 days. Small drops of water appeared.

Embodiment 3

[0031] 40 parts of lightly burned magnesia; 35 parts of magnesium sulfate solution; 15 parts of filler (the specific gravity of fly ash, talcum powder, and aluminate cement is 7:3:5); 25 parts of fibrous filler; water-resistant additive 2 parts (using phosphate); 5 parts of toughening agent; 3 parts of modifier. The above formula is produced according to the above mechanical manufacturing method. After 6 days of curing, the dry bending strength of the 18mm finished product is 14Mpa; the moisture absorption deformation rate is 0.11%; it is placed in a 95-100% humidity box at 25°C for 30 days. Small drops of water appeared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap